When it comes to exploring our disc-shaped spiral galaxy, astronomers have a fundamental problem: Earth is located on the disc of the Milky Way, which obstructs the view of the galaxy’s center (and its other side) with countless stars.

When it comes to exploring our disc-shaped spiral galaxy, astronomers have a fundamental problem: Earth is located on the disc of the Milky Way, which obstructs the view of the galaxy’s center (and its other side) with countless stars.

So determining where on the disc other celestial bodies are located is difficult to impossible from Earth. It’s also hard to study the center of the galaxy, where countless stars and gas clouds cluster around what’s believed to be a black hole.

But a major astronomy project aims to change that. Eight institutes from several countries (commissioned by the European Southern Observatory or ESO) jointly operate the world’s most powerful telescopes in the Chilean Atacama Desert in coordinated efforts to better understand the Milky Way.

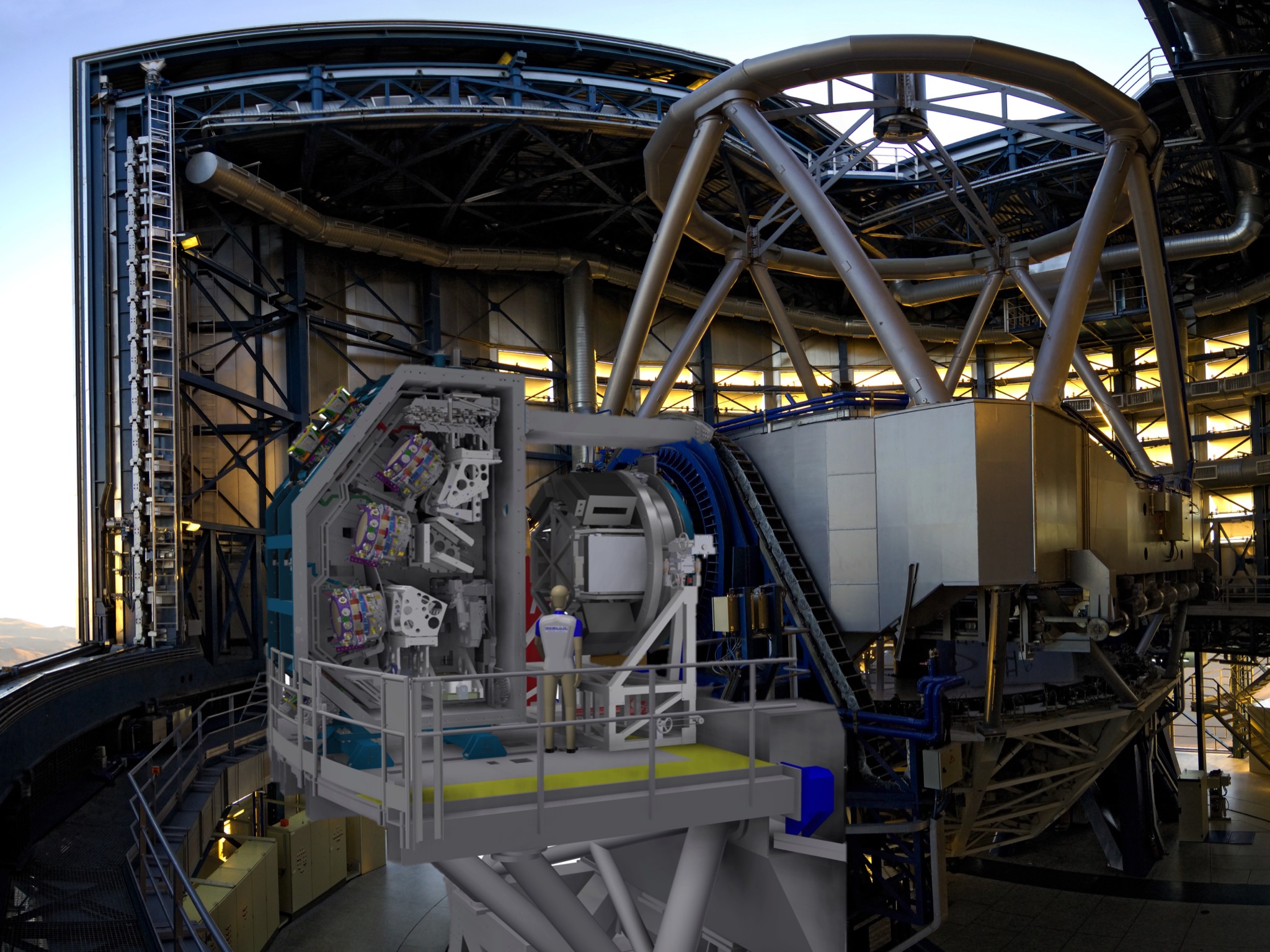

The site includes the Very Large Telescope (VLT) at the Paranal Observatory having a mirror diameter of 8.2 meters.

