As more companies look to automate processing lines, they’re relying on conveyor manufacturers for an assist. Here’s why.

By Mike Hosch • Vice President – Industrial Products • Dorner Mfg.

Automation demands efficiency, and conveyors are one technology to enhance the productivity of processing lines. No wonder then that conveyors have become integral components in all phases of the automation, assembly, and industrial markets. What’s more, while some of the dominant global brands have been early adopters to embrace the full potential of conveyors, more companies of all sizes are taking a closer look at how they too can better integrate conveyor systems to ultimately improve entire lines.

Though integrating such conveyor systems can be daunting — especially those meant to become an integral part of larger processes — manufacturers offer help. The first step is to evaluate application and determine the expectations for conveyor system. Even for this step, resources about to make this process easier.

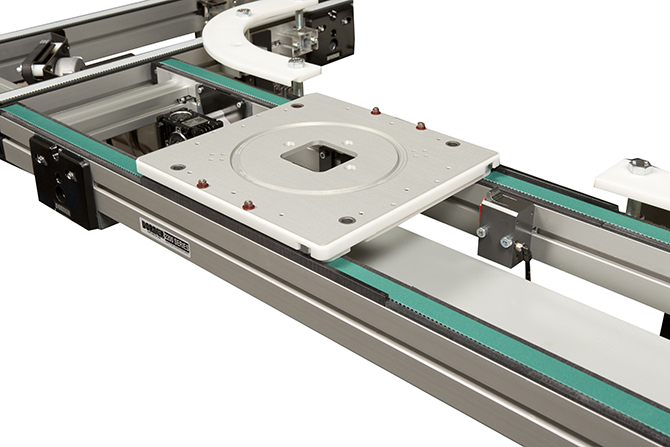

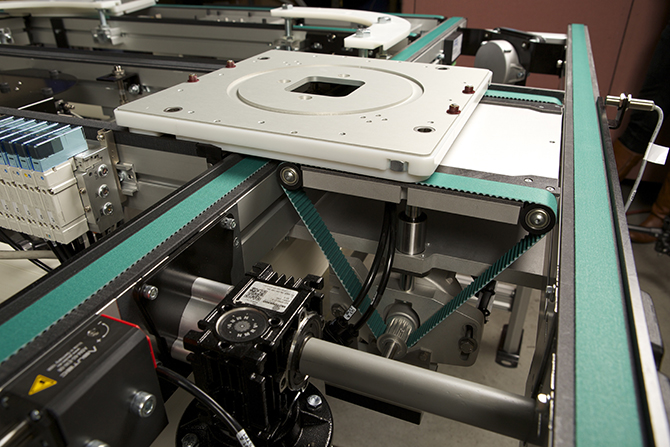

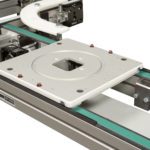

Pallet conveyors coordinate tasks: The manufacturing environment inside facilities is much different than what it was a generation ago. Automation is now a prime driver behind the way products are produced. Many applications include both manual processes and robotic interaction … so conveyors today must be engineered to meet these challenges. That’s why pallet system conveyors have become a popular choice.

Pallet system conveyors are suitable for many automation-focused applications that need exact movements and positioning of parts, as they can be setup or programmed to start and stop at specific intervals to synchronize with robotics or other processes. These conveyors dominate automotive-component manufacturing and other industries — including medical devices, electrical and electronics, and product testing and inspection that require automated and manual assembly (or handling) of products.

Pallet system conveyors typically come on three different platforms to convey the pallet:

- A dual-belt configuration powered by a common drive

- A flexible plastic chain or belt design

- A linear motor

Pallets can stop and raise up off the belts or rotate the pallet 90° or 180° to reposition product as needed. Companies using pallet-system conveyors are leveraging their accuracy. These conveyors put products at exact locations — and conveyor lift and location stations deliver repeatability of 0.002 in. Pallets can come in either square, rectangle, or octagon shapes; they can make tight turns and travel up inclines or down declines as well.

Pacing conveyors to stagger items: Another type of conveyor that’s increasingly common in manufacturing automation and packaging are pacing conveyors. These conveyors take randomly spaced products and orientate them into even spacing for packaging, machine infeed, or other processes.

The system usually has two variable speed belts and a moveable conveyor junction. This two-belt design allows pacing conveyors to operate at a faster rate than a standard one-belt conveyor.

As randomly spaced products enter the conveyor, a photo eye detects the product spacing. Then a servomotor control automatically varies the conveyor speed and conveyor junction placement to evenly space product. Pacing conveyors are completely noncontact sand contain no guides, diverts, or plows. Usually these conveyors have HMI interfaces to let operators set the spacing, speed, and orientation of products. That in turn helps applications that require the merging multiple lanes together without product stops or gates.

