Open architecture HMI can provide benefits such as increased flexibility for motion control, leading to more efficient machine designs.

Ramey Miller

HMI Marketing Manager

Siemens

Designing industrial machines with motion control for manufacturing is a critical aspect of modern industrial automation. These systems regulate the movement of mechanical components, such as motors, actuators, and conveyors, within industrial machines. Motion control systems are pivotal in ensuring manufacturing processes’ precision, efficiency, and reliability. The design of industrial machines with motion control is a multidisciplinary task that involves precision engineering, advanced control algorithms, sensor integration, and a focus on energy efficiency. Implementing these principles results in highly efficient and reliable manufacturing processes, contributing to increased productivity and quality in industrial settings.

One key consideration in designing such machines is the need for precise and coordinated motion. This involves implementing advanced control algorithms that can synchronize multiple axes of movement to achieve intricate manufacturing tasks. Whenever precision tasks are automated in manufacturing processes, the motion control systems ensure that every movement is accurate and repeatable. Feedback from sensors, such as encoders and vision systems, allows the machine to adjust and optimize its movements constantly in real-time. This closed-loop control mechanism enhances the accuracy and reliability of the manufacturing process. Efficient energy usage is also a priority in designing industrial machines. Manufacturers can optimize motion control systems to minimize energy consumption. This not only reduces operational costs but also aligns with sustainability goals. The machine operators must monitor and control all these critical functions via human machine interfaces (HMIs).

Insight and input – motion control HMI

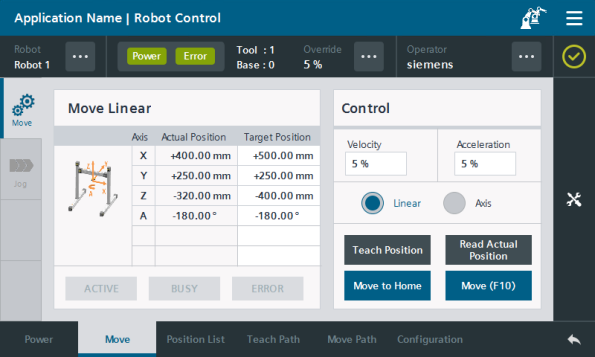

Considerations for user-friendly interfaces and programming flexibility are essential for motion control. Machine designers must include intuitive user interfaces (UIs) that streamline the user experience (UX), reduce onboarding and training costs, and enhance efficiency and safety. In addition, UIs must provide programming environments that allow customization for specific manufacturing requirements. The interface between human operators and industrial machines with motion control is a critical element in ensuring optimal performance and efficiency in manufacturing.

Engineers face the challenge of designing these intuitive interfaces that facilitate seamless communication and control for operators, enabling them to interact with complex motion control systems effortlessly. An intuitive interface is user-friendly and accessible, allowing operators to monitor and control the machine with minimal training. Graphical user interfaces (GUIs) with clear visualizations of machine status, movement trajectories, and diagnostic information enhance operator understanding. Touchscreen displays and interactive controls contribute to a more intuitive user experience, reducing the learning curve for operators and minimizing the risk of errors.

As manufacturing processes become increasingly diverse and customized, the need for adaptable programming environments becomes paramount. Engineers must develop software interfaces that allow operators to program and customize motion control parameters to suit specific manufacturing requirements. The software must also have the flexibility crucial in accommodating variations in product designs, production volumes, and process intricacies – which often means customization. Customizable programming environments empower operators to do more than modify motion profiles, adjust acceleration and deceleration rates, and fine-tune trajectories based on the unique characteristics of the products being manufactured. Truly customizable programming environments let engineers fully customize the interface to match the process.

This adaptability is particularly valuable in industries with expected rapid product changes and short production runs. Integrating intuitive interfaces and customizable programming environments contributes to overall system efficiency and reduces downtime. Operators can quickly respond to changes in production needs, troubleshoot issues effectively, and optimize machine settings without requiring extensive technical expertise. This enhances operational agility and supports continuous improvement initiatives within the manufacturing environment. Designing intuitive interfaces and customizable programming environments is a pivotal aspect of motion control system development. By prioritizing user-friendly interactions and flexibility in programming, engineers empower operators to harness the full potential of industrial machines, fostering efficiency, adaptability, and responsiveness in the ever-evolving manufacturing landscape.

