Advances have improved the performance of belts over the last few years. That’s good news for the $6 billion belt industry, expected to grow 7% this year, according to industry-research company IBISWorld. The increase is mostly thanks to an uptick in automotive, industrial and mining applications, with U.S. oil and gas exploration and production expanding the range of belt uses most.

One new trend in technology is belts with carbon tensile members. “This is because certain heavy-duty timing belts with carbon tensile members can transmit up to five times more output than conventional timing belts of the same width,” said Regina Arning, head of industrial business at ContiTech Power Transmission Group.

The reverse also applies, so that if a design only needs a given output, the timing belt only needs to be one-fifth the width. The individual belt is cheaper, plus there are overall machine-cost savings in applications that use toothed pulleys, as other machine geometries can also be narrower.

The trend towards more efficient and powerful belt drives (mostly in the form of heavy-duty timing belts) is for machine and plant engineering, as well as agricultural, wood processing, printing, and packaging machinery, according to Arning.

Case in point: UNTHA shredding technology GmbH runs waste and wood-shredding plants that make extensive use of belt drives. “In some shredders, our belts drive a secondary shredder used to turn waste into fuel. They transmit driving force from the drive motor to the drum with a rotational speed of 10 m/sec at very high force peaks. Throughput can be as high as 15 metric tons of waste per hour. So although the secondary shredder processes material that’s pre-shredded, the belts must withstand heavy loads,” said Arning.

Consider another new application making use of carbon-fiber-reinforced belts: More eBikes and pedelecs are going to chain-free designs with a drive consisting of two lightweight metal sprockets and a high-strength belt embedded with carbon fiber cords.

Made by Gates Corp., the belt drives already go into Canyon, Stevens, Grace, Biomega, Ibis, Idworx, Flitzbike, Nicolai, Schindelhauer, Overlap, Dvoika, Faraday and Electrolyte bike brands.

“The electric-bike category is a growth segment because our system is a smooth and clean alternative to chains,” said Todd Sellden, director of Gates Carbon Drive Systems.

Taking cleanliness a step further is metal-tape belt drives. These are particularly suitable for industrial plant applications.

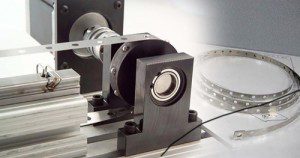

Metal drive tapes generate no particulate, operate without lubrication, and don’t stretch, so they maintain a set precision indefinitely.

“Stainless-steel drive tapes for linear positioning applications usually have end attachments for strong terminations,” said Ivan Amaya of Belt Technologies. “Then we can add perforations that engage specialized timing pulleys for high positional accuracy.”

Another innovation in belt applications is the proliferation of design tools over the last decade. Online calculators and automated customization options abound. For example, Gates offers a sonic tensioning app for iPhones and Androids that uses the phones’ microphones to let installers tune belt tension by plucking them. On another front, ContiTech has a free software suite consisting of a Transmission Designer (to let engineers setup two-disc drives) and Drive Alive (to let them setup more complicated drives, including those with tensioning systems). Results include lifecycle and tension values.

— Lisa Eitel, Motion Editor | @DW_LisaEitel

Stay tuned, as I’m assembling a piece on belt and conveyor drives for the April Power Transmission special as well.