The unpredictable global economy has derailed formally reliable supply chains, causing extra stress on both established products and systems currently in development. Prior to 2018, many engineers selected motors and motion control options based on what they used in the previous machine design. Today, engineers have the burden of factoring in product availability and price on top of system performance. This responsibility can be daunting. No matter if your biggest concern is system price, performance, or the details of integration, Delta Line is here to help.

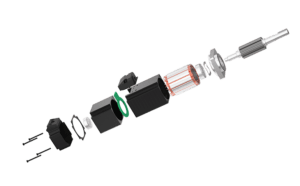

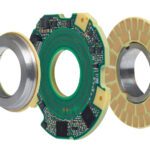

Delta Line’s mission is to provide the industry’s most agile, flexible, and personal service-in-motion systems. This is why the company supports a robust range of products that includes motors, controllers, integrated motors, linear actuators, gearboxes, encoders, and more. Delta Line has been in the motion control industry for more than 40 years and has first-hand experience garnered from its product portfolio, including the popular brushless slotted motor line that has been in applications for over two decades. It recently added a servo motor family that includes low and medium-voltage motors. It knows that historically, “servo” was associated with only high-cost product options. However, its customers have found that its servo motors, like its other motors, are a price-attractive option. Delta Line’s application engineers focus on performance per Euro to match customers up with a suitable motion solution. Customers seek out Delta Line’s competency for both new applications and existing applications where the availability or cost of current systems has become prohibitive.

It happens more times than anyone wants to admit – you simply need more performance out of one (or more) axis. Frequently, stepper motors are being pushed to where servo motors are the better option. Managing the technology change from stepper to servo appears overwhelming at the surface, but with Delta Line’s low voltage optimized servo motor options, Delta Line’s engineers can help you manage the jump. They can help you select the right servo motor to replace your stepper motor. The company also provides a wide range of servo controller options to complement its motors including DC, AC, programmable, multi-axis drives, and integrated motor controllers. The Delta Line drives are also available with EtherCAT, Modbus, CANopen, and Profinet. The company’s application engineers also assist with other important details including connectors, cables, feedback devices, and more. Whether you are looking for a simple system to replace a stepper axis or are ready to take on a more advanced approach, it has the motion and drive pairing for you.

Delta Line’s engineers have seen countless applications where an existing axis needs to make a change: from simple winding adjustments to new motor types to complete system redesigns. Instead of struggling through the change curve yourself, let the company’s application engineers assist you. They know your time is valuable, which is why they have CAD drawings and other support documents available. Engage their technical support as you need it — they provide a wide range of application support, including firmware, software, and mechanical compatibility. Since its portfolio of products is so robust, it can support you with a variety of different products to meet your performance requirements

Leave a Reply

You must be logged in to post a comment.