One goal of this Multi-Object Optical and Near-infrared Spectrograph (MOONS) project — coordinated by the U.K. Astronomy Technology Centre (UK ATC) in Edinburgh — is to equip the VLT with a new instrument to capture more optical signals from space. The instrument in question is a spectrograph capable of simultaneously imaging many cosmic objects in the visible and infrared parts of the electromagnetic spectrum.

“With a high-quality photo camera one can change the lens. But with astronomy telescopes, it’s the opposite … the VLT has an outstanding lens, and we will simply replace the current camera with the MOONS,” explains UK ATC scientist Dr. William Taylor.

With its new technology, MOONS enables new possibilities for observing space, even though it doesn’t produce large-sized images in the traditional sense. Instead, it captures minute details.

This is how it works: As with previous designs, the huge lens and mirror of the VLT are pointed at the part of space that is to be observed. But in the MOONS VLT, the ends of 1,001 optical fibers align to individual objects. Instead of capturing the entire selected area like a camera, the new instrument focuses the fibers on certain points in the Universe.

The points are photographed and their light is separated by prisms into the individual components — in other words, different wavelengths.

“Scientifically speaking, this method yields much more information than an image,” explains Taylor. “For example, we can learn about the chemical composition of the object. Furthermore, this allows us to calculate its dynamics — in other words, the velocity and direction of movement. Because MOONS captures the near-infrared spectrum, we can precisely analyze the redshift to which light from distant objects is subject on its way to us.”

When a star moves away from Earth, the wavelength of its light becomes longer. This is how part of the visible light shifts to the invisible infrared range — which is still close to the visible spectrum.

Prior technology allowed for a maximum of about one hundred objects to be observed individually, and only in the range of visible light. MOONS not only multiplies this number by ten, but the depth of information also increases manifold. Within the Milky Way, this will enable us to look much more precisely between the trees and get a much clearer picture of the entire proverbial forest.

“One of the objectives of the project is to create a 3D map of the Milky Way to allow a sort of GPS navigation through the galaxy. The MOONS design’s unprecedented resolution also enables us to look very far … thus also very far back in time. With it, we’ll be able to approximate the Big Bang to within a few hundred million years.”

This will give scientists new insights into the Universe’s infancy, according to Taylor. “We will be able to map the Universe to an unprecedented depth.”

