Materials and features of motion components for cleanroom environments balance competing demands such as cost and performance, performance and compactness, and ease of manufacturing and assembly with cleanroom satisfaction.

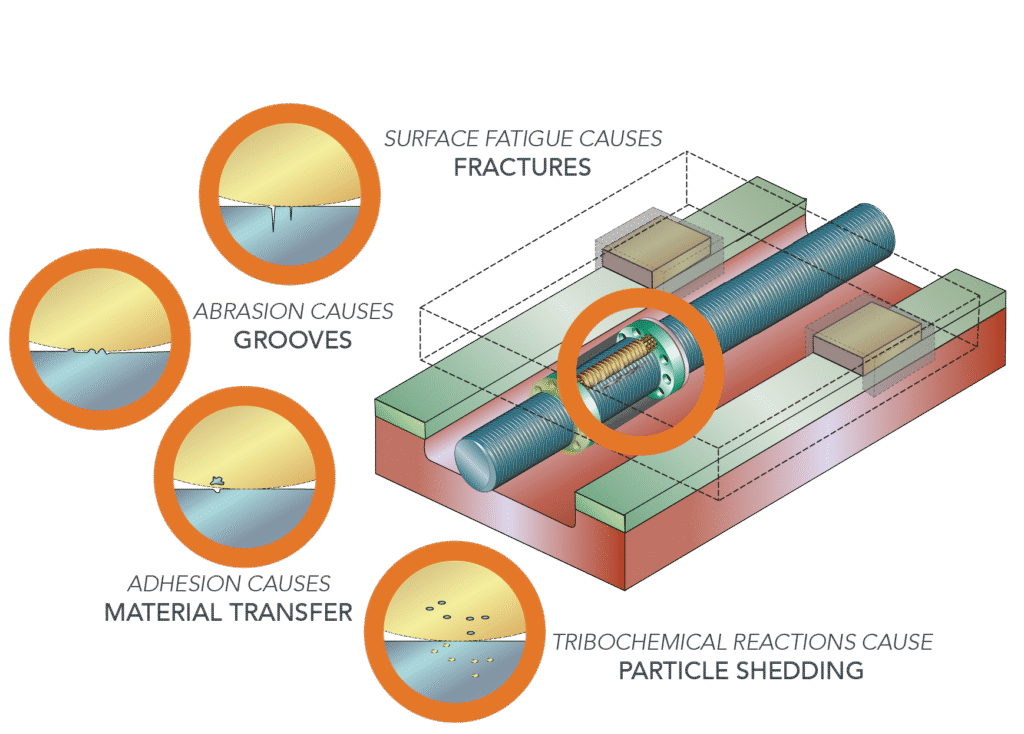

First thing first — reduce friction: One of two primary sources of particulate contamination that can degrade a cleanroom environment is people. The other is friction between moving components.

Related: Part one — How to specify motion components for cleanroom environments

Virtually every motion system involves friction between sliding or rolling surfaces — whether it’s linear bearings, rotary bearings, or meshing gears. Friction generates particles so reducing friction should be top priority.

Reduce friction from linear guides and drives: To minimize friction from linear guides, choose components with rolling contact or those with sliding contact only if explicitly certified for cleanroom use. Also avoid systems with high preload if possible. A non-preloaded miniature rail guide (for example) using two recirculating-ball rows emits significantly fewer particles than a preloaded standard guide with four recirculating-ball rows.

Because components in a cleanroom don’t need protection against contamination, it’s okay to use low-friction or noncontact seals. That’s in contrast with a typical industrial application for which seals and covers do need to protect the components. For example, on linear guides seals that don’t contact the raceways will keep lubrication and wear particles inside the actuator without themselves producing wear particles.

For linear actuators, static covers (no bellows) add another barrier against particles dispersing into the cleanroom.

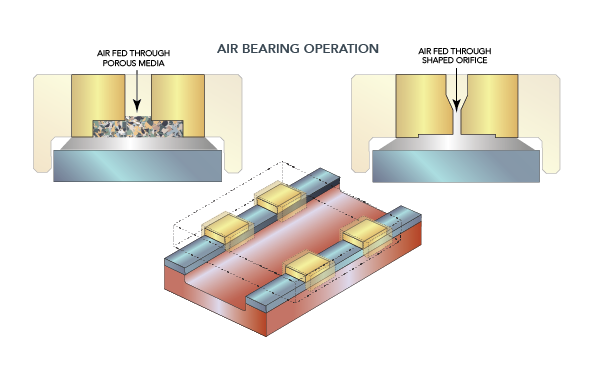

Systems with reduced contact and friction: Air bearings are another option (albeit relatively uncommon) for guiding and supporting loads. In cleanrooms, air bearings excel because they are completely noncontact. Another completely noncontact component is linear motors.

