PARKPLUS is a designer and builder of both mechanical and fully automated high-density parking setups for North America. The manufacturer recently developed an advanced parking system based on free-roaming battery-operated AGVs with omnidirectional maneuverability.

Drivers pull their cars into a vehicle-receiving area and onto a large waiting platform called a tray. Then an AGV goes underneath the tray to lift it from below, and transport it and the vehicle to storage garage. Traffic-management software, lasers and machine vision, and markers give the AGVs self-guidance functionality for automated storage and retrieval of vehicles on trays. PARKPLUS system install in new or existing multi-level parking structures.

The challenge here is that many such garages have low ceilings to maximize vertical space. So the AGVs that serve the PARKPLUS setup must be quite flat … but still powerful enough to transport a vehicle around a garage. These conflicting design objectives put severe limitations on the AGV design, especially for the drivetrain.

In fact, the drivetrain consists of two motors and gearboxes that mount directly into the omnidirectional wheels. PARKPLUS partnered with GAM Enterprises — manufacturer of precision gear reducers, servo couplings, linear-mounting kits, and other automation products — to develop a compact gearbox setup to handle the demanding performance requirements of transporting vehicles.

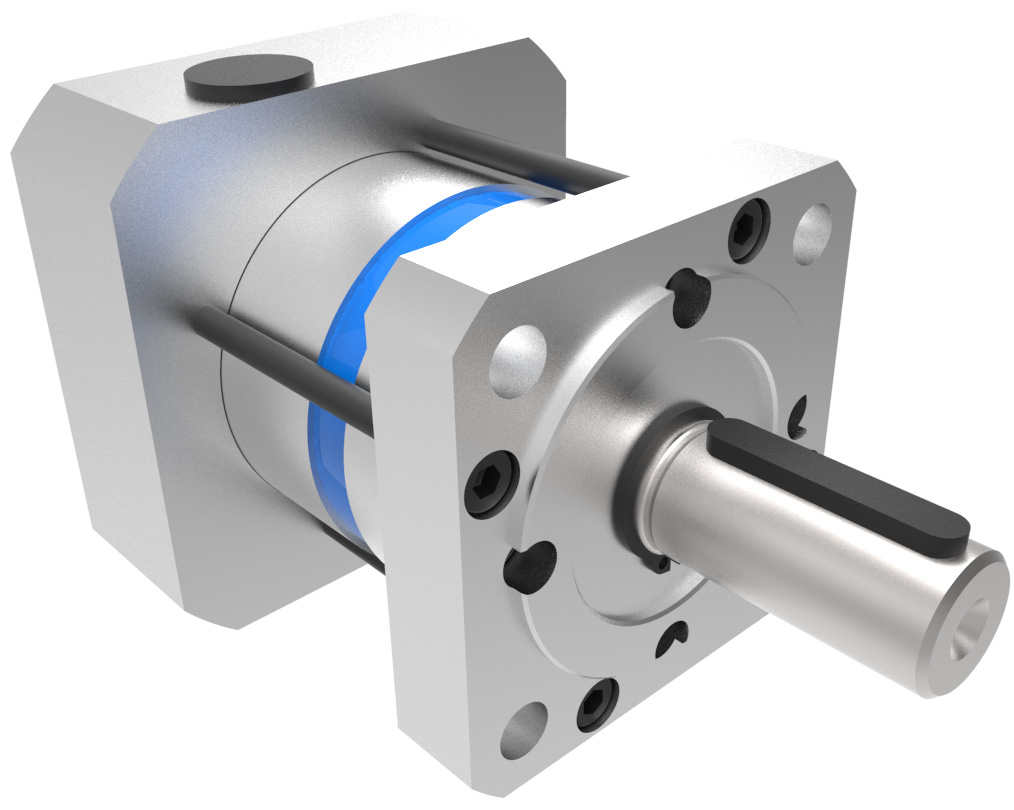

Given the predefined space limitations, GAM selected a 64-mm frame size EPL gearbox able to fit into the assembly properly and accommodate the basic torque requirements. The standard EPL series is extremely reliable with hardened and ground straight-cut gears and heavy-duty angular contact bearings for a 30,000-hour life rating. To absorb the shock and reversing loads the AGV encounters when moving through the parking structures, GAM engineers designed a modified gearbox solution with an output housing and shaft that’s more robust than other offerings. Plus they added tie rods for additional reinforcement. The EPL gearbox setup also satisfies a 12x safety factor specified by PARKPLUS.

“We worked with GAM because of the flexibility their engineering team offered given the stringent requirements placed on them as well as the willingness to provide the exact gearbox to suit the AGVs,” said Andreas Wastel, V.P. and Chief Engineer of PARKPLUS.

It’s largely because of the GAM gearboxes that the AGVs are as space efficient as they are, he added.

The PARKPLUS AGV system has been in operation for more than two years in several locations and has been performing to specification.

For more information on GAM and the EPL series inline gearbox, visit gamweb.com.

Leave a Reply

You must be logged in to post a comment.