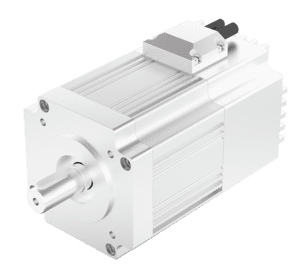

Delta Line’s mission is to provide the industry’s most agile, flexible, and personal service within sub-1kW motion systems. To achieve this, they invest and expand their product families to provide more flexibility for their customers. The newest addition to the company’s product portfolio is the IBS80, a brushless motor with integrated motion control. This motor expands the Delta Line family of motors, which includes both brushless DC motors and stepper motors.

The Delta Line IBS80 is a compact BLDC motor available in two models, with a rated torque range of 0.8-1.13 Nm. It is 80 mm2 by 120-130 mm in length and weighs just over 2 Kg. The IBS80 can be equipped with RS485 Modbus-RTU or CANopen fieldbuses and with an absolute single turn magnetic encoder or incremental magnetic encoder. This integrated motor contains system protections including over and under voltage, overcurrent, overheating, phase-to-phase, and ground shorts.

IBS80 Specifications at a Glance:

- Square face size (mm): 80 mm

- Length (mm): 120-130 mm

- Interface: Modbus-RTU, CANopen

- Rated Torque: 0.8 – 1.13 Nm

- Rated Current: 10 – 13.3A

- Rated Speed: 3210 rpm

- Operating Voltage: 24-48Vdc

- Weight: 2.1-2.2 kg

- Encoder: Magnetic incremental and absolute single turn

- Protection Class: IP54

Product designers recognize the space savings benefit from an onboard controller by eliminating the need for separate motor and controller locations. However, there are additional benefits to an integrated motor that are often overlooked. For example, by eliminating the power and electrical cables connecting the motor to the controller, the designer both saves space and decreases electrical noise. Cables are very often a design afterthought (and a significant headache for the engineer), so by eliminating the complexity of routing cables to the motor it keeps encoder signals free from electromagnetic interference (and makes the engineer’s job easier).

An integrated motor such as the IBS80 also contributes to a streamlined design and integration process. Since the drive and the motor are already configured, it is ready to go right out of the box. Reduced integration time directly correlates to reduced product development time. Additionally, the parameters are preconfigured for the best motor performance, leading to improved system efficiency. We know through our own experience in applications such as healthcare, intralogistics, security, and robotics that system efficiency has become a priority in machine design. All of these factors combined means that our customers see a 20%-40% reduction in their cost with the integrated motor approach.

Delta Line provides a variety of integrated brushless DC and stepper motors. For example:

| IBS42 | IBS57 | IBS80 | IBI80-IP65 | ISI57-IP65 | ISI60-IP65 | |

| Motor Type | BLDC | BLDC | BLDC | BLDC | Stepper | Stepper |

| Torque Range (Nm) | 0.062-.25 | 0.055-0.42 | 0.8 – 1.13 | 0.9-1.13 | 0.55-1.89 | 1.1-3.1 |

Leave a Reply

You must be logged in to post a comment.