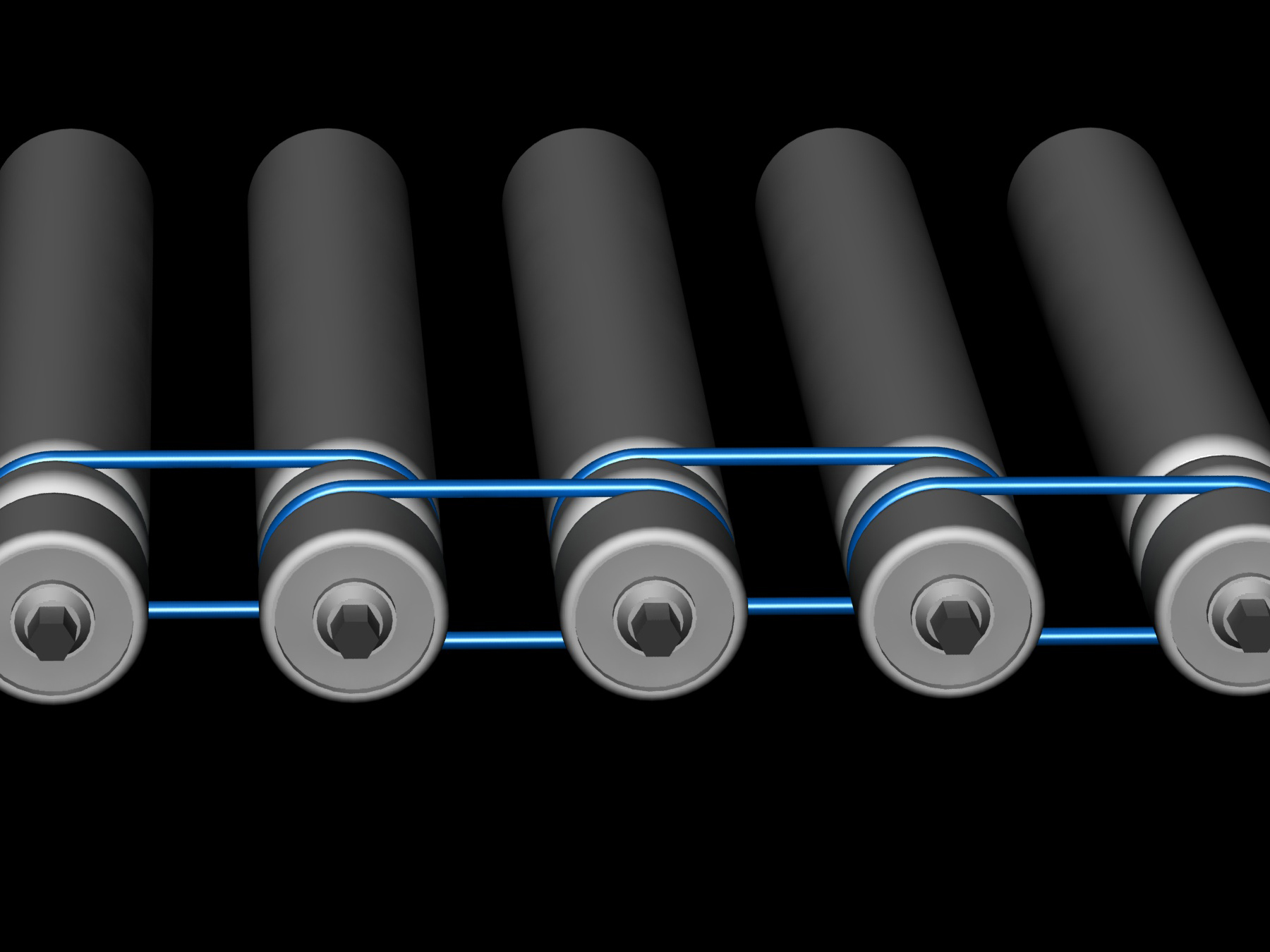

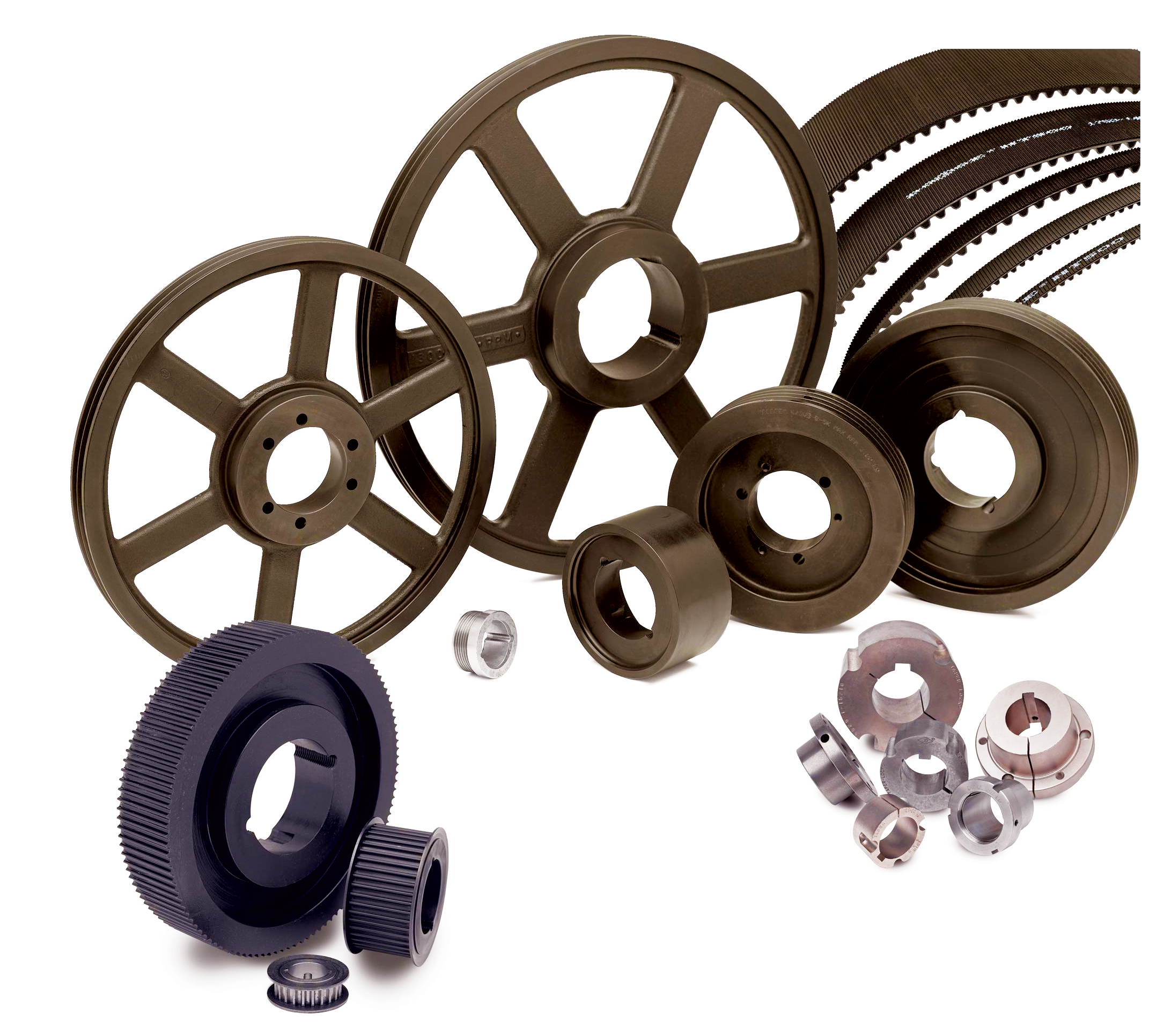

Updated May 2016 || Industrial belt drives consist of rubber belts that wrap around drive pulleys, in turn driven by electric motors. In a typical setup, the belt also wraps around one or more idler pulleys that keep the belt taut and on track. More after the jump.

