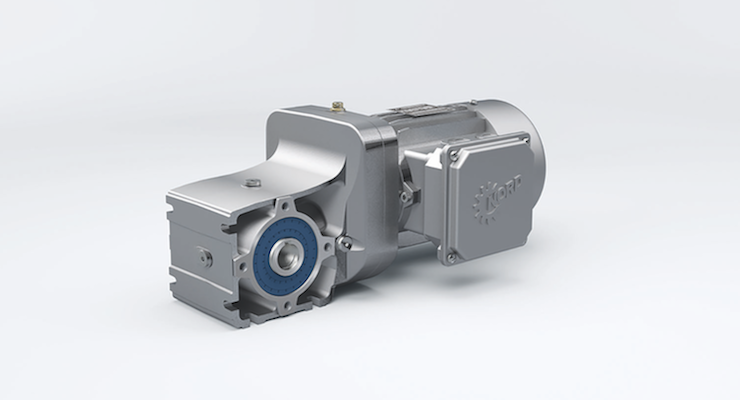

NORD’s new SK 920072.1 two-stage helical bevel gear motor (mounted with a NORD motor) is a drive solution for a wide range of light duty conveying, processing and manufacturing applications. Identified by its high-strength and light-weight design, NORD’s newest aluminum gear motor is a cost-effective replacement for cast iron units. Two housing styles offer options for multiple applications and environmental conditions.

The next size of premium efficient two-stage bevel gearboxes features a new compact, more efficient modular design. Covering applications for torques up to 443 in.-lb (50 Nm) and offering up to 97 percent gear efficiency, the SK 920072.1 and SK 930072.1 are superior alternatives to worm gear units in light conveying and processing applications, as well as for food and beverage industries.

Like other NORD gearmotors, the new size comes in two housing designs – the SK 920072.1 has optimized thermal properties due to its large surface area. The SK 930072.1 is ideal for washdown applications because of its closed housing design.

The new NORD size has a power range of 0.16 to 1.50 hp (0.12 to 1.1 kW) and speed ratios from 3.03 to 47.67. They provide exceptional adaptability for all mounting positions as far as input, output and motor options. Available with either NEMA or IEC input, a NORD motor or brake motor, both the SK 920072.1 and SK 930072.1 gear units are well suited for use in the material handling industry, car wash, as well as for sanitary and hygienic environments.

Available for the SK 930072.1 model is NORD’s NSD TUPH surface conversion, a revolutionary process only offered by NORD. The aluminum alloy reducer housing and modular accessories are electrically catalyzed producing a strong corrosion resistant base layer (or molecular surface conversion). The additional top layer provides enhanced sealing, additional corrosion protection and a brighter finish.

Unlike painted cast iron gear units, the extremely strong base layer (six to seven times harder than the original aluminum alloy) provides superior corrosion resistance and scratch resistance, and it will not chip, flake or rust.

With NORD’s leak-free design, longer gear and bearing life, quiet operation, and precise output torque capabilities, SK 920072.1 and SK 930072.1 helical bevels deliver high efficiency operations, low maintenance, and longer service life.

For more information, visit www.nord.com.

Leave a Reply

You must be logged in to post a comment.