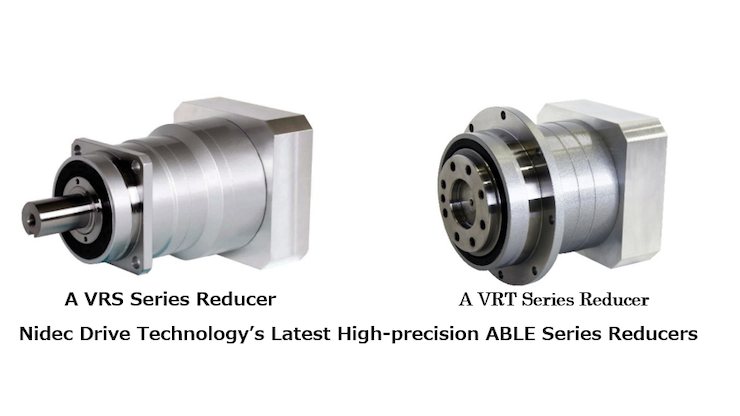

Nidec Drive Technology has added high-end models that feature low backlash, noise, and vibration, to the company’s lineup of the ABLE series, a group of servo motor-dedicated planetary reducers.

“ABLE reducer” is the trade name of the group of servo motor reducers that Nidec Drive Technology sells. The latest models that the company has newly developed adopt tooth-surface grinding gears. Tooth-surface grinding is a method to grind a gear’s tooth surface with a grinding stone. Other grinding methods include gear cutting, shaving, and skiving, but the tooth-surface grinding method can secure better levels of precision.

High-end laser beam machines, machine tools, woodworking machinery, and other mechanical products require highly accurate positioning, and a reducer’s backlash and vibration directly affect such products’ precision. Nidec Drive Technology’s latest products, whose tooth surfaces were ground with the newest models of Nidec Machine Tool Corporation’s globally renowned gear grinders, have achieved better performance levels while driving down cost.

Nidec Drive Technology stays committed to providing various business fields with high-efficiency industrial machines that utilize the company’s continuously variable transmission-based know-how, to contribute to productivity improvement and automation.

For more information, visit www.nidec.com.

Leave a Reply

You must be logged in to post a comment.