Absolute rotary encoders output precise position information—even after a power-off condition—by assigning a unique digital value, or “word,” to each shaft position. But in applications where the encoder makes more than one revolution during the process, there is no way to know how many turns it has completed. At least not with the traditional type of rotary encoder, also known as a single-turn encoder. It uses one code disk, and the digital position values are repeated for each revolution of the encoder. For applications where the full range of positions doesn’t exceed one revolution of the encoder, a single-turn version is suitable. A good example is a rotary table, where the table makes no more than one revolution in either direction.

When the measuring task takes place over more than one revolution of the encoder, the application will require a multi-turn version. Multi-turn encoders are able to track the absolute position because the digital position value is not repeated until the maximum number of rotations (typically up to 4096) is reached. This is especially important for applications where the motion is linear, such as electromechanical actuators.

Image credit: A-Tech Instruments Ltd.

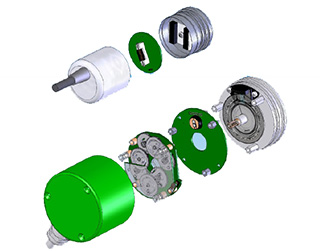

The most common multi-turn encoders use multiple disks connected by gears to track the number of revolutions. The advantage of geared designs is that they eliminate the need for batteries to store position information. However, they tend to be larger than non-geared types due to the size of the gear train, and they introduce mechanical elements that can wear or break.

Another multi-turn rotary encoder design uses an electronic counter with a battery backup. This technology is more compact and mechanically reliable since it doesn’t contain complex gearing. The downside of encoders with battery backup is the need to periodically check and replace the battery.

A third technology, found in some magnetic rotary encoders, is based on the Wiegand effect, in which energy is generated from the moving encoder shaft through the use of a specially conditioned wire, known as a Wiegand wire, which rapidly changes polarity when it encounters an alternating external magnetic field. This produces a short but strong pulse of energy in a coil wrapped around the wire. This energy triggers the turn counter and writes the data in non-volatile memory. Wiegand effect encoders eliminate both batteries and additional mechanical elements, but because of the low energy levels produced, they may not be suitable for heavy-duty applications.

Position information from an absolute encoder is transmitted by parallel, serial, or bus communication. Parallel communication requires a separate wire for each bit of data, so it becomes impractical at higher resolutions, where the number of wires would be cumbersome and costly. Since multi-turn encoders can transmit 30 or more bits, they are generally above the practical limit for parallel communication and instead use either fieldbus (Profibus, for example) or serial (SSI, for example) communication to simplify wiring.

Image credit: SICK Inc.

Feature image credit: A-Tech Instruments Ltd.

Leave a Reply

You must be logged in to post a comment.