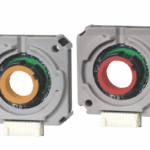

RSF Elektronik’s next-generation kit angle encoders for motion feedback are best suited for applications in robotics, semiconductor, medical and machine tool. Offered through parent company HEIDENHAIN CORPORATION in North America, this new encoder is available in both absolute (MCR 15) and incremental (MSR 15) versions. Both models consist of an optical scanning unit and a separate full circle drum with the graduation on the outer diameter.

The new absolute MCR 15 and incremental MSR 15 encoders are available in several sizes of drums, from an inside diameter of 40 mm up to 330 mm. The drums come with accuracies starting at 20 arc seconds with up to 10 arc second, depending upon diameter. Resolutions are also diameter-based and range from 22 to 25 bits for the absolute versions. Resolutions of the incremental versions start at 4,740 lines per 360 degrees all the way up to 27,540 for the largest diameter.

The RSF encoder drums provide bolt-hole pattern for mounting that is compatible with other encoder drum manufacturers. Maximum revolutions per minute on the large diameter is 870, and the smallest diameter can be spun up to 12,200 times per minute. If a full 360 degrees of rotation is unnecessary, then segments of the graduation itself are available.

Both the MCR and MSR 15 scanning units come with a colored status LED that indicates the operating and mounting condition. Interfaces available include the analog 1-V peak to peak, digital TTL with up to x200 interpolation, and for the absolute encoders, ENDAT, Fanuc, Yaskawa, Mitsubishi and Panasonic. The scanning units can withstand a larger operating temperature specification as well, from -10 °C up to 70 °C. A mounting tool is available to help install the scanning units onto the machine axis with precision and ease.

For more information, visit https://www.rsf.at/en/ or www.heidenhain.us/about.us/.

Leave a Reply

You must be logged in to post a comment.