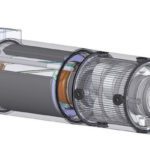

Miki Pulley’s Step-Flex couplings improve ball screw performance while solving resonance and vibration problems. The Step-Flex is an altogether new class of shaft coupling. The coupling design has a two-part elastomer element combination. This assembly dampens vibration caused by the actuator carrier when struggling to find its home position by making small adjustments in rapid sequence.

With this design, the hard (black) element is separated from the aluminum alloy hubs by a softer (green) elastomer disc. This combination maintains adequate torsional stiffness for precise positional accuracy while still allowing for minimal angular and parallel misalignment, and absorbing vibration. The power-transmitting element, consisting of different hardness layers, also achieves a reduction in counter force generated by misalignment. This can greatly reduce the load on the bearing – resulting in reduced heat load.

Another key feature is the electric and temperature isolation provided by the coupling’s elastomer element. This mitigates conductive heat transfer from motor to output shaft, important in rotary motion applications. Plus, it also halts stray voltage traveling on the shaft. Applications include automation of all types where ball screws are used including packaging systems, semiconductor assembly systems, laboratory automation and medical equipment.

Basic Step-Flex specifications include:

- 9 sizes available

- Torque: 531 in.-lb (60 Nm)

- Bore size range: 1/8 to 1.125 in. (3 to 30 mm)

To find out more and to see this coupling operate, visit www.mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.