Updated February 2020. || Selecting the right cable for an application starts with a few fundamental parameters. First, determine the application type. In industrial machinery, will the cable be stationary or will it be moving? Is the motion mainly flexing or is there torsional motion involved? Does the application call for both flexing and torsion? Different applications have specifically designed cables for that application.

Read the related article: What is flexible cabling and power cabling for industrial use? Technical summary

If there is bending or motion involved, specify the bend radius. This radius ultimately depends on the gauge of the wire and the kind of conductors used in the cable. The cable size includes the gauge of the wire, which is dependent on the current requirements as well, and the number of conductors needed by the application.

Generally speaking, finer conductor gauges can flex around smaller bend radii. Flat cables with PTFE jackets can have a larger bend radius than cables with silicone jacketing, given that each cable contains the same conductors.

Jacketing can include PVC and halogen-free to Neoprene, rubber, silicone and other materials.

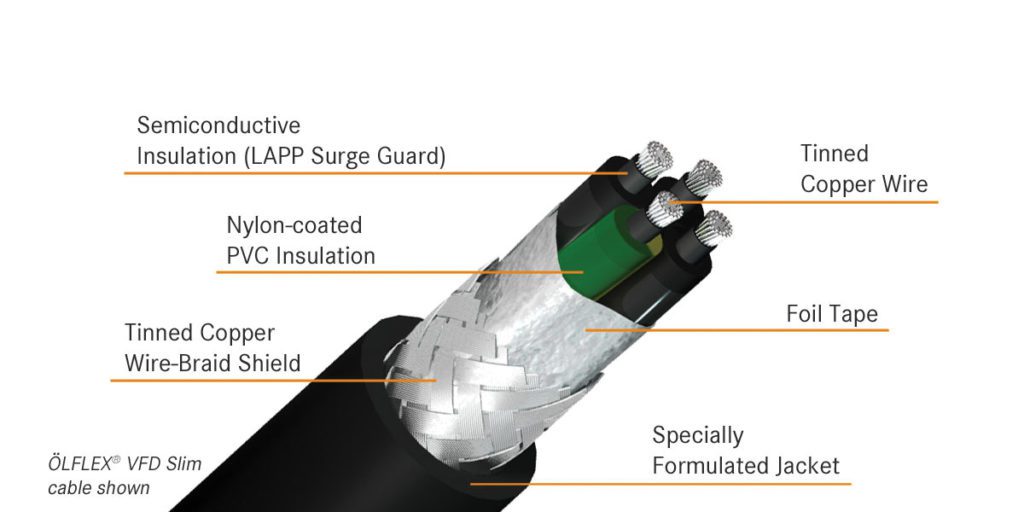

Next, consider the wiring itself … the number of conductors needed, the size of the conductors, and the operating voltage. Are there special insulation or jacket materials required?

For cabling used in flexing applications, two key factors are the wire conductors and cable jacket. With continuous flexing, conductors containing multiple strands of fine-gauge wire generally last the longest.

Are there any special shielding requirements? Don’t forget to check for any special approvals that may be required such as UL, CSA, CE, and so forth.

The environmental conditions in which the cable will operate are also relevant. For instance, what is the operating temperature for the application? Will the cables be in low-temperature (freezing and below freezing) or high-temperature environments? Will the cables need to be oil resistant? In this case, cables that provide minimal protection may be sufficient for low-level exposure …

… or the application may need cables that provide full immersion protection over many days.

Lastly, consider flame resistance. Cabling is available in myriad ratings to satisfy different codes and installation requirements.

Leave a Reply

You must be logged in to post a comment.