In this two-part series, we go over the basic definition of types of repeatability and their application in linear motion and actuation applications. Part 1 covers unidirectional repeatability.

Information courtesy of IntelLiDrives Corp.

Effectively automating any industrial operation, test procedure, or prototype process involving motion requires determining the movement precision needed to yield acceptable results.

A motion system ideally positions to a given target point with some small amount of tolerance or uncertainty. However, motion system performance is specified by many factors affecting performance.

Repeatability, positioning accuracy and resolution primarily determine precision. Understanding these parameters, their causes, and their influence on system performance is essential in determining the capability needed in a given application and specifying the appropriate motion components.

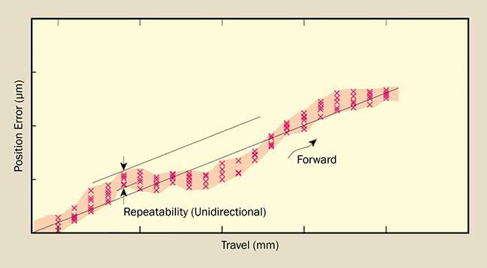

One way to look at repeatability is the tolerance within which a positioner returns to a particular location. Unidirectional repeatability defines performance for approaches from only one side of the target. Bidirectional repeatability defines the performance for approaches from either side of the target.

Contributing factors to repeatability include system friction, torsional stiffness, load, acceleration, and backlash.

Repeatability, the most fundamental standard of system performance, defines the variation in results for a series of moves or, more analytically, the width of the dispersion about the mean for a significant number of positioning trials. Repeatability, a statistical quality, is commonly defined for a normal distribution by the dispersion width corresponding to a number of standard deviations.

Usually, three-standard deviation repeatability (3 Sigma) is specified. Consider, for example, a positioning system with a repeatability specification of 0.0001 in. For 3 Sigma specification, any series of identical movements will fall within a dispersion width of 0.0001 in. with 99.74 confidence. By way of comparison, 2 Sigma equates to a 95.44 confidence, while 6 Sigma corresponds to a 99.9997 confidence interval. Frequently, motion systems are only required to demonstrate consistency or minimal variability to provide uniformity of the resulting product. In such cases, repeatability is the only attribute necessary to satisfy the precision requirement.

Unidirectional repeatability involves approaching the target position from only one side. It’s affected by non-constant static friction, termed stiction, and the degree of torsion stiffness in the drive train. Stiction gives rise to movement characterized by a breakaway jump as force is applied to initiate motion, while inadequate torsion stiffness causes windup, which is motion input without a corresponding output displacement.

Leave a Reply

You must be logged in to post a comment.