by Hilary Whiting, Manufacturing Engineer, Advanced Manufacturing, Kollmorgen

With scientifically verified hygienic design principles, motor manufacturers are designing motors for food and beverage applications that dramatically improve safety.

The food and beverage industry is one where safety is paramount. That’s why food and beverage companies and their machine suppliers are battling constantly to keep their products safe. These microscopic battles are fought with large quantities of water and chemical sanitation processes. Hygienic machine design is critical even down to the sub-component level in order to allow these processes to be effective in removing product residues as well as pathogens, and destroying bacterial intruders.

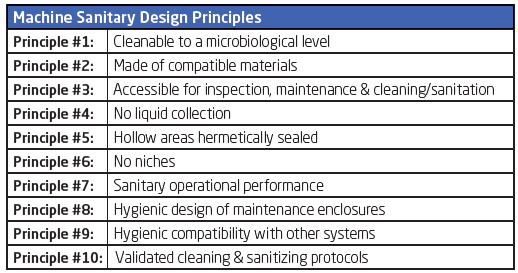

Both the North American Meat Institute (NAMI) and the European Hygienic Engineering Design Group (EHEDG) have published lists of Hygienic Machine guidelines (See Table 1). One of the challenges in meeting these guidelines is the design of components such as motors, gearboxes, and sensors.

Kollmorgen set out to verify the benefits of hygienic machine design by partnering with the Virginia Tech Department of Food Science and Technology (VT FST). These hygienic design principles could then be applied to the design of servomotors used in the food and beverage industry.

Scientific testing

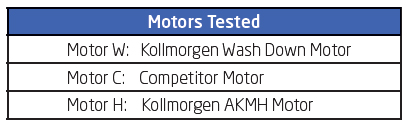

A series of tests were conducted to determine the sanitizability of three servomotor designs. The three motors tested were an industry standard IP67 wash down servomotor designated as Motor W, a stainless steel motor used in the food and beverage industry designated Motor C, and a stainless steel servomotor designed to comply with the NAMI hygienic design checklist and EHEDG design parameters designated Motor H. These motors represent the most common types used in food and beverage equipment.

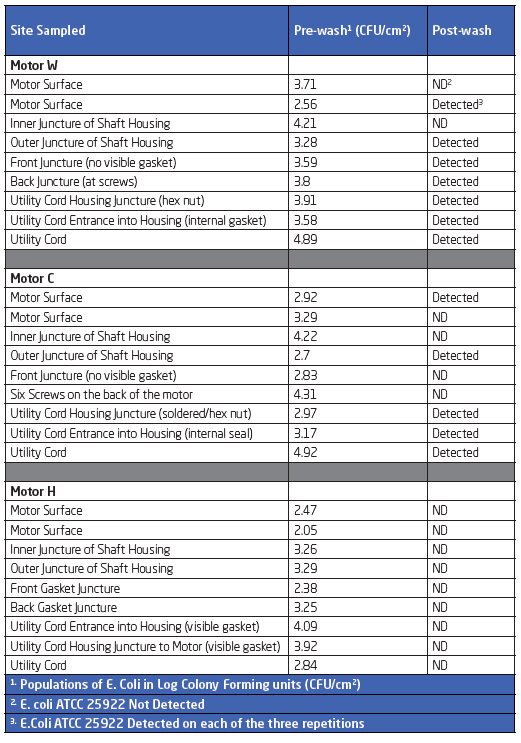

Each motor was inoculated with ATCC 25922 strain of E. coli. The study focused on determining the sanitizability at areas of concern on the motor’s surfaces including labels and surface finish, seals and fasteners, and cabling. The team focused on these areas to see how design features affected the ability of the servomotor to be sanitized of E. coli. These areas were marked and isolated, then put in contact with 10 μl of E. coli for one hour. During this time, the motors were run at amperage that kept their surface temperatures between 33 °C and 38 °C, non-lethal temperatures for E. coli.

Sites were inoculated with E. coli and sampled prior to the cleaning and sanitation procedure (pre-wash) to determine a baseline. A typical industry cleaning and sanitation procedure supplied by a leading food production company was used to clean and sanitize each of the motors. The marked sites were sampled again post-wash to determine if the area was successfully sanitized. The test included three repetitions of this process to provide an appropriate data sample size. The reported study findings can be seen compiled in Table 3. This data could then be used to draw conclusions about the impact of design features on the sanitizability of the three motors.

