Controllers that are PC-based are typically programmed via a Windows computer and used to communicate with, monitor, and control industrial machines and equipment. As the name implies, being PC-based means that the PC monitor is the main graphical user interface (GUI).

One advantage of PC-based controllers is their GUI. PC-based controllers are programmed via a PC that, using a monitor, is a better GUI than what a typical PLC or standalone controller offers. Usually these latter controllers have either an LCD display combined with a small keypad or maybe a touchscreen display, which can make viewing data as well as programming the controller difficult.

Another advantage of PC-based controllers is that the PC platform is familiar and so there is less of a learning curve for commissioning and programming and setup. A big reason why it’s so familiar is the PC GUI which makes it much easier to program and work with the system than other types of controllers that may have GUIs that are not as intuitive or user friendly. PC-based controllers are also easily scalable for expanding and changing motion control requirements.

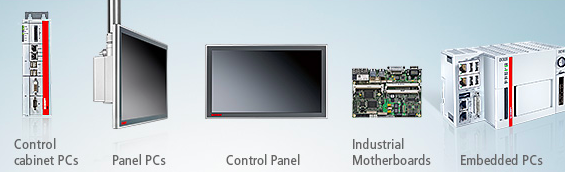

A common type of PC-based controller is the industrial PC. They run on processors like other PCs but are built with more rugged components designed to withstand the harsh conditions of industrial environments. These conditions can include shock and vibration, noise and dust, as well as exposure to harsh chemicals and extreme variations in temperature and humidity.

Leave a Reply

You must be logged in to post a comment.