Proximity sensors are commonly used in many automation applications. They’re used to sense the presence of objects and don’t require physical contact with the target or object being sensed, which is why they’re often referred to as non-contact sensors. Common proximity sensor types include photoelectric, capacitive, and inductive sensors.

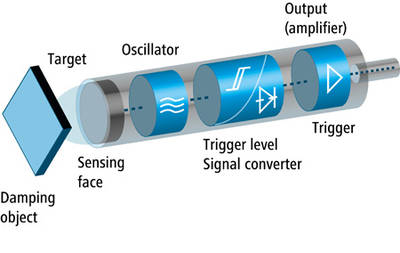

Inductive sensors operate on the basis of Faraday’s Law. One way to state Faraday’s Law is that a change in magnetic flux in a coil of wire will induce a voltage in a nearby coil. This is applied in inductive proximity sensors in the following way: The sensor itself contains an oscillator circuit and a coil from which an electromagnetic field radiates out and induces eddy currents in any nearby metallic objects. The eddy currents have the effect of attenuating the oscillations from the amplifier. This reduction in oscillations is registered as the presence of a metallic object.

Because only metallic objects have inductive properties, inductive sensors can’t be used to detect plastic or cardboard or other non-metallic objects. However, different metals have different inductive properties and the type of metal being sensed will influence the sensing distance. For instance, ferromagnetic materials like steel generally have the longest sensing distance, while non-ferrous metals such as aluminum or copper have much shorter sensing distances. In general, inductive proximity sensors are well suited to shorter-range applications as the inductive effect wears off with growing distance between the sensor and object to be detected.

Inductive proximity sensors hold up well in dirty environments where contaminants don’t interfere with the sensor’s ability to detect metallic objects. For example, they’re resistant to dirt, dust, and smoke in the environment between the sensor and the object to be detected. As for build-up of contaminants on the sensor face such as dirt and dust, oil, grease or soot, these don’t effect the inductive sensing. However, metallic contaminants such as metal chips in machining applications will impact sensor operation. The key is to be sure to understand what type of contaminants an application contains in order to select the correct type of sensor that can handle them and operate effectively.

Leave a Reply

You must be logged in to post a comment.