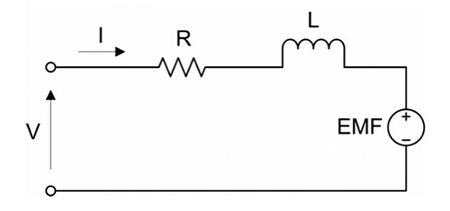

The operation of a DC motor is relatively straightforward. A coil is placed in a magnetic field, and when an electric current passes through the coil, a torque is produced, causing the motor to turn. The entire process is driven by applying electrical power to the coil, with the source voltage having a direct relationship to the motor’s output speed. To understand this relationship between voltage and speed, let’s look at a typical brushed dc motor circuit.

The applied voltage equals the voltage drop across the coil resistance, R, and the inductor, L, plus the back-EMF.

Where:

V = applied voltage

I = current

R = resistance

L = inductance

E = back-EMF

The voltage equation can be simplified by assuming that the current is constant, in which case inductance can be disregarded:

The back-EMF (electromotive force) is a voltage that is generated by the rotation of the coil. It opposes the applied voltage, reducing the voltage flowing through the motor. Back-EMF is calculated as:

Where:

kE = electrical constant, inherent to the motor

ω = angular velocity of the motor

Substituting for E in the voltage equation, we get:

The current, I, through the motor coil is directly related to the motor’s torque:

Which can be rearranged as:

Where:

T = torque

kT = torque constant, inherent to the motor

Substituting for I, the voltage equation now becomes:

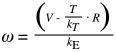

This shows the direct relationship between the applied voltage and the motor’s angular velocity. Rearranging to solve for the angular velocity:

For DC motors, the torque and electrical constants, kT and kE, are equal, so the angular velocity equation can be simplified to:

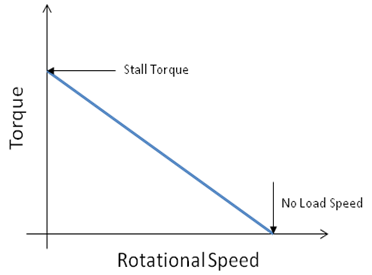

From this we can see that the motor’s maximum speed occurs when there’s no load (torque) on the motor.

Rearranging for torque:

Similarly, maximum torque occurs when angular velocity is zero.

These two relationships can be seen in a typical DC motor’s torque-speed curve.

Image credit: National Instruments Corporation

Back to the original question: how does voltage affect speed? From the analysis above, we can see that when the load (torque) on the motor is constant, speed is directly proportional to supply voltage. And, when the voltage remains constant, an increase in the load (torque) on the motor results in a decrease in speed.

Feature image credit: MICROMO

Leave a Reply

You must be logged in to post a comment.