A linear-motor stage with air bearing guides in theory has no friction and so no particle generation.

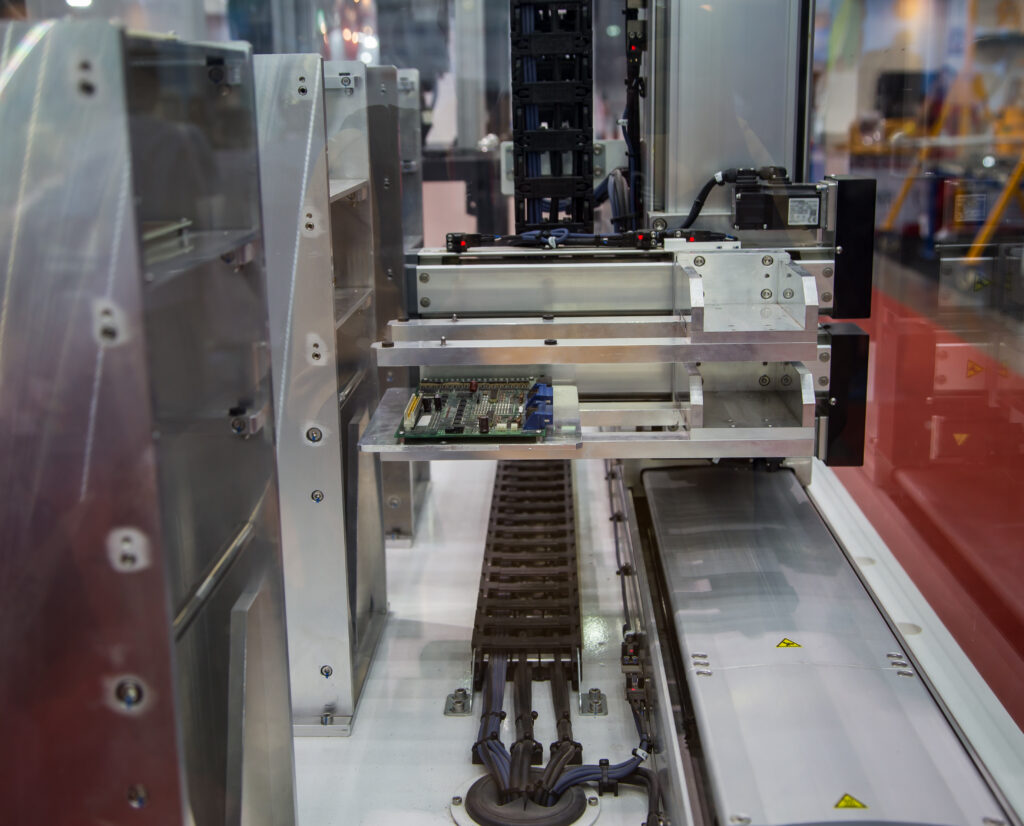

In real-world installations though, moving cables and cable carriers can generate particles. So, some cable manufacturers offer products with special low-friction coatings to minimize particle generation; cable tracks with abrasion-resistant joints can also help reduce wear between sections.

One such make of these air bearings integrates them into both linear and rotary bearing slides, XY air bearing tables, rotary tables and spindles, and tip-tilt stages. Also on offer are three-degree-of-freedom spherical air bearings.

A solution to the problem of particle generation due to friction is to use noncontact components and systems. For example, some linear-motor stages have air bearings. The cable can be a flat self-supporting type that doesn’t need a cable carrier.

Air-bearing guides complement multi-axis stages with noncontact movement of loads.

