Motion is present in almost all industrial automation systems. Stopping or changing the direction of that motion releases kinetic energy, which can cause shock and vibration to occur. Any sudden shock in a system can cause immediate damage to the overall machine and the components it may be manufacturing or processing. And consistent vibration inputs can cause damaging fatigue over time.

This is why it’s necessary to decelerate a system smoothly through the use of shock and vibration absorbers.

Based on the type of inputs present in the application, vibration and shock attenuation components can be comprised of shock absorbers, linear dampers, wire rope or spring isolators, elastomeric isolators, air springs, or structural damping treatments. These devices help manufacturers reduce equipment downtime and costly cycle time limitations.

These products can be used in a broad range of applications, from the rate control mechanisms that slow the motion of the overhead luggage bin or seat recline on commercial aircraft, to the isolators which keep GPS systems from losing signal or becoming damaged on farm and construction equipment as they harvest crops or pave roadways.

Most shock absorbers achieve their damping characteristics through the use of hydraulic fluids. The fluid is pushed by a piston and rod through small orifice holes to create damping, and this action compresses some type of gas. This in turn creates a spring force to return the rod back to its starting position when the load is removed.

Shock absorbers and dampers are generally made of high-strength steel to handle the pressures from the internal hydraulic forces. Elastomeric seals prevent the fluid from leaking out of the cylinder, and special plating and coatings keep the units protected from harsh operating environments.

Recent and ongoing developments in sealing technologies and in the internal designs of shock absorbers and dampers have allowed for longer service life and more compact designs. Ongoing research in the field of noise attenuation (high frequency, low amplitude vibration) has led to an increased effectiveness in noise reduction technologies.

A unique application for these types of hydraulic damping devices has come with the increased awareness for seismic and environmental protection of our infrastructure (buildings and bridges, for example). By adding damping to these critical structures, energy is absorbed by the hydraulic devices instead of damaging the structure.

Vibration isolation products rely generally on mechanical designs to achieve their isolation characteristics. A spring function provides support for the mounted equipment, while decoupling it from the vibration source. Friction and elastomeric material properties give the isolators their damping characteristics.

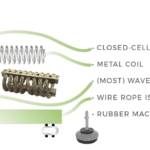

Isolators can be made from a variety of materials. Wire rope and spring isolators can be made from carbon steel, stainless steel or aluminum. Elastomeric isolators generally have metallic components that function as mounting brackets, separated by an elastomeric material that provides the stiffness and damping desired. Common elastomeric compounds include natural rubber, neoprene and silicone; however, a vast selection of compounds and compound blends can be used to achieve different characteristics specific to the application.

Air springs are comprised of metallic end fittings coupled by a composite elastomeric-based bladder that contains the compressed air used to provide isolation. These single-acting designs are comprised of a pressurized bladder and two end plates. As air is directed into the air bladders, they are expanded linearly.

All of these reusable designs are self-contained, offering a number of advantages over any other technology that may require outside componentry. For example, hydraulic systems may require plumbing while electrical systems may require wiring and power.

Energy or power dissipation is key when selecting a damper or shock-absorbing device. The size and characteristics of the device are based on these inputs, so it is generally the first consideration to make.

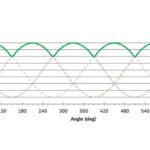

Dynamic spring rate and damping are the two biggest considerations when selecting an isolator. These characteristics will define the natural frequency (sometimes referred to as resonant frequency) of the isolation system and are important in achieving the target performance.

Leave a Reply

You must be logged in to post a comment.