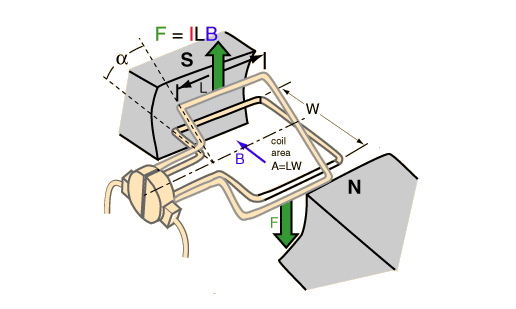

The operating principle of a DC motor is based on the interaction between the magnetic field of a rotating armature and the magnetic field of a fixed stator. As the north pole of the armature is attracted to the south pole of the stator (and vice-versa), a force is produced on the armature, causing it to turn. Commutation is the process of switching the field in the armature windings to produce constant torque in one direction, and the commutator is a device connected to the armature, which enables this switching of current.

Image credit: Georgia State University

The basic purpose of commutation is to ensure that the torque acting on the armature is always in the same direction. The voltage generated in the armature is alternating in nature, and the commutator converts it to direct current. Simply put, the commutator turns the coils on and off to control which direction the electromagnetic fields are pointing. On one side of the coil, the electricity should always flow “away,” and on the other side, electricity should always flow “towards.” This ensures that the torque is always produced in the same direction. Otherwise, the coil would rotate 180 degrees one way, and then switch direction.

For an excellent visual showing how the current is switched due to the position of the coils and brushes, see this article from the University of Utah.

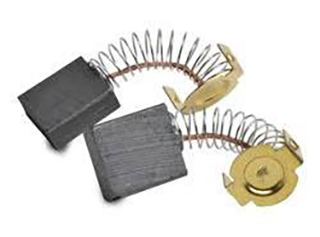

The commutator itself is a split ring, typically made of copper, with each segment of the ring attached to each end of the armature coil. If the armature has multiple coils, the commutator will similarly have multiple segments—one for each end of each coil. Spring-loaded brushes sit on each side of the commutator and make contact with the commutator as it turns, supplying the commutator segments and the corresponding armature coils with voltage.

As the brushes pass over the gaps in the commutator, the supplied electrical charge switches commutator segments, which switches the electrical polarity of the armature coils. This switching of the polarity in the coils maintains the armature’s rotation in one direction. The voltage between brushes fluctuates in amplitude between zero and a maximum value, but always maintains the same polarity.

As mentioned earlier, the commutator is constructed in segments, which are insulated from each other. As the brushes pass from one segment to the other, there is an instant where the brushes contact both segments at the same time. This is referred to as the neutral plane, and at this point, the induced voltage is zero. Otherwise, the brushes would short the ends of the coil together and cause sparking due to high voltage.

It’s important to note that the discussion above relates to traditional brushed DC motors, which are commutated by mechanical means. Brushless DC motors also require commutation, but for brushless designs, commutation is carried out electronically, via an encoder or Hall effect sensors that monitor the position of the rotor to determine when and how to energize the coils.

Feature image credit: Groschopp, Inc.

Leave a Reply

You must be logged in to post a comment.