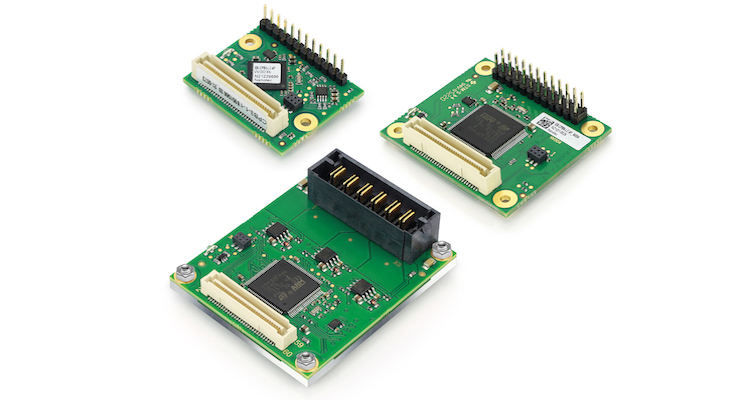

The small plug-in motor controllers of the CPB series from Nanotec are easy to integrate into existing applications and customer boards. Available in three sizes with rated power of 150, 300, and 750 W, they have the same features and identical pin assignments on the logic connector. As a result, several performance classes of a customized carrier board or multi-axis board can be realized.

Together with extended features such as the acceleration feed-forward and jerk-limited ramps, the field-oriented torque, speed and position control provides optimum dynamic performance and cycle time. In addition to motor feedback via Hall sensors, incremental encoders or SSI encoders, it’s also possible to integrate a second rotary encoder.

As the hardware wiring for the fieldbus, the input/output and the encoders is provided on the carrier board, the controllers can flexibly be adapted to individual requirements. Supporting the most common protocols such as EtherCAT, CANopen, Modbus TCP, and Modbus RTU, they are highly versatile.

With a rated current of 3 A / 6 A / 15 A and peak currents of 9 A / 18 A / 45 A, the modules are compatible with both small and larger BLDC and stepper motors.

For the evaluation and test phase, Nanotec offers various carrier boards on request.

For more information, visit us.nanotec.com.

Leave a Reply

You must be logged in to post a comment.