Schaeffler group (www.schaeffler.de) has announced that its latest product development for the industrial sector is the ball roller bearing and the roller bearing.

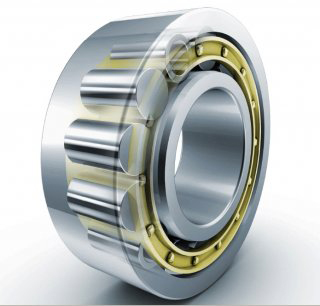

Tube roller bearing is a conventional cylindrical roller bearing that is used at a specific running condition. It has been adapted so that three rollers are larger in diameter than the normal and are made as hollow tube rollers.

The purpose of this feature is to enable the bearing to withstand a wide range of loads.

It only uses three hollow rollers when the loading is low to keep the rolling elements rotating through a slight preload in the contact surfaces. The hollow rollers will flex slightly without surpassing the steel’s elastic limit when the load suddenly becomes heavy.

”Underloading a bearing can be just as damaging as overloading because, when the load is not heavy enough, the rollers slide or skid instead of turn. The hollow roller bearing is particularly suited to steel mill applications, where the load varies substantially,” said Eugene Nortje, field service engineer of Schaeffler South Africa.

The ball roller bearing is almost the same to the average ball bearing; the only difference is that 15 percent of the ball rollers’ side has been ground down, which results in a ball bearing that is 30 percent narrower than the average.

”The recession spurred this movement as plant owners tried to save money by maintaining their plant instead of buying new bearings, and lubrication plays a key role in bearing maintenance,” added Nortje.

Leave a Reply

You must be logged in to post a comment.