Electric actuators range from syringe-sized units in medical applications to those that drive truck-sized industrial presses. These ubiquitous muscles of precision motion usually incorporate an electric motor and rotary-to-linear device for conversion of torque to linear force.

So let’s cover common motion applications for this component type.

No matter the application, electric actuators deliver precision and repeatability—indispensable for repeatedly moving loads to a given location or locations. In some cases, they’re also more controllable than fluid-power options, giving engineers a viable way to shape the speed, force and acceleration of machine-axis moves.

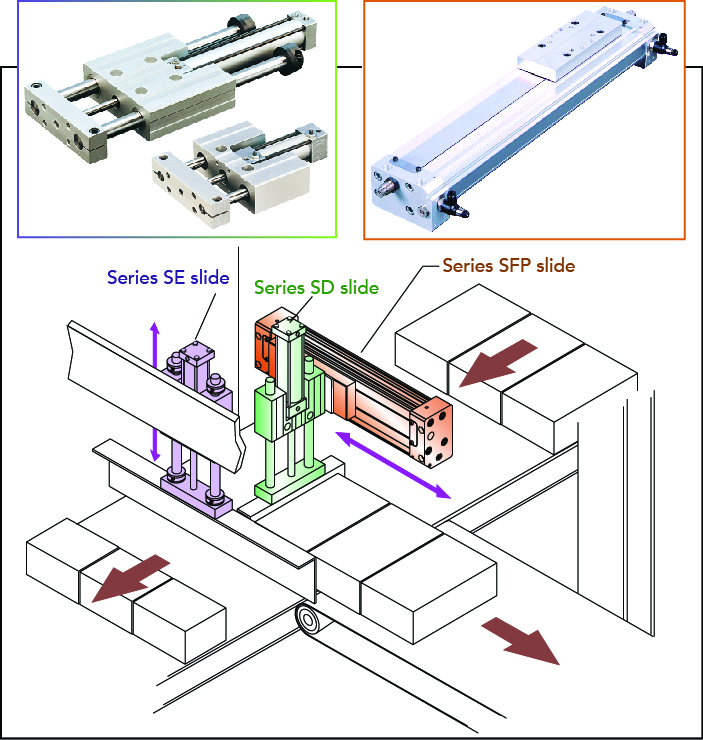

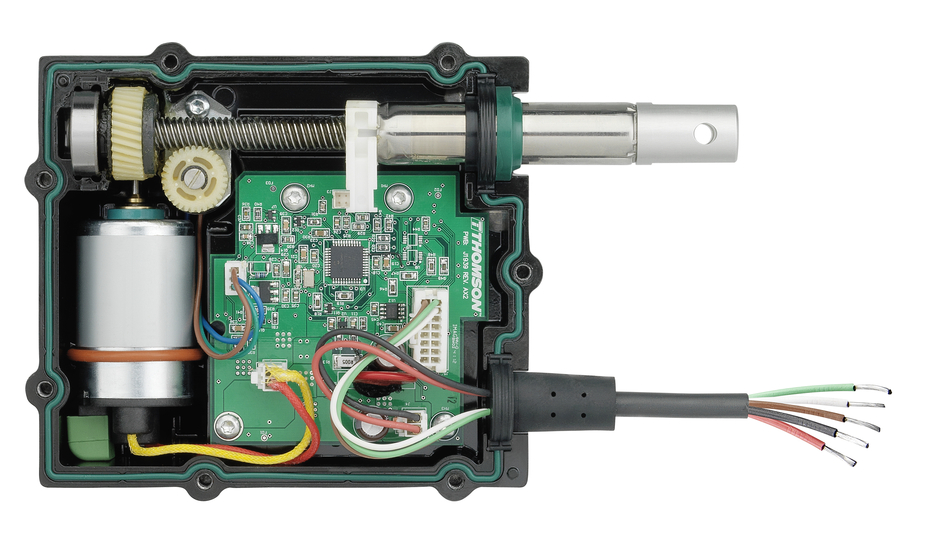

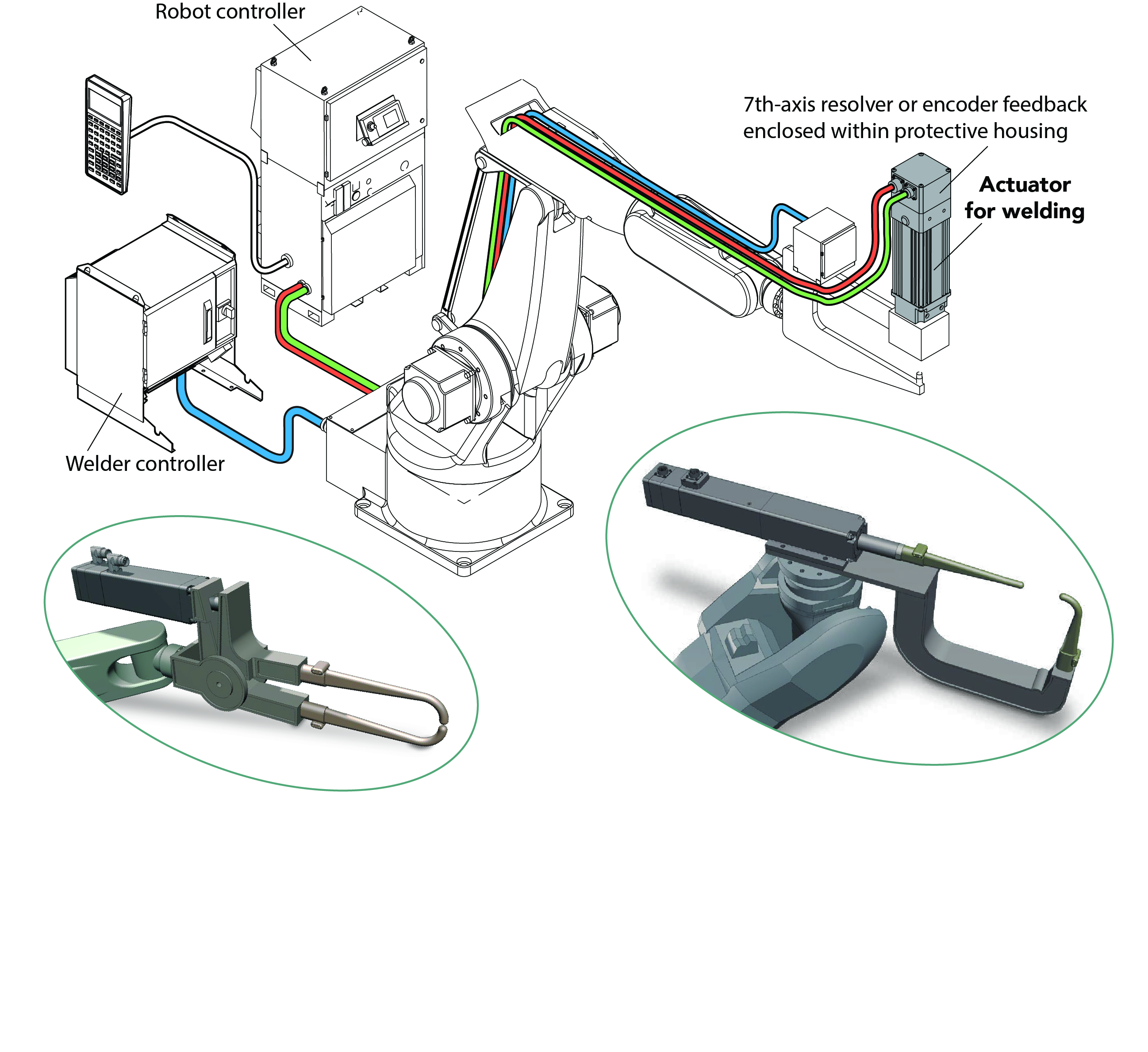

Another benefit for applications that must deliver different outputs over time is that many electric actuators are programmable, so can adapt to changing conditions. Exceptions abound, but applications with similar dynamics generally make use of similar actuators—those that pair motors with ballscrews; incorporate brushless dc motors; use leadscrews; come in a rod style; integrate belt-and-pulley setups; use motors paired with planetary roller screws; or are fully integrated actuators with built-in guides.

Note that electric actuators that work closed-loop or with a micro-stepping motor can match force and speed output commands best using feedback to overcome most of the mechanical limitations of rotary-to-linear devices.

Some application tips: No matter the application, establish the design’s power draw. Determine if the machine needs continuous or intermittent power draw, as that will dictate actuator size and type. Remember that overly large electric actuators can be less responsive than properly sized units.

On the other hand, appropriate safety factors ensure that electric actuators run coolly. Plus, lighter loads on the mechanical components can extend life. Halving load on a leadscrew can extend its life eightfold, for example.

