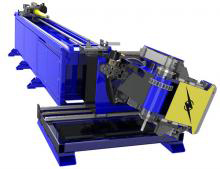

Unison (www.unisonltd.com) has introduced a machine that features a rotating tool head that enables left and right-hand bending in one fast and continuous automatic cycle. Known as the Unison Breeze-Revolution, the new machine optimizes both the ability to increase production throughput as well as to fabricate extremely difficult tubular shapes.

The new electric tube bender is designed with two multiple-tool heads fitted on the rotating frame’s opposite sides. After bending utilizing one or more of its tools, the head retracts while a combination of rotational and transverse movement prepares the left-hand head for the next bending operations.

Aside from offering various innovations that enhances the versatility and precision of the bending capability, the new machine also comes with a movable platen and long pressure die that enables it to create complex shapes that includes a 180 degree bend performed in a single rapid and continuous operation.

The all-electric, servomotor-controlled architecture of the machine provides a comprehensive programmability across the part fabrication cycle. The tube bending dies’ forces and position can be accurately controlled to generate the highest quality and accuracy of shape fabrication and end result.

The all-electric, servomotor-controlled architecture of the machine provides a comprehensive programmability across the part fabrication cycle. The tube bending dies’ forces and position can be accurately controlled to generate the highest quality and accuracy of shape fabrication and end result.

At the center of the Unison Breeze-Revolution is a motion system and real-time machine anchored on the deterministic Ethernet-compatible Powerlink protocol. The servomotor drives are connected to the control bending operations by a 100 Mbits/second network. The network’s speed allows it to rapidly coordinate the various movements of the servomotor axes utilized during bending to effectively enhance the speed of bending.

Unison can also provide the new left-hand/right-hand rotating head architecture on electric tube bending machines that can handle tubing with a maximum diameter of 180 mm (7 inches).

Leave a Reply

You must be logged in to post a comment.