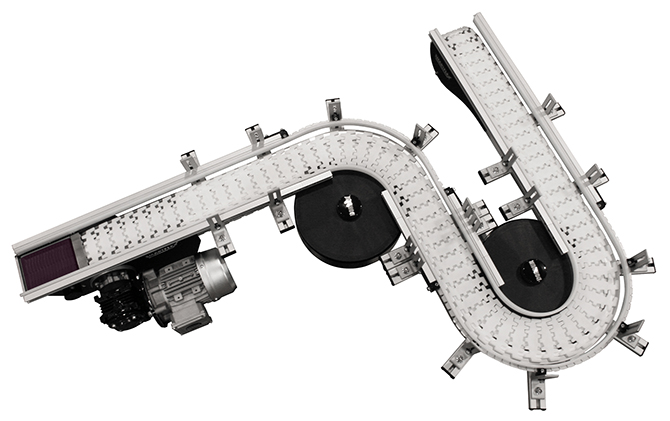

Flexible chain conveyors for tight spaces: Some application designs need products moved in and around equipment and machinery. Here, conveyors must be flexible and make tight turns. Flexible chain conveyors are a good fit here. Automated applications within processing and packaging, industrial, medical, life sciences, and health and beauty industries often operate in tight spaces or in plants that require product elevation changes (for storage and space management) so are benefit from integration of flexible chain conveyors.

In fact, the flexibility of these conveyors extends past the platform itself. Their ability to twist, turn and snake around tight places gives design engineers and plant managers the flexibility to easily integrate the conveyors with existing equipment.

Precision timing-belt conveyors: Many industrial automation, product assembly, manufacturing, and packaging applications need product in exact spots on the conveyor at the right time. Precision timing-belt conveyors excel here. Powering the conveyor to deliver accurate alignment of time and distance are servomotors that provide indexing repeatability of ±0.040 in. at a rate of 100 indexes per minute. This level of precision is critical — especially in robotic applications.

Selecting the right pallet conveyor system

Clearly there are many conveyors engineered for automation-type applications, but the objective is to select the right one for a given application. Conveyors built to specification improve production-line efficiency and output. So there’s no reason to settle for a conveyor that’s shoehorned into application, especially when a system can be engineered to seamlessly integrate into a larger process.

But to do that requires an understanding of what the goals and expectations are for conveyors. In other words, what must the conveyors to do? Knowing this upfront establishes a good foundation for a successful conveyor installation.

Whether the conveyor system is to serve the operations of an OEM or integrator, a small family-owned shop, or a multinational business, there are common design concerns regarding new conveyor installations. Begin to outline the conveyor objectives by answering these questions:

How will the conveyor system integrate with what the plant is trying to build?

What is the height, weight and shape of the product(s) being moved?

What’s the targeted rate of production?

How much space is available for the conveyors?

Is space likely to be tight, needing conveyors to make sharp turns or go up inclines?

Is the machine or production line manual or automated?

Is the anticipated flow of production linear or oval?

Quantifying this information upfront helps get a more complete picture of the application — and define the project scope to let the conveyor supplier streamline the quotation process.

Application expertise for pallet conveyors

Consider the above questions to envision how conveyors should interact with the processing line or project into which they’re integrating. All components within an assembly automation application (including conveyors) should work together optimize the overall operation. Answering the above questions can also identify where improvements in product flow and handling can be made. Such analysis may determine no improvements are necessary — and that’s great. But if a planned conveyor system isn’t quite meshing with other application systems, or it appears as though the target output is in jeopardy, reviews can help … and in fact, this is where reputable conveyor suppliers prove their worth.

Perhaps more valuable than the actual conveyors are supplier knowledge and experience integrating designs for material handling and industrial automation. Collaborative discussions with conveyor suppliers and identifying potential design roadblocks is a great way to start. Some suppliers accept responsibility for the ultimate design and do heavy lifting to supply conveyor systems that are specifically optimized for the application at hand.

Of course, collaboration doesn’t necessarily result in custom conveyor designs — because after all, standards offerings are less costly than custom. But good supplier recommendations are typically based on using standard products as much as possible while integrating custom designs where needed to ensure reliability and flexibility. That’s why a one-size-fits-all conveyor isn’t always the best choice. The goal of a well-designed conveyor system is to serve the process … and not to fit the process to the conveyor.

Mike Hosch is V.P. of industrial products for Dorner Mfg. Email him at Mike.hosch@dorner.com. Also visit Dorner Mfg. at www.dornerconveyors.com.

Leave a Reply

You must be logged in to post a comment.