The main reasons that engineers pick drives with belts and pulleys over other options is that modern varieties require little if no maintenance; they’re less expensive than chain drives; and they’re quiet and efficient, even up to 95% or more.

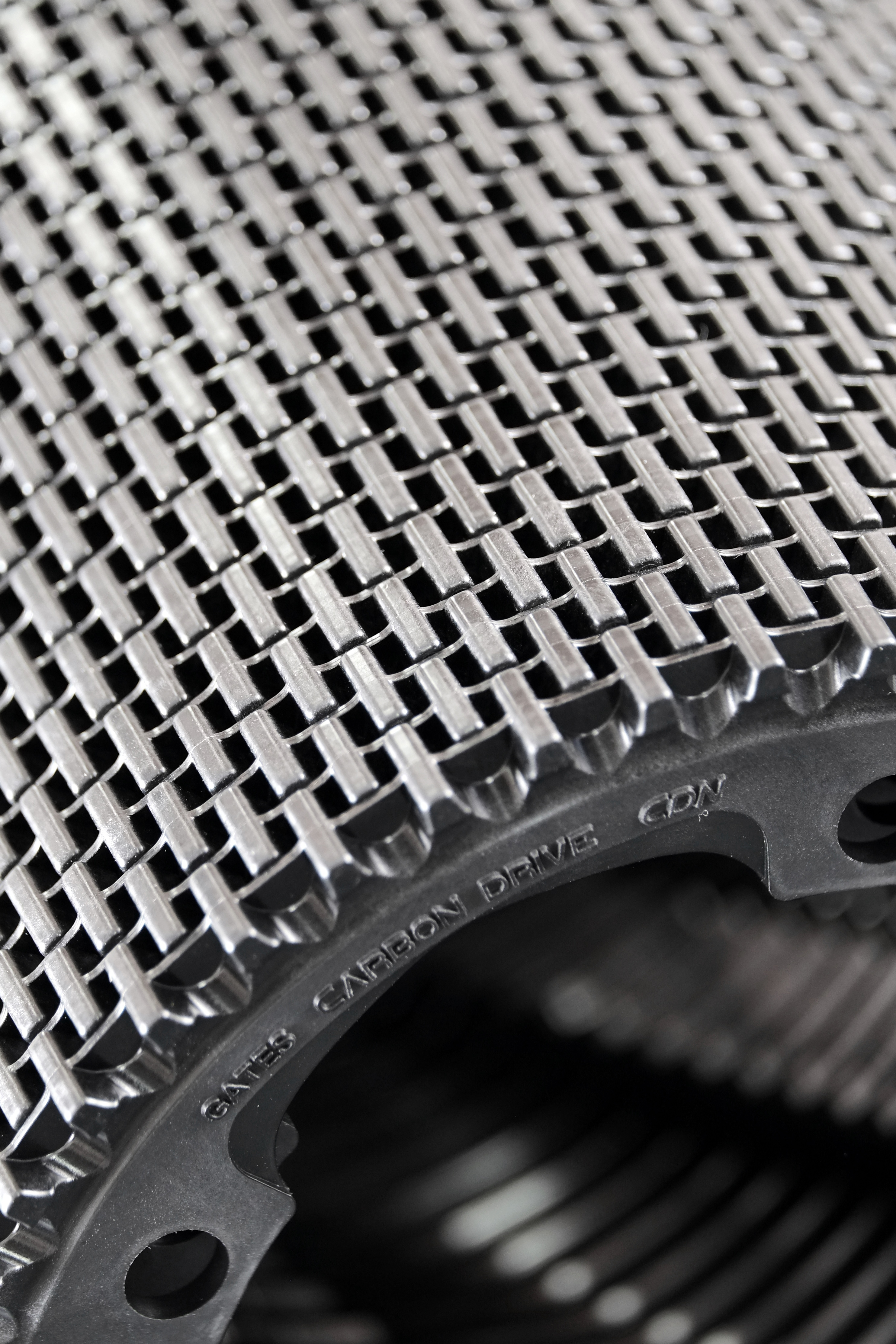

In addition, the tensile members of today’s belts—cords embedded into the belt rubber that carry the majority of the belt load—are stronger than ever. Made of polyester, aramid, fiberglass or carbon fiber, these tensile cords make today’s belt drives thoroughly modern power-transmission devices.

