Functional safety is a fundamental component in drive systems. The SK TU4-PNS, known as the PROFIsafe module, provides comprehensive safety for the reliable operation of NORD drive systems. This PROFIsafe module is a drive-integrated solution for decentralized variable frequency drives that implements functional safety within the system to stop operation and avoid potential injuries or component damage.

While all frequency drives from NORD have integrated STO (Safe Torque Off) and SS1 (Safe Stop 1) functions, PROFIsafe includes even more safety features. Functions such as SLS (Safely Limited Speed), SSR (Safe Speed Range), and SSM (Safe Speed Monitor) are incorporated into the drive units to provide safe stop functions that protect operators and prevent damage to the drives and materials. These functions, as well as SDI (Safe Direction) and SOS (Safe Operation Stop), achieve SIL 3 (Safety Integrity Level 3) or PLe (Performance Level 3) Category 4.

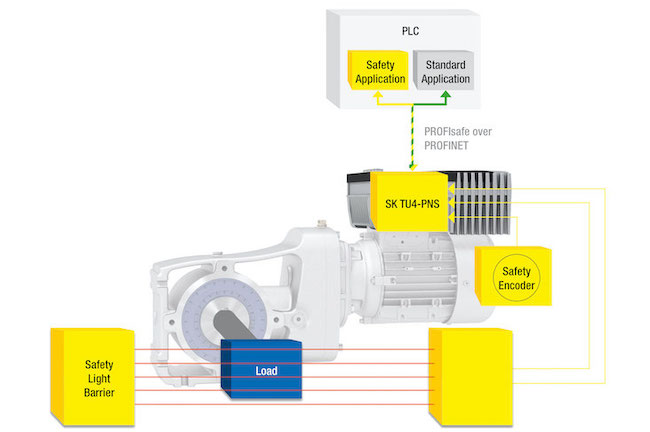

The PROFIsafe bus system communicates via PROFINET and can be monitored by connecting an encoder to the drive. Safety input and output components can also be connected directly to the module. The module monitors the drive data and if a limit value is surpassed or not met, the bus system reacts and switches the drive to a safe state. The voltage is then disconnected from all outputs and the input information is reset and transmitted to the secure controller. With this, the PROFIsafe module provides extensive safety for reliable operation.

For more information about NORD’s PROFIsafe solution, visit www.nord.com.

Leave a Reply

You must be logged in to post a comment.