Belts and pulleys are a mainstay of power transmission systems. Far from being obsolete, companies are innovating and offering smart solutions to contemporary motion system designs. Belt and pulley systems of all shapes and sizes are used in a range of applications from agricultural equipment to factory floor applications where they are an integral part of power transmission.

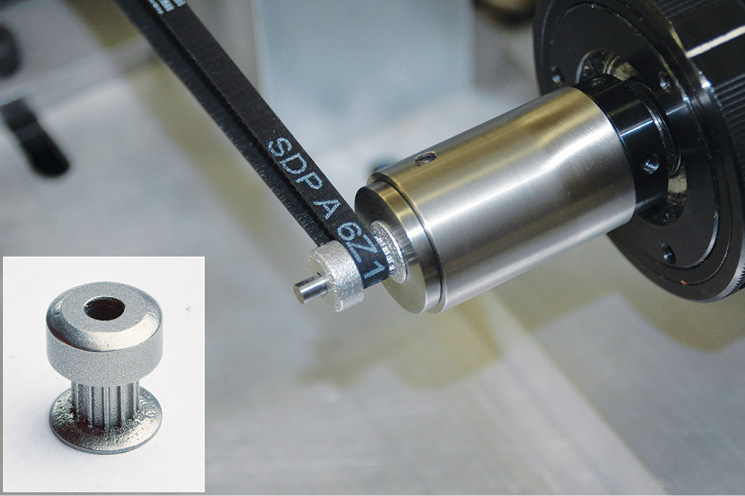

However, when asked about the importance of design simplicity, Cris Ioanitescu, Application Engineering Manager at SDP/SI, had an interesting take. “Contrary to popular belief, I don’t think that design should always be a race to simplicity,” says Ioanitescu. “Simplicity at times can dilute a product rather than distilling it. Especially in the miniature line of pulleys and sprockets, we follow the principal of making the product small but robust as well.”

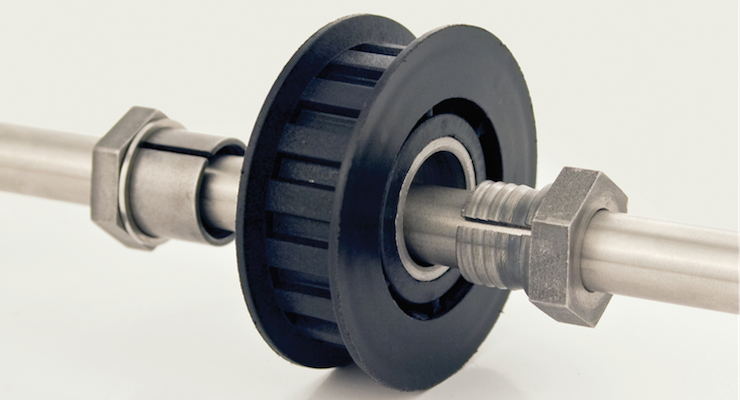

For example, Ioanitescu points out that narrow pulleys used for tight enclosures use shaft locks with complex shapes that can handle much higher torques than the initial clamp type or set screw type connection. To achieve the best performance they require careful designing of each component, including tight dimensional and geometrical tolerances.

Asked about what technology changes are influencing belt and pulley design, Ioanitescu points to the advent of 3D printing. “3D printing eliminates assembling components to produce a pulley,” notes Ioanitescu. “Subassemblies, such as a pulley, can be created as a one-piece construction in either metal or plastic.” Benefits for the end user include a fast turnaround time and no tooling charges. Customers can also submit their own models and have parts made directly from them.

Leave a Reply

You must be logged in to post a comment.