Optimizing HMI design — balancing cost-efficiency dynamics

In the realm of machine design, a compelling dynamic emerges when weighing the option of a single industrial HMI for cost savings against the efficiency gains associated with more HMIs. Opting for a singular HMI minimizes initial costs, reducing hardware and software customization costs while simplifying the control interface. However, this streamlined approach may limit operational efficiency, as it often requires operators to manage diverse tasks on a single screen. Conversely, investing in multiple HMIs incurs higher upfront costs but provides the advantage of enhanced task specialization, real-time monitoring, and streamlined communication. The trade-off lies in finding the equilibrium between affordability and operational effectiveness, where a judicious investment in more HMIs can yield long-term efficiency benefits that outweigh the initial expenditure.

Designing machines with multiple HMI stations offers significant advantages in processing, handling, machining, and various other industrial applications but has often been cost-prohibitive due to the high cost of HMI hardware and customization. With more than one HMI station, each operator can focus on specific aspects of the process, improving overall efficiency. Even though more HMIs allow for enhanced collaboration among operators and promote better communication and coordination in complex manufacturing environments, the costs to scale these optimized solutions have led machine designers to use fewer HMIs in the machine design stage.

In processing, having separate HMIs for different stages allows operators to monitor and control individual steps closely, ensuring quality and precision. For handling tasks, more HMIs enable simultaneous control of various material handling systems, reducing bottlenecks and optimizing throughput. In machining, where precision is paramount, multiple HMIs enable operators to simultaneously monitor different facets of the machining process. This real-time oversight enhances quality control and allows for quick adjustments to optimize production. Using more than one HMI in industrial processes enhances operational flexibility, promotes efficient collaboration, and allows for specialization, improving productivity and quality in processing, handling, machining, and other manufacturing operations.

Cost-efficient open architecture HMI

A strategic approach involves harnessing the benefits of a single higher-cost HMI endowed with a plethora of features, complemented by additional lower-cost HMIs with more specialized functions. The high-cost HMI serves as the central hub, consolidating comprehensive control and monitoring capabilities into a single interface. This powerhouse can manage critical, overarching operations, providing operators with a holistic view of the system.

Supplementing this with lower-cost HMIs tailored for specific tasks introduces a layer of operational efficiency. These specialized interfaces can be strategically placed at critical points in the manufacturing process, allowing operators to focus on dedicated functions without the cognitive load of navigating an all-encompassing interface. For example, a dedicated HMI for quality control or material handling can streamline operations and reduce the risk of errors.

Flexibility is enhanced (and machine costs reduced) by using open-architecture HMI in machine design. Open architecture means that the HMI is compatible with various industry-standard hardware and commercially available software solutions. Open architecture HMIs use industry-standard networking and cybersecurity (UMC/UAC), HTTPS encryption, and browser-based interfaces that allow for easy customization while offering features such as multi-touch displays that are familiar to operators, making them easy to onboard.

This approach strikes a balance between cost-effectiveness and operational prowess. The design investment in a high-cost, feature-rich HMI is justified by its ability to streamline complex operations and facilitate comprehensive control. Simultaneously, the judicious integration of lower-cost HMIs optimizes task-specific workflows, enhancing efficiency and responsiveness. The synergy between the centralized, high-cost HMI and supplementary, task-specific HMIs culminates in a harmonized system that maximizes operational effectiveness and cost-effectiveness in industrial machine design.

Flexibility in designing efficient machines

Employing multiple HMIs in motion control machine design yields a spectrum of benefits. A central high-cost HMI as the primary control hub offers a comprehensive overview of the entire system, and this centralized interface streamlines complex operations and enhances the machine’s overall efficiency. Supplementing this with lower-cost open-architecture HMIs for specific functions optimizes task-specific workflows. Operators can focus on dedicated functions without navigating through an intricate interface, increasing operational responsiveness and creating competitive advantages in process agility.

The judicious integration of these interfaces strikes a balance between cost-effectiveness and operational prowess, ultimately maximizing the overall efficiency of motion control machine design. Using open-architecture systems ensures broad compatibility, easy customization, and scalability. This approach leverages the strengths of each interface, creating a synergistic system that delivers enhanced performance, adaptability, and responsiveness in industrial settings.

Siemens

siemens.com

Leave a Reply

You must be logged in to post a comment.