The winners of the 2020 LEAP Awards (Leadership in Engineering Achievement Program) were announced yesterday in a digital ceremony, with products across 12 categories, including Industrial Automation.

Critical to LEAP’s success is the involvement of the engineering community. No one at WTWH Media was involved in selecting the winners. Instead, our editorial team assembled a top-notch independent judging panel, comprised of a cross-section of OEM design engineers and academics — 14 professionals in total. This judging team was solely responsible for the final results.

In the Industrial Automation category, the winning submissions for this year are:

Gold

Universal Robots

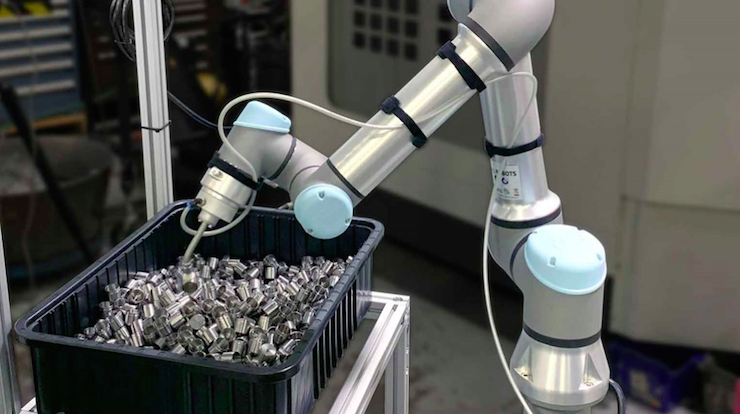

ActiNav – Autonomous Bin Picking for Machine Tending

ActiNav is a pioneering hardware/software kit that synchronously handles vision processing, collision-free motion planning and autonomous control. ActiNav can easily be operated by people with no background in machine vision or robot programming.

ActiNav combines powerful real-time autonomous motion control, collaborative robotics, 3D vision and sensor systems in one user-friendly kit. The system can autonomously insert parts into CNC or processing machines, such as drilling, deburring, welding, trimming or tapping. Its high-resolution 3D sensor and CAD matching enables high-accuracy picks. Meanwhile, ActiNav’s Autonomous Motion Module works out how to pick and place the part, precisely. Autonomous motion control enables ActiNav to operate inside deep bins that hold more parts; something that is beyond the capabilities of most standalone bin picking vision systems.

It’s also the first system to solve three longstanding challenges in bin picking: picking up unstructured (randomly positioned/oriented) objects, maintaining a consistent picking orientation and precise placement.

ActiNav transforms traditional ‘pick & drop’ automation processes into accurate pick and part-oriented placements. Most importantly, ActiNav eliminates the complexity, risk and costs associated with traditional bin picking automation, opening up exciting new robot possibilities for smaller manufacturers.

The judges commented: “This invention is clearly one of the best designs that has come along in a long time. Applications for picking various types of parts and placing the parts without a secondary orientation has been a battle with prior art.”

Silver

FUTEK Advanced Sensor Technology, Inc.

Digitally Configurable Analog Voltage Amplifier

The IAA105 Digitally Configurable Analog Voltage Amplifier amplifies and scales low amplitude and/or high impedance analog voltage signals to levels that can be directly used by a system block, such as a PLC, while minimizing gain and offset errors.

Nearly all industrial automation applications require a reliable feedback loop with fast response time, high accuracy, and repeatability. To support this, the IAA105 has been designed to accept a variety of signal ranges to amplify, condition, and provide noise immunity. Some common applications include wire tension measurement, hydraulic/pneumatic press force, and mass flow meters.

Most currently available devices are not digitally configurable. This leads to two issues—human error and low resolution. With the capability of digital calibration, this device can calibrate at high resolution and eliminates human error entirely. And because the device needed human interaction to configure, it wasn’t possible to use it in applications where space and form factor were small and difficult to access. With digital configuration, this device is now capable of being located virtually anywhere within a system and it can be calibrated and configured easily.

Bronze

Microchip Technology Inc.

Microchip Smart Embedded Vision Initiative

The Smart Embedded Vision initiative provides a suite of field programmable gate arrays (FPGA) offerings that provide hardware and software developers with tools, intellectual property (IP) cores, and boards for meeting the thermally constrained and small-form-factor requirements of edge applications across the industrial, medical, broadcast, automotive, aerospace and defense markets.

As compute-intensive, vision-based systems are increasingly integrated at the network edge, FPGAs have quickly become a preferred flexible platform for next-generation designs. In addition to requiring high bandwidth processing capabilities, these intelligent systems are deployed in small form factors with tight thermal and power constraints.

The initiative is driven by Microchip’s PolarFire FPGAs which offer 30-50 percent lower total power than competing mid-range FPGAs. With family members ranging from 100K to 500K logic elements (LEs), PolarFire FPGAs provide five to 10 times lower static power, making them ideal for a new range of compute-intensive edge devices, including those deployed in thermally- and power-constrained environments.

For example, in applications such as a smart camera, PolarFire FPGAs can integrate the image signal pipeline which includes the sensor interface, DDR controller, image signal processing (ISP) IP and network interfaces, all while integrating the machine learning inference.

Honorable Mentions

The judges awarded several honorable mentions in the Industrial Automation category this year. Among them were:

Cognex Corporation

In-Sight D900

The In-Sight D900 is a smart camera powered by In-Sight ViDi software designed to run deep learning applications. This embedded solution helps factory automation designers solve challenging industrial OCR, assembly verification, and random defect detection applications anywhere on the line that have gone uninspected because they’re often too difficult to program with traditional, rule-based machine vision tools.

OnRobot

Screwdriver

OnRobot’s Screwdriver is an automated screwdriving system that’s compatible with all leading robot brands. End-users simply put screws in the supplied feeder (or use 3rd party feeders), attach Screwdriver to their robot and enter the screw length and torque requirements through an intuitive interface. Using its built-in force/torque sensing and linear motion control, Screwdriver automatically calculates the speed and force required to enable consistent, accurate screwdriving. It also automatically recognizes screw presence and obstructions. Its ability to detect incorrect screw lengths reduces scrap and improves quality.

YXLON International

YXLON UX20 – The Easy Inspection

Yxlon designed the UX20 system from the ground up for fast and easy x-ray inspection of parts. The Geminy user interface enables easy inspection, both for 2D and 3D. Plus, efficient workflows with automation, wizards and presets help guide the user. With ScanExtend, wizards help guide set up of various scan-field extensions for scanning even the largest parts in the system. The optimized image chain with x-ray tube, detector and image processing software provide benchmark image quality, the basis for best inspection results.

Leave a Reply

You must be logged in to post a comment.