← PREVIOUS PAGE || “Battery-powered equipment is spurring more demand for high-efficiency dc motors,” said Paul McGrath, national sales manager at maxon precision motors. “Here, we supply motors for robots that navigate retail stores to check inventory and verify that items are placed on shelves in the proper locations — often during an end-of-the-day surveillance sweeps. Some of our motors get efficiencies to 90% — far better than the 60% for comparable motor offerings.”

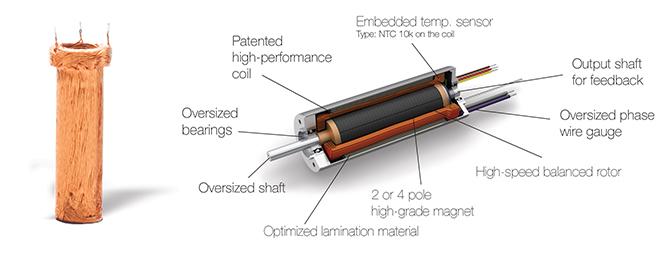

Ironless-core motors in particular eliminate the losses of iron components; coreless motors from the motor maker also avoid the stray losses of laminate cores. Permanent magnets in both brush and brushless offerings further support maximal efficiency.

In some cases, software can predict motor-system efficiencies. One such application lets engineers check the performance of different motor technologies based on key parameters. “So an engineer may have different voltage options available for a battery-operated device and need to know the efficiency of a motion solution at those different voltages,” said Dave Beckstoffer of Portescap. “Using MotionCompass software here, design engineers can quickly test different voltages to see changes in the design’s efficiency (and power) — and get information that normally would’ve required testing in a lab.” This shortens the engineering time and reduces iterations to get to a final design.

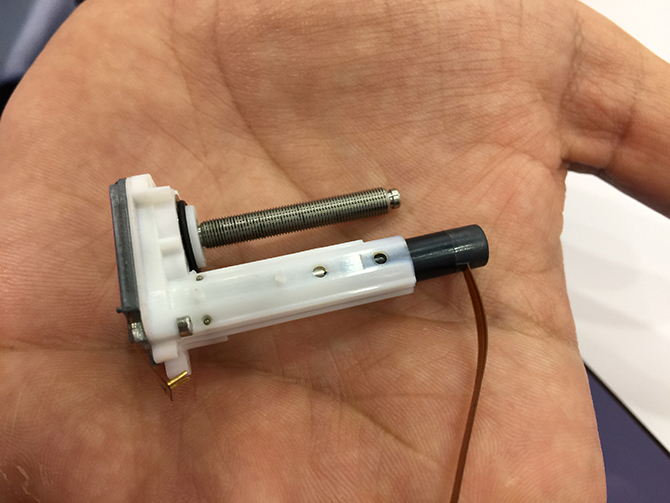

Where mobile designs such as AGVs and utility-task vehicles use electric motors for embedded robotics, it’s often a frameless permanent-magnet motor that directly integrates into the wheel drive and runs off low voltage, according to Osak of Electromate. “In our marketplace, size requirements are increasingly challenging — with torque-density requirements also increasing … and that’s especially true for motion designs that run off low-voltage battery-operated systems,” he added.

Others agree. “Automated guided vehicles (AGVs) and other battery-powered equipment certainly require compactness. We see a trend towards higher-torque-density motors with integrated drive electronics as opposed to traditional BLDC motors with separate drives,” said Rice of Applied Motion Products ⚙️ NEXT PAGE →

Leave a Reply

You must be logged in to post a comment.