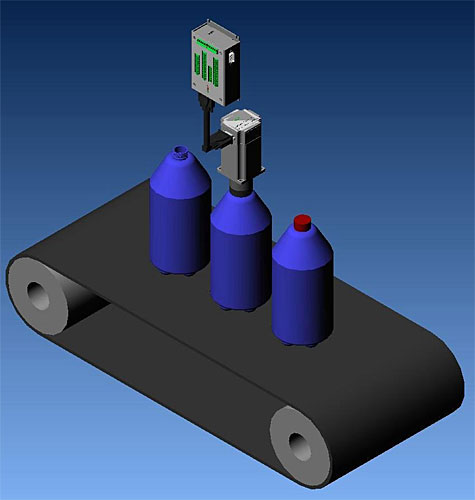

The most common tightening applications are caps or nuts. These types of applications require accurate control of torque and position to avoid stripping, under tightening, over tightening, missing bottles, cross-threading, and mechanical jams.

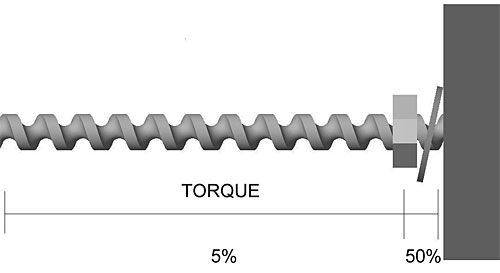

QuickSilver’s programmable single axis servo motor controller can be pre-loaded with the expected/nominal torque profile. If more or less torque is detected for a given position, a fault can be generated notifying the operator of the problem.

QuickSilver’s high torque, direct driver brushless servo motors are ideal for this type of application. Available in NEMA 11, 17, 23 and 34 frame sizes to cover most tightening needs. They have superior holding torque over traditional servo motors which gives them the advantage when “snugging” down those caps or nuts.

For even more torque control, the servo motor controllers are capable or reading in an analog voltage from a load cell or torque sensor and use it to fine tune the motor’s torque.

Leave a Reply

You must be logged in to post a comment.