By Tom Jensen

ELAU Packaging Solutions

Schneider Electric

Packaging robots execute tasks not found in other applications, so it would not suit to use program practices geared for an automotive or welding robot. Here’s a look at control strategies specific to packaging.

What distinguishes a packaging robot from welding, material handling, painting and assembly robots, or the traditional SCARA, portal and articulated robot configurations with teach pendants mounted in safety cages out on the plant floor? For the most part, those industrial robots move heavy objects from Point A to Point B using mechanical end effectors to handle loads at relatively low speeds, constantly looking for collisions.

When a robot moves an engine block, programming issues revolve around picking up the block and moving it to a new position. Welding applications typically use an articulated robot with a wrist that necessitates that all six axes must synchronize around a radius – the tool center point (TCP).

Packaging applications rarely requires these two tasks – with the exception of a palletizing robot, which is a material handling or tertiary packaging application, since both primary and secondary packaging have been completed. Packaging robot configurations tend to be three-dimensional (delta 3) and two-dimensional (delta 2) arm configurations.

You could program a packaging robot using the same approaches used in automotive or welding, but a different control strategy works better.

The packaging difference

Belt tracking, belt collation, path planning, acceleration control, and customer specific kinematics are motion tasks specific to packaging.

Belt tracking — In many packaging applications, it is critical for a conveyor belt to keep moving. Therefore, a robot must track belt motion and calculate where a product on the belt will be after it is detected. This task often requires that a robot operate in a three-dimensional space; picking objects from a belt, orienting them, and placing them into a tray or case. In some cases, though, the size of the object (more than 1 lb) will require the use of a two-dimensional robot.

Belt collation — such as the classic dual belt – is found in 70% of packaging applications. Two dimensional robots are used here because you must stage the product.

Two dimensional robots with collation can perform several complex tasks.

Path planning — Collisions are not a high concern in packaging because the robot is harmonized with the rest of the equipment. But you are operating at high speeds — say, 70 picks per minute — so an optimal path can yield higher productivity.

In path planning, you draw a spline through space for the shortest distance and smoothest accelerations through that space, then store that as a planned path. From that path, the robot goes to pick positions and place positions with a standard software cam profile.

If you have programmed robots in automotive applications, for example, you probably used a teach pendant. This technique works in packaging too, but may not always be efficient for high speed operations.

Acceleration control — Once the path is planned, you command the robot to run it at a programmed speed. What speed is right? A customer may arbitrarily calcu

late a speed of 60 picks per minute. But they don’t know the G force at the vacuum point and on the product, so they can end up damaging or losing control of the product by applying excessive G force.

Acceleration (G force) control is a software function for programming the robot to a maximum speed while maintaining a specific G force in all control dimensions (up, down, front, back).

Customer kinematic — Off-the-shelf robots typically use a standard control package that includes program features for kinematics. Such a package, however, tends to limit an OEM’s flexibility to program the robot to a specific application not included in the standard package. Other robot designs encounter the same limitation, such as a global robot or a robot on a pedestal combining up and down and portal movements with a rotating base, a configuration often used for tool changers in CNC machines.

You could take a three-axis robot and add it to one of these robot formats. But a packaging robotic system is not just about adding robot types together, but adding uncommon mechanics — such as a crank transformation — to achieve a complex mechanical motion.

With many packaging robot systems, the control of all the different planes in space is core to the packaging machine, enabling the customer to program whatever is needed. Any unusual collection of mechanics can be changed into dimensions with however many degrees of robotic freedom, and programmed. The software that handles such programming is known as transformations. It gives the customer a way to articulate their kinematic.

Example packaging applications

Rainbow packs are the multi-flavor packs of beverages, yogurt, confections, snacks and other single serving size products. For profitability, they are largely repacked by hand at distribution centers and co-packer facilities — adding cost, time, the potential for shrinkage, and sometimes less than ideal secondary packages. As long as club stores and other influential retailers demand these variety packs, there will be a need to repack them more cost-effectively.

One way to handle this task is with robots, but not the familiar articulated robots found in palletizing and sometimes case packing applications. Instead, delta 2 and gantry-style robots make the most sense, along with sophisticated end of arm tooling that may be equipped with vacuum and servo actuation.

The XPAK USA, LLC introduced the Variety Pack Assembly System (V-PASS) at the most recent Pack Expo show using servo automation systems. The robot mechanisms descend upon filled single-flavor multipacks, pluck groupings out, and repack them into the openings it has created. The system suits smaller, regional contract packagers who make up the bulk of food industry co-packing.

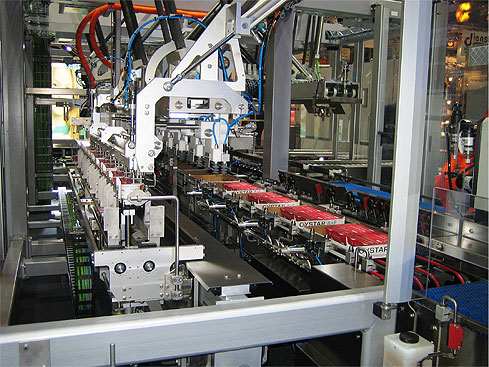

On the opposite end of the spectrum is OYSTAR A+F’s massive SetLine packaging and sleeving machine. In operation at Germany’s Interpack show, the SetLine comprises three sets of twin delta 2 robot arms, two carriages on parallel tracks, and in rainbow configuration with up to four infeed conveyors.

The first robot picks four groups of three tubs of one flavor from a tray on the first input conveyor. The tooling expands to place one tub into each of four fixtures. The robot arm then picks from the infeed conveyor until all four flavors are transferred into variety pack configurations.

Then the carriage indexes to the next station where a sleeve is picked, erected into the carriage and filled with cups by a second robot. At Station 3, a robot glues and seals the filled sleeves and places them into the trays on a discharge conveyor.

The SetLine machine is the ‘big brother’ of A+F’s TwinLine twin axis robot, believed to be the very first case packing delta 2 robot. It fits larger packaging operations, including food processing plants where products may be diverted from dedicated single flavor filling lines after tray/case packing to a separate rainbow line. The SetLine machine can just as easily be configured to pack single flavors on the main packaging lines.

The trend in packaging has been to shift away from third-party, general purpose robots in primary and secondary packaging applications to embedded robots implemented by packaging machine builders. Embedded robots are compact, offer good payloads and freedom of movement, are highly synchronized with the rest of the packaging machine, and they are applied with the OEM’s knowledge of the packaging process.

Case packing in particular has benefited from compact, self-contained delta 2 robots. A delta 2 robot from Nuspark Engineering Inc. can case pack, de-case empty bottles for filling, or orient and transfer packages from one belt to the next. A second arm can fit on the same frame, doubling throughput without any increase in footprint.

In all of these examples, an IEC-compliant automation control system replaces the traditional proprietary ‘black box’ robot controllers. Where complex kinematic algorithms are required, these are calculated behind the scenes, so programming is the same as for ‘normal’ servo packaging machines.

ELAU Packaging Solutions,

Schneider Electric

www.schneider-electric.us/solutions/packaging/

Leave a Reply

You must be logged in to post a comment.