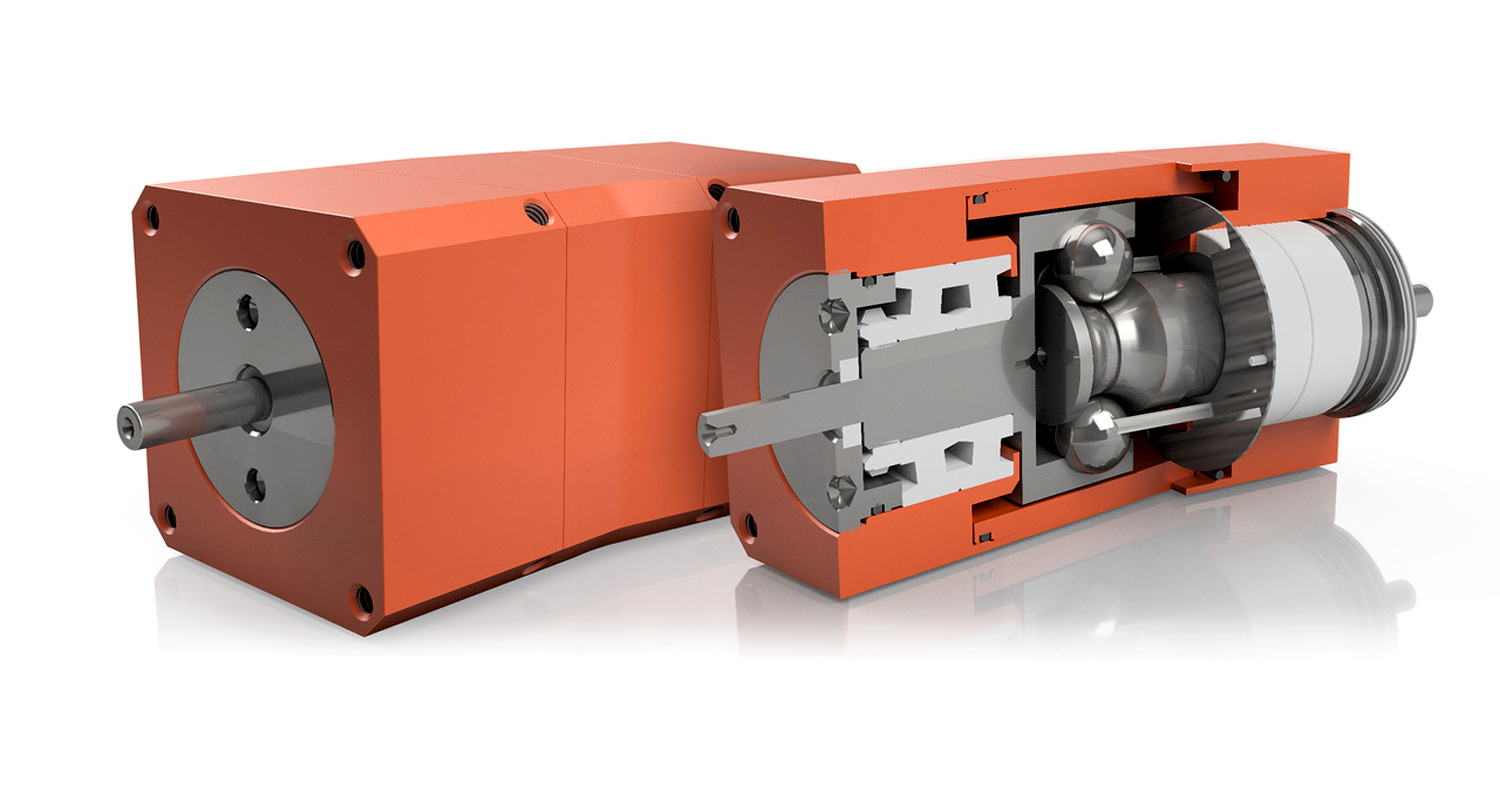

Rolling Motion Industries (RMI) has released two high-efficiency traction drives — the MAR-17-1-2.1 Traction Drive and the MAR-23-1-2.1 Traction Drive. These are 1-Way traction drives with only six moving parts and use an engineered traction fluid with a coefficient of friction of just 0.1 to 0.12. These traction drives typically last three times longer than conventional gearboxes and with no metal to metal contact these high efficiency drives generate up to 72% less heat after 24 hours of continuous operation, Additionally they create up to 38% lower dB at 3000 rpm (less than a home refrigerator) than conventional gearboxes. Even though there’s no metal to metal contact there’s no slippage or lost motion between the input and output shafts.

The MAR17-1-2.1 Traction Drive is designed for speeds to 3,600 rpm with 10 to 20 in/lb of torque, and the MAR-23-1-2.1 Traction Drive is rated for 3,600 rpm with 20 to 30 in/lb of torque. Operating at temperatures that are lower than a motor’s, with low vibration, and no torque losses from 10 to 3,000 rpm, these traction drives permit a motor to operate at peak efficiency. Applications for these 1-Way traction drives which can operate in explosive environments (ie. zone 1 and 21) include: Pumps, blowers, fans, turbo and super chargers, conveyers, HVAC systems, medical applications, and other power transmission and motion applications.

These revolutionary drives are available with an optional overriding clutch. Incorporating standard NEMA mounting dimensions, these drives can be easily integrated into new and existing applications.

In 1993 John Pawloski and his brother Ray took over the family business, Jewelers Machinist Co. They realized they needed to switch from outdated conventional thread grinders to CNC thread grinders. As a result, Jewelers Machinist Co is a source of some of the most complex thread grinding in the industry. The concept for the RMI traction drive came from John in 2007. Working in that high precision industry aided John in the development of the RMI Traction Drive.

In the years that followed, the design of the individual components and formula of the engineered traction fluid were finalized, testing was completed, a patent granted, and production begun. The RMI Traction Drive is one of the most efficient ways to transmit power from one point to another. Using rolling motion, RMI is able to transfer power at various ratios with minimal energy loss. Tested against V-belt, direct drive, chain, and gearbox setups, RMI Traction Drives offer energy saving benefits through true efficiency rating percentages up to 98%. The high efficiency of the traction drive allows electric motors to run at their peak efficiency ranges.

There are many applications where it can be used from automotive to industrial to medical. The RMI traction drive can be used in the electric vehicle market and precision applications. Offering benefits such as low backlash and no back driving, it set a new standard for high efficiency.

For more information, call (860)846-0530, email info@RMIDrive.com, or visit RMIDrive.com.

Leave a Reply

You must be logged in to post a comment.