In addition, the tensile members of today’s belts—cords embedded into the belt rubber that carry the majority of the belt load—are stronger than ever. Made of polyester, aramid, fiberglass or carbon fiber, these tensile cords make today’s belt drives thoroughly modern power-transmission devices.

Manufacturers generally describe belts and pulleys with five main geometries. Pitch diameter is the drive pulley’s diameter. Center distance is the distance between the two pulleys’ centers. Minimum wrap angle is a measure of how much the belt wraps around the smallest pulley. Belt length is how long the belt would be if cut and laid flat. Finally, in the case of toothed belts (also called synchronous belts) the pitch is the number of teeth per some length—so a 3-mm pitch means that the belt has one tooth every 3 mm, for example.

How to apply

synchronous belts

Some general guidelines are applicable to all timing belts, including miniature and double-sided belts. First of all, engineers should always design these belt drives with a sufficient safety factor—in other words, with ample reserve horsepower capacity. Tip: Take note of overload service factors.

Belt ratings are generally only 1/15 of the belt’s ultimate strength. These ratings are set so the belt will deliver at least 3,000 hours of useful life if the end user properly installs and maintains it. The pulley diameter should never be smaller than the width of the belt. More after the jump.

As mentioned, belts are quieter than other power-transmission drive options … but they’re not silent. Noise frequency increases proportionally with belt speed, and noise amplitude increases with belt tension. Most belt noise arises from the way in which belt teeth entering the pulleys at high speed repeatedly compresses the trapped pockets of air. Other noise arises from belt rubbing against the flange; in some cases, this happens when the shafts aren’t parallel.

More after the video.