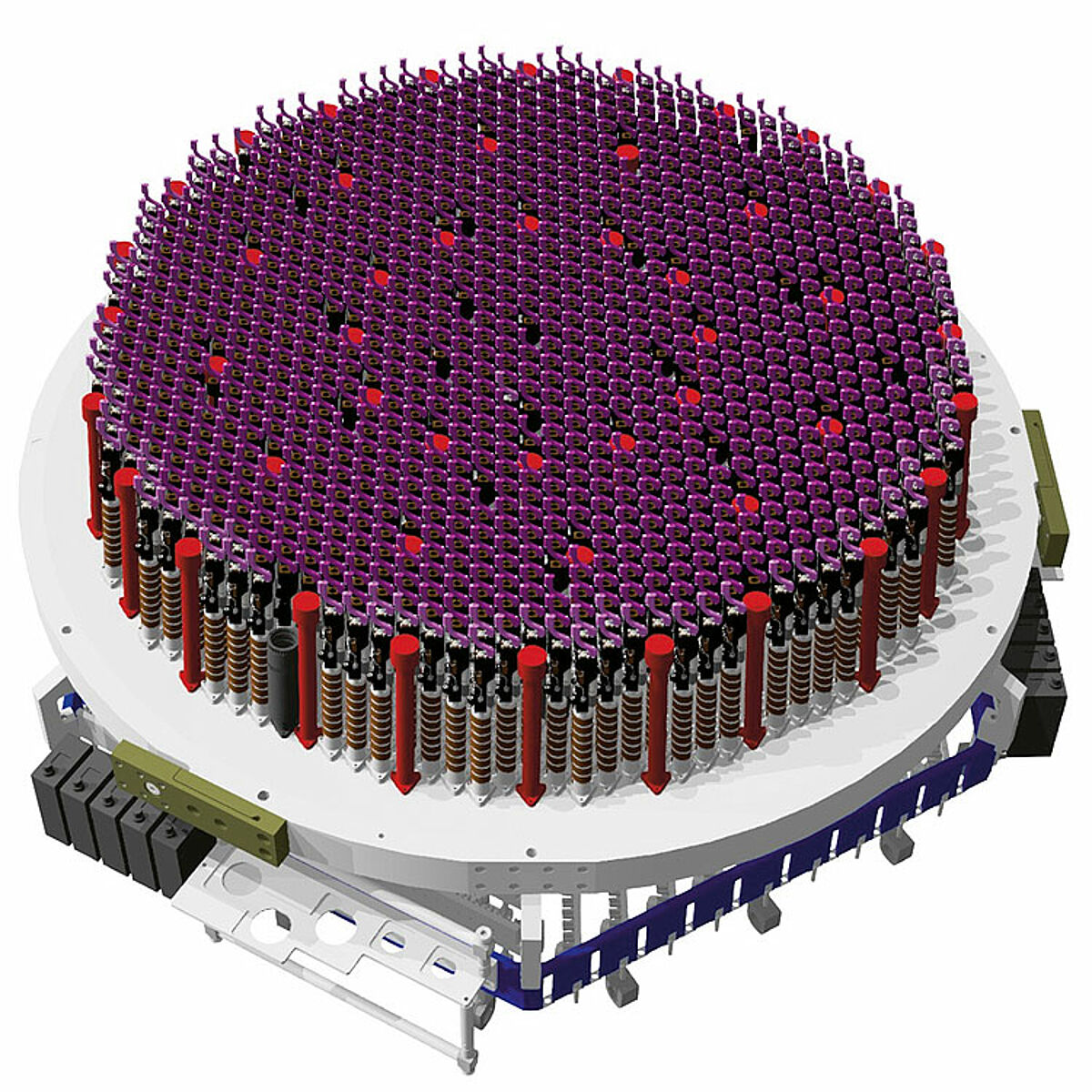

The astronomers aim to target several million objects over a period of about five years. To reach that aim, the 1,001 optical fibers of the spectrograph have to be pointed at the cosmic targets quickly and mostly automatically. This is achieved with an equal number of fiber positioning units (FPUs). Each FPU has two stepper motor drive units fitted to reduced-backlash spur gearheads. The one in the back moves the central axis (alpha) of the FPU. Eccentrically mounted on this, the front motor-gearhead drive unit (beta) simultaneously moves the fiber tip.

The combination of the two axial movements allows each FPU to cover a circular area within which the fiber can be randomly aligned. This area partially overlaps the areas of adjacent FPUs. That means that every point within the capture zone can be controlled.

To meet the challenging requirements regarding positional repeatability (essential for preventing collisions between FPU end tips) the drive system must be extremely precise … and must operate with high repeatability.

High-quality stepper motors come from FAULHABER PRECISTEP; the zero-backlash gearheads from FAULHABER Minimotor contribute to the positioning accuracy. FAULHABER subsidiary mps handles the mechanical design of the modules.

“We received very valuable input from all three participating companies of the FAULHABER Group,” reports Dr Steve Watson, who is responsible for the FPU development at UK ATC. “Without their unique know-how, it would’ve been impossible for us to develop this core module in this form, and above all in the kind of numbers we needed. In addition to the alignment speed of the optical fibers, they must also be highly precise. We reach an accuracy of 0.2° and a reproducibility of the position down to 20 µm.”

He continues: “Given the length of the FPU and the modular design, these are excellent numbers. Plus the units stay properly aligned to the focal plate on which the modules are arranged throughout all positions.”

The high precision and extreme reliability of the components allows the control to be kept simple, which is another requirement to operate the spectrograph flawlessly. Complex electronics and control logics would severely impede the quick and simultaneous control of 1,001 fibers. Thanks to the high quality of the components, precise alignment is achieved by means of simple open loop control. The technology must also be very sturdy and virtually maintenance-free to perform its tasks without interruption over the planned ten-year service life of the system.

Project manager Alasdair Fairley is already looking beyond such technical concerns: “We are making good progress with the MOONS. We expect to be able to install the spectrograph in summer 2021. Commissioning will take about half a year, so that we can probably start mapping at the beginning of 2022. We are confident that the FPU will remain fully operational for ten years without maintenance.”

The FAULHABER Group offers the world’s largest consolidated portfolio of miniature and micro drive system technologies available from one partner in the world today. The Group specializes in the design and manufacture of complex, high precision miniature and micro drive systems for challenging areas of application like medical devices, handling automation, telecommunications, and precision optics.

FAULHABER is known worldwide as a symbol of high quality, precision miniature drive systems, components and controls. With a technology focus on self-supporting skew-wound ironless-rotor dc motors as well as precision system components such as gearboxes, encoders, and motion controllers, FAULHABER has been built around the design, manufacture, and after-sales support of the three founding members of the FAULHABER Group. For more information, visit faulhaber.com/m/spectrograph/en.

Leave a Reply

You must be logged in to post a comment.