One of the unique characteristics of servo systems is that they operate in closed-loop mode. This means they use feedback—from a resolver or encoder on the motor, and sometimes from an encoder on the load—to compare the commanded value (typically position, speed, or torque) with the value that was actually reached. Based on this feedback, the controller initiates movements to correct any deviation between the commanded and actual values.

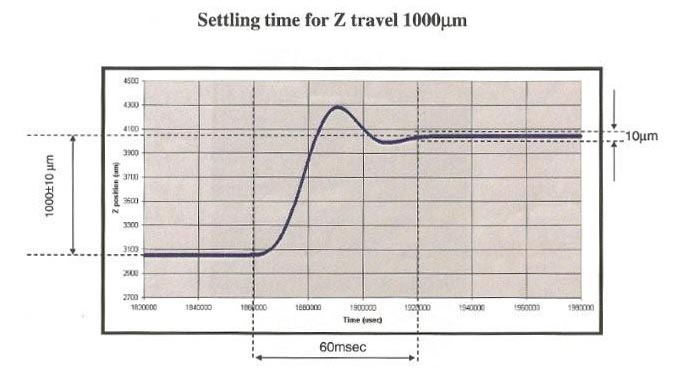

Feedback is necessary because the motor doesn’t always (in fact, rarely) reach the intended position on execution of the initial command. This is due to the fact that mechanical systems are not perfectly stiff—they will always have some “springiness” to them. Belts are not perfectly rigid, ball screws have compliance, and even couplings and gearboxes experience windup. Because of these mechanical inaccuracies and compliance, the system requires time to “hunt for” and settle on the correct position. The time the system takes to achieve and maintain a specified range (typically 2 – 5%) around the commanded value is known as settling time.

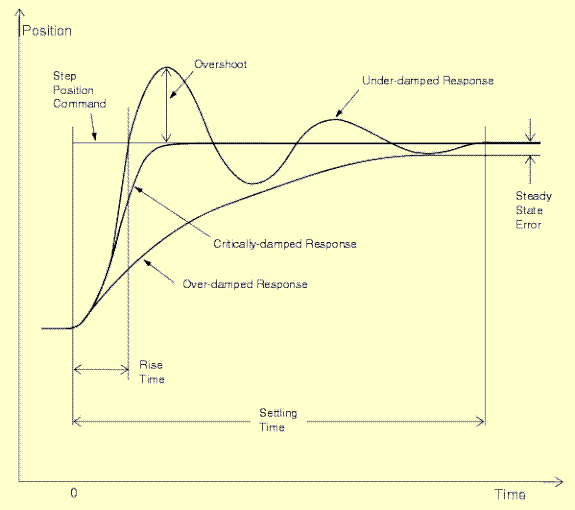

Image credit: Parker Hannifin Corporation

To control settling time, one of the parameters that is adjusted during servo drive tuning is the damping ratio. The damping ratio influences the system’s approach to the commanded value and its response to correction or compensation commands. There are several types of damping, with the three most common being over-damped, under-damped, and critically damped.

Image credit: Adept Technology, Inc.

Over-damped systems take a conservative view of motion control, approaching the commanded value slowly to avoid overshoot and minimize settling time. However, an over-damped system exhibits slow response and is not suitable for highly dynamic applications.

An under-damped system gives a faster response time, approaching the commanded value quickly. However, this results in a large overshoot and oscillations around the commanded position. These oscillations are known as ringing, and decrease over time until the target value is reached (within the specified error).

Critically damped systems are a hybrid between over- and under-damped systems, achieving a balance between fast response and short settling times. A critically-damped system approaches the commanded value with a slight overshoot, which minimizes ringing and reduces settling time. In most applications, the goal is to achieve critically damped response.

Servo tuning affects settling time through electronic manipulation of the system, but settling time can also be reduced through mechanical considerations, by using components with high stiffness, by reducing the moved mass as much as possible, and by using design and construction methods that provide structural dampening to the system.

Leave a Reply

You must be logged in to post a comment.