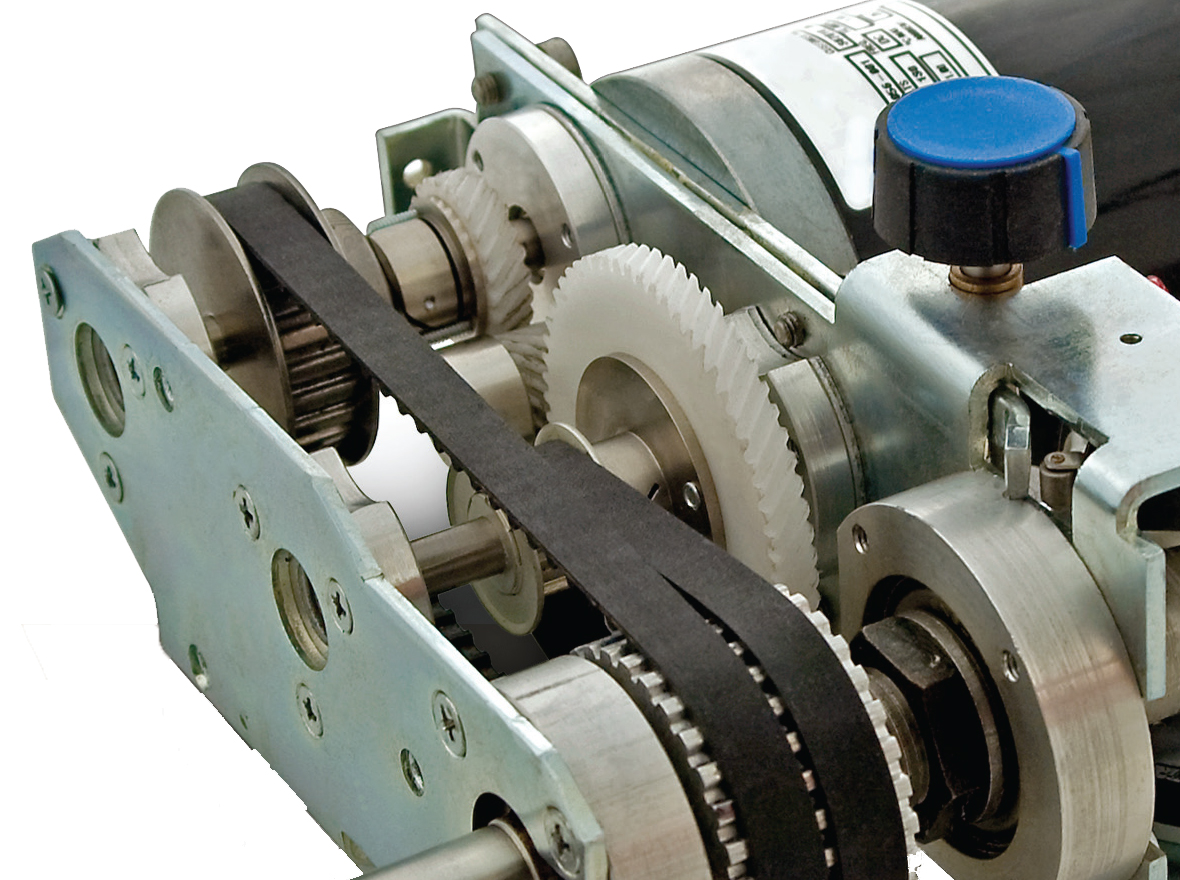

Pulleys are metal or plastic, and the most suitable depends on required precision, price, inertia, color, magnetic properties and the engineer’s preference based on experience. Plastic pulleys with metal inserts or metal hubs are a good compromise.

Tip: Make at least one pulley in the belt drive adjustable to allow for belt installation and tensioning. Also note that in a properly designed belt drive, there should be a minimum of six teeth in mesh and at least 60° of belt wrap around the drive pulley. Other tips:

• Pretension belts with the proper recommended tension. This extends life and prevents belt ratcheting or tooth jumping.

• Align shafts and pulleys to prevent belt-tracking forces and belt edge wear. Don’t crimp belts beyond the smallest recommended pulley radius for that belt section.

• Select the appropriate belt for the design torque.

• Select the appropriate belt material for the environment (temperature, chemical, cleaning agents, oils and weather). Belt-and-pulley systems are suitable for myriad environments, but some applications need special consideration. Topping this list are environmental factors. More after the jump.