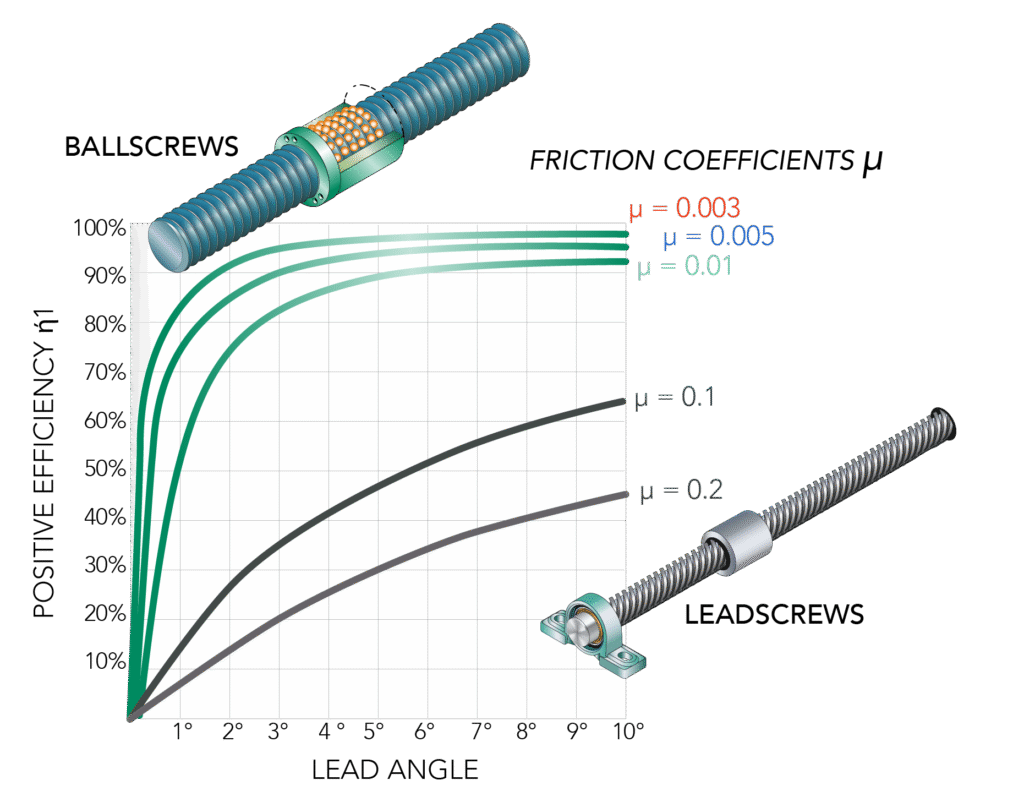

When it comes to linear drives in cleanrooms, conventional wisdom is that belts and chains should be avoided as they involve significant contact and wear. Advances in belt materials especially though — and seals for belt drives within actuator bodies — means they’re increasingly common in cleanrooms. Similarly, rack-pinion sets involve high-friction meshing and wear, so conventional wisdom is that they should also be avoided. Real-world exceptions abound though.

All this said, ballscrews are typically the default choice for linear drives in cleanroom applications. Of course, ballscrews need lubrication and screw rotation can cause lubrication splatter. Here again, low-friction or noncontact seals help keep lubricant inside the ball nut and protect the cleanroom.

We’ve touched on the noncontact nature of linear motors. But common linear-motor arrangements operate with the forcer (primary part) moving. So cables move as well … and in fact, cables are another source of particle generation. So, sometimes a better configuration for cleanroom applications is to keep the forcer (primary) and cables stationary, while allowing the magnet track (secondary) to move.

Reduce friction from cables and cable management: Another source of friction and particles is cable assemblies. Round cables shed particles if they rub the carrier. So, it’s good practice to (if possible) reduce the overall cabling for a given design — with (for example) integrated motor-drive units instead of separate motors and drives.

For the power, feedback, and data cables, those with low-friction coatings to minimize particulates and reduce outgassing.

Round cables with anti-friction coatings are acceptable, as are cable carriers with abrasion-resistant joints. Preferred are self-supporting flat cables as well as any opportunities to reduce cabling.

Cable carriers used in cleanrooms should have low vibration, low-abrasion fastening, and smooth interior surfaces to prevent abrasion of cables.

Reduce friction from rotating equipment (including motors and gearboxes): Rotating equipment in motion applications (such as motors and gearboxes) use rotary bearings … and gearboxes involve meshing teeth … and these are friction and particle generators. Fortunately, these components are enclosed, so particles are less likely to escape into the cleanroom environment. Plus, a wide range of cleanrooms and compatible lubricants can be used in the high-speed high-load conditions found in motors and gearboxes.

To improve cleanroom compatibility, it’s also possible to impart slight vacuum to the motor or gearbox housing to safely extracts particulates from the cleanroom. Fully enclosed housings are acceptable; a vacuum purge is preferred. Vacuum purge ensures particulates from closed systems can’t escape into the cleanroom environment. Some pre-engineered wafer aligners have pumps for a vacuum of -0.05 to -0.08 Mpa.

Leave a Reply

You must be logged in to post a comment.