Step-Flex, the new class of shaft couplings, eliminates resonance in stepper motor ball screw assemblies. Now with this video, system designers can see how this innovative two-part elastomer element combination coupling operates. Step-Flex Couplings are designed to “mechanically tune” the system for optimal performance when a stepper motor is used to drive a linear actuator.

Step-Flex, the new class of shaft couplings, eliminates resonance in stepper motor ball screw assemblies. Now with this video, system designers can see how this innovative two-part elastomer element combination coupling operates. Step-Flex Couplings are designed to “mechanically tune” the system for optimal performance when a stepper motor is used to drive a linear actuator.

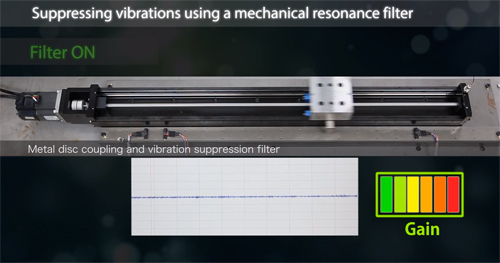

The Step-Flex features an innovative combination of HNBR (black) rubber element flanked by smaller, softer laminated (green) spacers. This unique design quickly dampens oscillations, thereby suppressing resonance. The coupling’s machined aluminum hubs also provides a low moment of inertia.

With the unique Step-Flex design, the hard (black) element is separated from the aluminum alloy hubs by a softer (green) elastomer. This maintains enough torsional stiffness for precise positional accuracy while still allowing for minimal angular and parallel misalignment, and absorbing vibration. The power-transmitting element, consisting of different hardness layers also achieves a reduction in counter force generated by misalignment. This can greatly reduce the load on the bearing – resulting in reduced heat load.

• 5 sizes available

• 5 sizes available

• Torque: 53 in-lbs. (6 Nm)

• Bore size range: 1/8” to 5/8” (3mm – 16mm)

Step-Flex applications include automation of all types where ball screws are used including packaging, semi-conductor assembly, laboratory automation and medical equipment.

Miki Pulley

www.mikkipulley-us.com

Leave a Reply

You must be logged in to post a comment.