In recent years, industrial electronics suppliers have supported efforts to simplify control-cabinet setup with Actuator-Sensor or AS-Interface connections. These solutions can often replace messes of wires with clean and uncluttered cabling. Well-established in Europe, the U.S. automation industry (especially for packaging) is now adopting AS-Interface for its cost-effective high-speed performance. That’s especially true for actuators and sensors at the peripheries of equipment needing continuous monitoring to minimize downtime should errors occur.

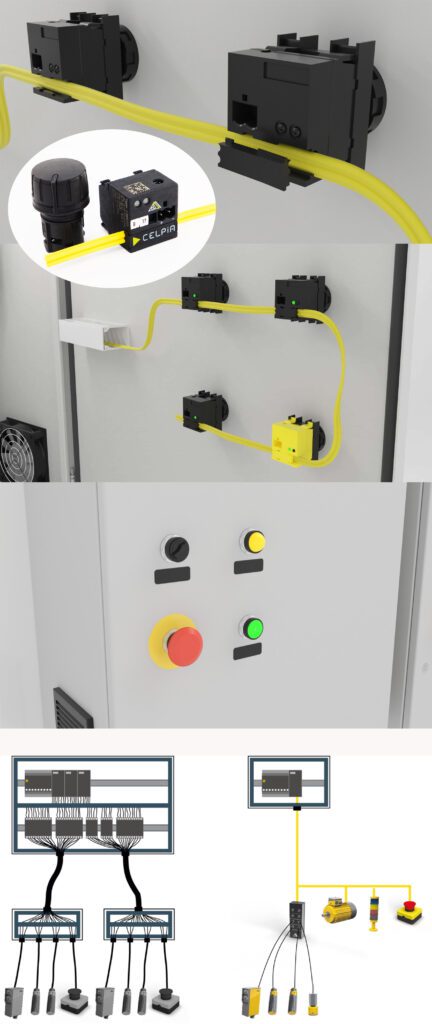

Consolidating wiring: Every actuator, sensor, and safety element in a given piece of equipment needs its own wired connection. Here, AS-Interface two-conductor cables eliminate the need for separate power and data wire. That in turn trims installation time and cost as compared to traditional installations. Some AS-Interface products even allow tool-free wiring; these have a wedge-and-pierce design to let junctions pierce (and electrically join) AS-Interface wire conductor strands in one simple step.

Simplifying troubleshooting: Faults in traditionally wired control cabinets are famously difficult to find … but personnel must quickly locate and fix errors to minimize downtime.

In contrast, devices connected via AS-Interface can leverage the data channel to self-communicate errors. In addition, some cabinet modules are capable of displaying six color signals (to indicate fault details) for eight parameters — all using ASi-5 diagnostics and monitoring. Safety features such as emergency stops can easily be added, as the technology supports switches and pushbuttons of any brand.

Celpia | celpia.com

Leave a Reply

You must be logged in to post a comment.