Also account for the application environment and any dirt, chemicals and liquids that will contact the actuator. O-rings and seals must be made of materials that withstand the application’s suite of contaminants. Finally, ensure that the electric actuator can handle the application’s side, radial and axial loads.

Technology applications:

Matching actuators to design demands

Electric actuators for automation applications must deliver set levels of speed and force requirements. Here, better feedback and controls can increase responsiveness to overcome any mechanical limitations while boosting output-motion accuracy. OEMs and end users can pick from a vast array of actuators to get the right level of accuracy—for everything from lumber-processing machines to those medical applications that need accuracy to a few micrometers. Electric-motor actuators that use belts and acme screws for rotary-to-linear conversion of motion abound. That said, the majority of general motion applications (including positioning tables, workpiece-pivoting stations, robotic end effectors and machining axes) make use of actuators that integrate ballscrews. With precision of down to micrometers, these satisfy designs that need thrust to thousands of pounds-force or linear positioning speeds to several feet per second.

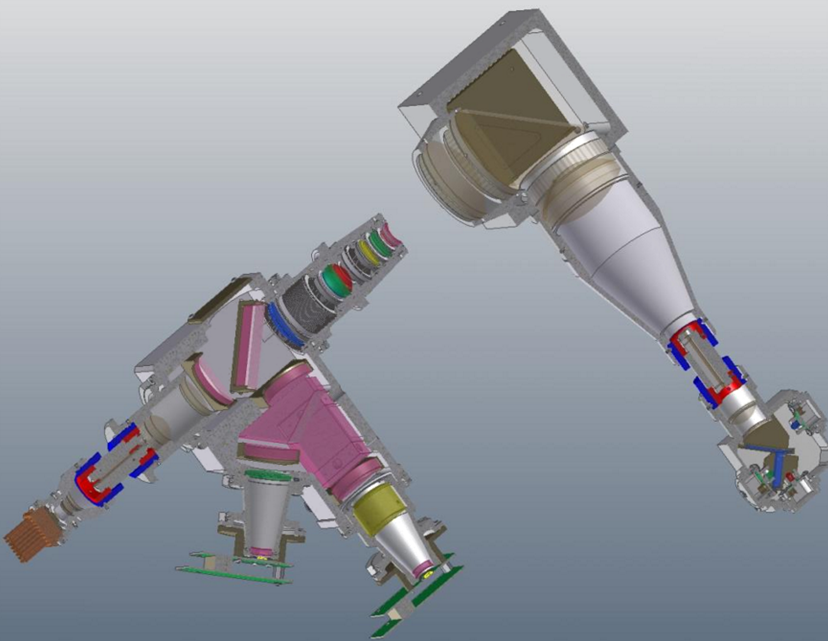

Elsewhere, on injection-molding applications, packaging machines, machine presses and other setups that need high thrust, actuators that pair the electric motor with a roller screw (sporting a nut loaded with roller bearings that work like planetary gears around the screw) is a newer and increasingly common option. Typical stroke is 2 m with acceleration to a few gs.

|

Common actuator types |

Benefits and potential limitations |

Typical uses |

|

Actuators pairing motors |

• High axial output force for given torque input (mechanical advantage) • Speed and stroke limits |

Industrial, transportation, aerospace and defense |

|

Actuators with brushless dc motors |

• None of the wear of brush motors; long life • More costly initially and potentially complicated drive |

General-purpose applications; axes run at high speed; appliances; factory automation |

|

Actuators with leadscrews |

• Simplicity and (in some versions) integration of guide function • Variable life due to sliding wear |

Ruggedized equipment; lower-cost consumer products; machine-tool transport |

|

Rod-style actuators |

• High force output (especially screw-driven types); hygienic • Seals can increase cost |

Medical applications needing sealed motion components; sorting and food processing |

|

Actuators with belt-and-pulley setups |

• Extremely high speeds and long strokes; short design lead times • Limited precision without guides |

Horizontal and vertical designs; small conveying to large SCARA transport |

|

Fully integrated actuators |

• Simple installation • Less design freedom |

Consumer products to medium-volume industrial machines |

|

Linear motors |

• Fast and accurate • More costly than alternatives |

Ultra-high-precision applications in semiconductor, medical and more |

|

Motor paired with planetary roller screw |

• Fast, accurate and precise • More demanding installation requirements |

Precision applications in aerospace and semiconductor |

Leave a Reply

You must be logged in to post a comment.