By Leslie Langnau • Compression springs are typically used to resist linear compressing forces (such as a push force) where space is limited, where uniform bearing pressures are required, or to reduce buckling.

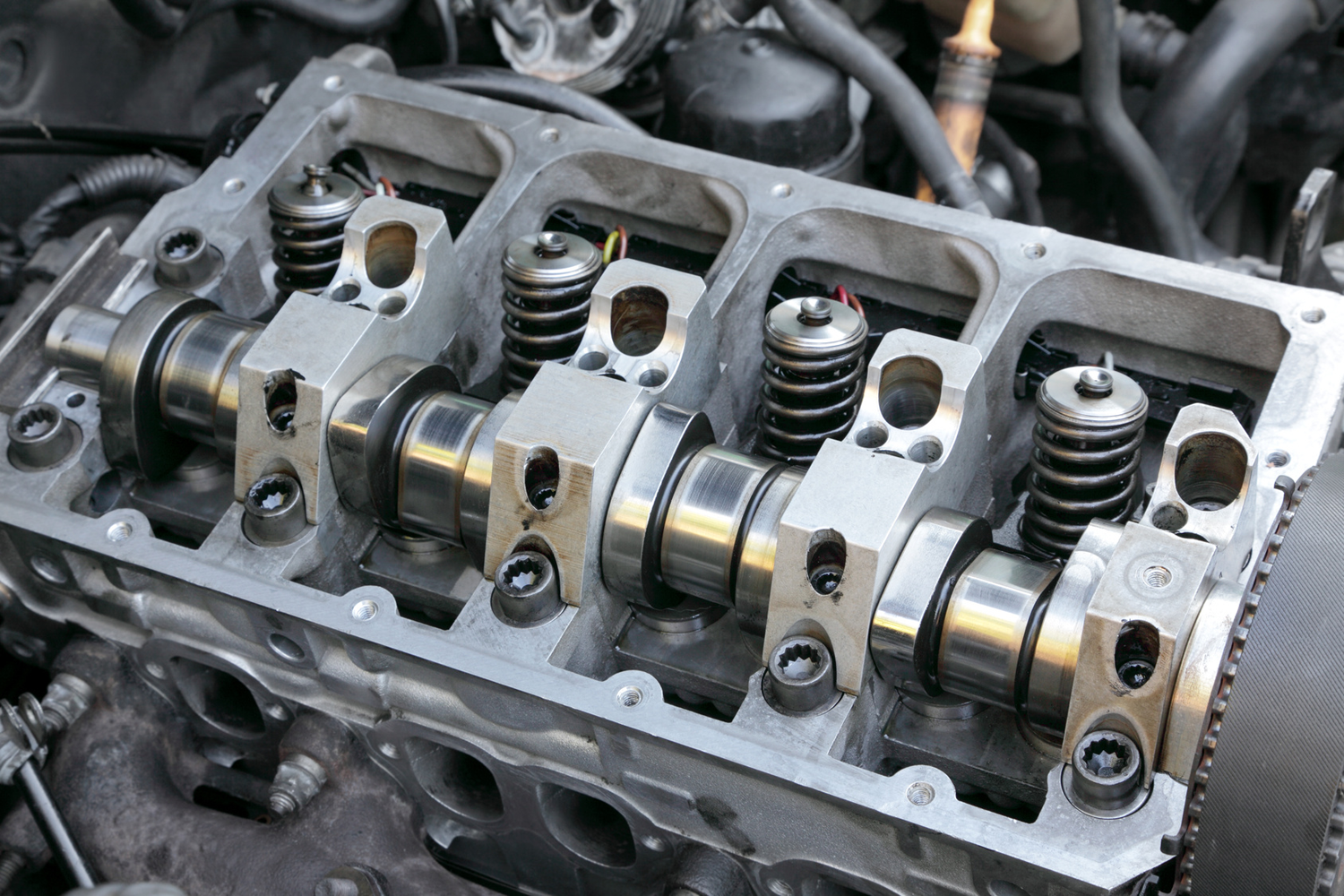

Thus, they are ubiquitous motion components. In the automotive industry, they are common in seats, pedals, transmission springs and windshield wipers. More after the jump.

Building automation uses compression springs for industrial doors, fasteners and dampers. In electric-distribution applications, they are indispensable for the function of contact switches and other electromechanical components.

Medical uses for compression springs also abound—in simple mechanical equipment, such as beds, to those in advanced actuators for precision medical devices. In consumer devices, they are found in major appliances, lawn mowers, cell phones and so on.

Leave a Reply

You must be logged in to post a comment.