One feature of stepper motors that differentiates them from other motor types — particularly servo motors — is that they exhibit holding torque. This means that when the windings are energized but the rotor is stationary, the motor can hold the load in place. But a stepper motor can also hold a load in place when there is no current applied to the windings (for example, in a power-off condition). This is commonly known as the detent torque or residual torque.

Detent torque

Stated another way, detent torque is the amount of torque the motor produces when the windings are not energized. The effect of detent torque can be felt when moving the motor shaft by hand, in the form of torque pulsations or cogging.

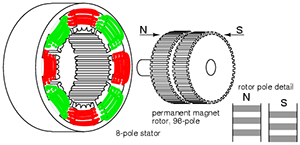

Of the three types of stepper motors — variable reluctance, permanent magnet, and hybrid — only variable reluctance motors do not exhibit detent torque. This is due to the difference in construction between variable reluctance motors versus permanent magnet and hybrid designs. Both permanent magnet and hybrid stepper motors use a permanent magnet rotor, which is attracted to the poles of the stator even when there is no power to the stator windings. Variable reluctance motors, on the other hand, use a passive (non-magnetized) rotor made of soft iron; therefore, there is no attraction between the rotor and the stator when the stator windings are not energized. Hybrid stepper motors incorporate teeth on the surface of the rotor, so they are able to better manage the magnetic flux between the stator and rotor, which gives them higher holding, dynamic, and detent torque values than permanent magnet steppers.

Image credit: allaboutcircuits.com

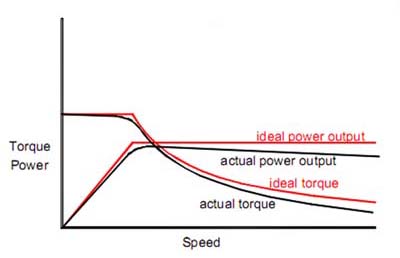

Because detent torque has to be overcome before the motor will move, it reduces the ideal torque the motor can produce when it’s running. The amount of power the motor needs to produce to overcome the detent torque is proportional to the motor’s speed. So the faster the motor turns, the greater the effect detent torque will have on the motor’s actual torque output.

Image credit: Geckodrive Motor Controls

On the other hand, detent torque can be beneficial when stopping the motor. The momentum of the moving rotor is countered by the detent torque, along with friction in the rotating components. Therefore, a higher detent torque will help the motor stop more quickly. Detent torque typically ranges from 5 to 20 percent of the motor’s holding torque.

Holding torque

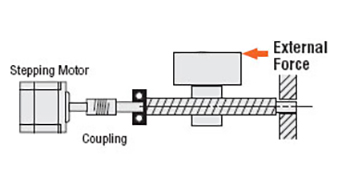

A stepper motor’s holding torque is the amount of torque needed in order to move the motor one full step when the windings are energized but the rotor is stationary. Holding torque is one of the primary benefits that stepper motors offer versus servo motors, making stepper designs a good choice for cases where a load needs to be held in place.

Image credit: Oriental Motor U.S.A. Corp

Holding torque is typically higher than running torque, and is limited primarily by the maximum current the motor can withstand. From a practical standpoint, holding torque is the sum of the magnetic force exerted by the coils to hold the motor’s current position, plus the detent torque. Once the motor is moving, the torque available at low speeds equals the holding torque minus two times the detent torque (because the motor has to work against the detent torque).

Leave a Reply

You must be logged in to post a comment.