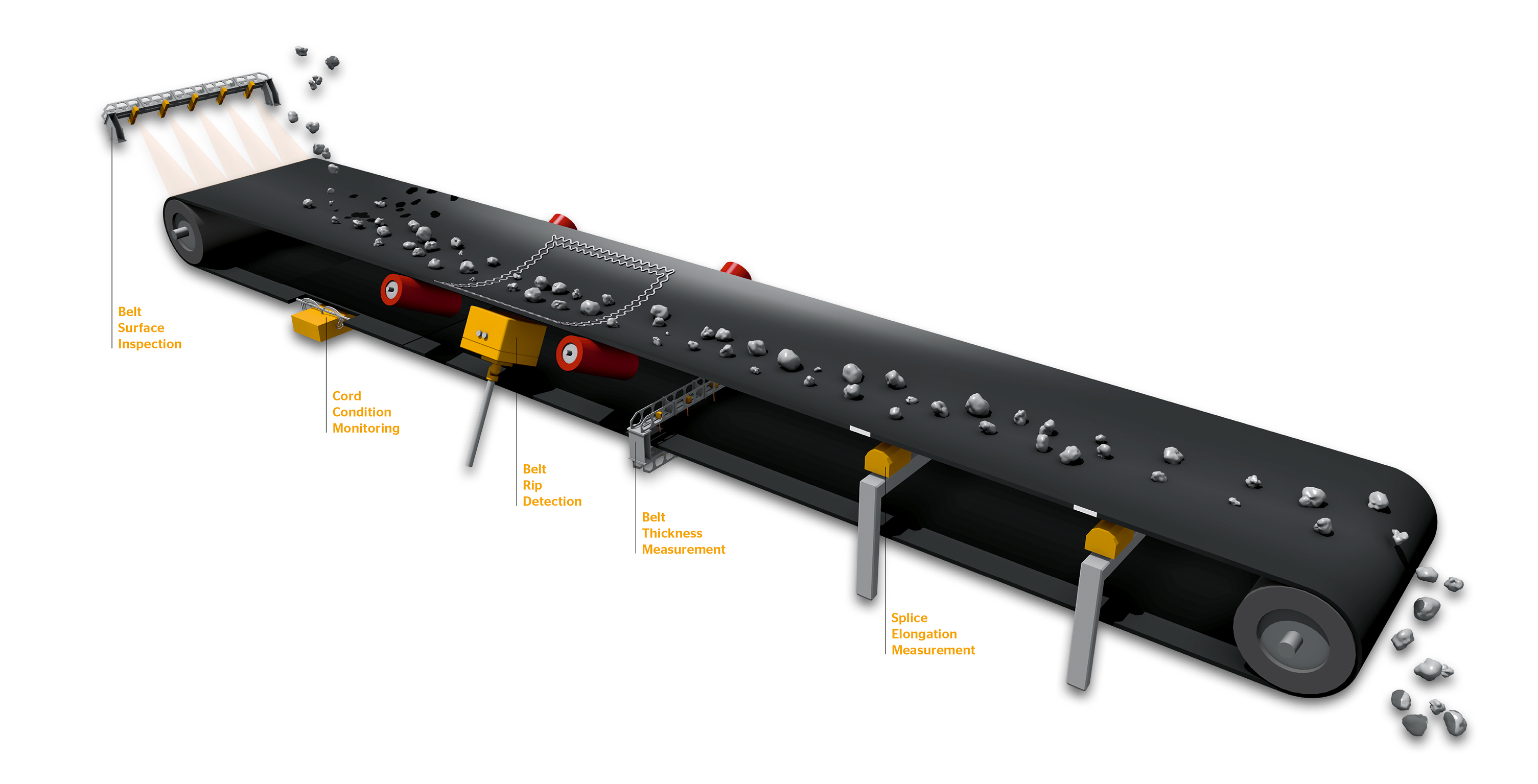

Dusty environments do not generally present serious problems as long as the particles are fine and dry. In contrast, particulate matter can act as an abrasive and accelerates belt and pulley wear. Debris should be prevented from falling into belt drives. Debris caught in the drive is generally either forced through the belt or makes the system stall. In either case, serious damage occurs to the belt and related drive hardware.

Light and occasional contact with water—during occasional washdowns, for example—has little serious effect. However, prolonged contact with constant spray or submersion can significantly reduce tensile strength in fiberglass belts and make aramid belts break down and stretch out. In the same way, occasional contact with oils doesn’t damage synchronous belts. But prolonged contact with oil or lubricants, either directly or airborne, significantly reduces belt service life. Lubricants cause the rubber compound to swell, break down internal adhesion systems and reduce felt tensile strength. While alternate rubber compounds may provide some marginal improvement in durability, it’s best to prevent oil from contacting synchronous belts.

The presence of ozone can be detrimental to the compounds used in rubber synchronous belts. Ozone degrades belt materials in much the same way as excessive temperatures. Although the bumper materials used in belts are compounded to resist the effects of ozone, eventually chemical breakdown occurs and they become hard and brittle and begin cracking. The amount of degradation depends on the ozone concentration and generation of exposure.

Rubber belts aren’t suitable for cleanrooms, as they risk shedding particles. Instead, use urethane timing belts here … keeping in mind that while urethane belts make significantly less debris, most can carry only light loads. Also, none have static conductive construction to dissipate electrical charges.

Leave a Reply

You must be logged in to post a comment.