Label and surface finish testing results

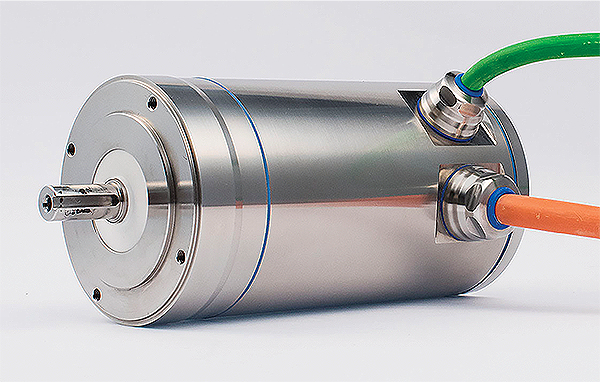

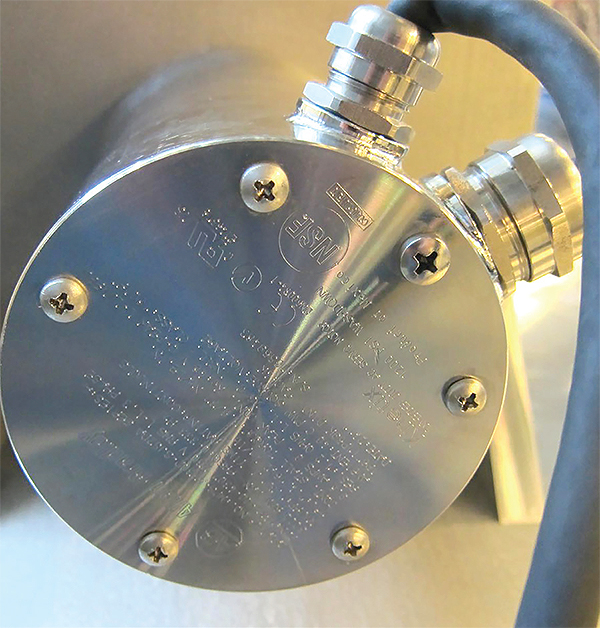

The first sets of locations to be evaluated are those pertaining directly to labeling and surface finish on the motors. Motor W has labels etched onto the surface of the aluminum housing (Figure 1) and the surface is covered with food grade paint. The rough finish of the etched label was identified as high risk to harbor bacteria. Motor C has stamped labeling with a brushed surface finish on its housing (Figure 2). The brushed surface finish of Motor C was identified as an area of concern due to the textured surface finish, so was targeted as a sampling location by the test team. Motor H has a smooth stainless steel housing that holds a 32 μ-in. surface finish or better, even across the annealed label face (Figure 3). In the NAMI guidelines Principal 6.1 states; “It is recommended product contact surfaces textures shall not exceed 32 μ-inches…” The housings and labeling methods of Motor W and Motor C do not comply with this guideline, but Motor H is compliant. Both Motor W and Motor C were found to have E. coli present on their surfaces post-wash, whereas Motor H was not found to have any. So the lack of bacterial recovery post-wash from Motor H supports the NAMI design guidelines regarding surface finish and external materials as verified through the scientific testing.

Seal and fastener testing results

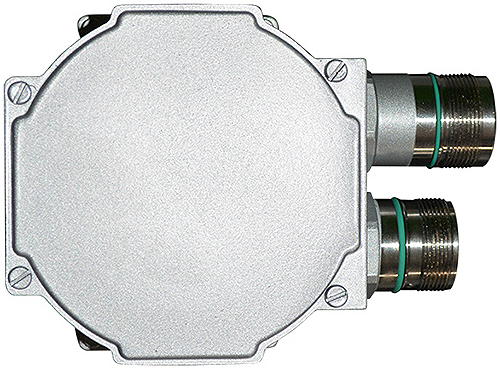

Seals and fasteners were the second group of test locations investigated. The NAMI guidelines caution against the use of fasteners above product areas in Principle 7 as well as stating that seals and O-rings must be designed to minimize product contact, Principle 2.9. Most standard fasteners create niches or spaces where microorganisms and product can be harbored. Principle 6 of the NAMI guidelines explicitly outlines the need for elimination of niches. Both Motor W and Motor C have external screws, a shaft seal, and several metal-to-metal joints (Figures 4 and 5) while Motor H has hygienically designed gasket joints instead of metal-to-metal joints, as well as a shaft seal, and does not use any external screws or fasteners. Motor W was found to have bacteria present post-wash on all of its junctures except the seal surface where the shaft was spinning. Motor C was found to have E. coli present on the outer juncture of the shaft seal. However, on the surface of Motor H, E. coli bacteria were not found to be present on any external sealing surface after sanitation. So here again, the lack of E. coli recovery supports the NAMI design guidelines regarding fasteners and junctures.

Cable and hardware testing results

The third area examined on the test motors was the cables and hardware. The NAMI guidelines do not explicitly address cables, but the general material guidelines can be applied in addition to Principle 6, the elimination of niches. Both Motor W and Motor C were found to have bacterial colonies on the cable and both cable fitting interfaces. The VT FST test team was not able to recover any E. coli on the cable or the cable junctures for Motor H, post-wash. The cable of Motor H was specifically designed to not harbor bacteria and withstand harsh wash down procedures. The cable connection to the motor is also sealed using a bushing interface instead of a metal to metal interface like Motor W and Motor C. Here, too, the lack of post-wash bacterial recovery on Motor H supports the NAMI guidelines regarding material specifications and niche elimination.

In summary, the hygienically designed Motor H outperformed Motor W and Motor C with regards to hygienic design. The VT FST team could not detect E. coli colonies on the exterior surfaces of Motor H post-wash while Motor W and C both had multiple positive sites after the sanitation procedure. The problem sites can be directly correlated to areas where hygienic design criteria were not strictly followed. Each bacterium that survives a wash down procedure may be a risk to food safety or quality, not only to food and beverage companies, but most importantly to the end consumers.

The data collected through this study points to the importance of system-wide hygienic design including purchased components. The importance of careful design on the servomotor component level can only be magnified when applied to entire machines and production lines.

The data also show that deviating from hygienic design standards corresponds to decreased motor sanitizability leading to increased contamination risk and the need for additional costly and time-consuming interventions. These risks translate to real world costs, whether it’s added sanitation time, increased numbers of cleaning interventions, reduced production time or increased risk of consumer harm when safeguards fail.

Kollmorgen

www.kollmorgen.com

Leave a Reply

You must be logged in to post a comment.