Resolvers and encoders are both devices that measure the rotary position of a shaft by converting mechanical motion into an electrical signal. Resolvers have a longer history, originally used in military applications and adopted for industrial use due to their rugged design. But encoders are taking the place of resolvers in many applications. What’s driving the shift from resolvers to encoders, and when does each technology make sense?

Resolvers for harsh environments

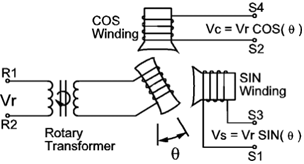

A resolver is similar in design to a motor, consisting of a rotor with a primary (reference) winding and a stator with two secondary windings—sine (SIN) and cosine (COS)—that are phased 90 degrees mechanically apart. When an AC voltage is applied to the rotor winding, voltages are then induced in the stator windings. These voltages are equal to the value of the reference voltage multiplied by the sine or cosine of the input shaft’s angle from a zero point. The ratio of the voltages represents the absolute position of the input shaft, and a resolver to digital converter (RDC) compares the two voltages to determine the shaft position.

Image credit: Advanced Micro Controls, Inc.

The advantages that resolvers offer over encoders make them better suited for extremely harsh applications, such as military and aerospace equipment. One of the most significant benefits of resolvers is their lack of sensitive optics, which allows them to withstand much higher vibrations and shock loads than encoders. They are also resistant to electrical disturbances. And without solid state electronics, they can withstand much higher temperatures than encoders and have a higher overall durability.

Encoders for accuracy and simplicity

Despite these advantages, encoders are winning out as the technology of choice in many applications. One reason for this is the relative complexity of integrating a resolver into a system. The converter and filtering circuitry required to convert a resolver’s analog signal must be carefully integrated and “tuned” to the drive system. These electronics can cost multiple times (3-5x) the resolver itself, making a resolver system very expensive. Encoders, on the other hand, are digital devices, so their integration into control systems is relatively simple and doesn’t require complex electronics or circuitry.

From a performance standpoint, encoders have a lower weight and rotational inertia than resolvers, making them more suitable for applications with high acceleration and deceleration rates. In addition, the conversion rate of the RDC limits a resolver’s maximum speed, and resolvers lose some accuracy when the application encounters rapid speed changes, as is often the case with servo motors. Encoder accuracy is typically in the range of 20 arcseconds, which is much better than the 3 arcminute range of resolver accuracy. Another advantage that makes encoders a more attractive option is that they can be upgraded by replacing the feedback element and changing software, whereas changing a resolver would potentially require a change in the converter, filter, supply voltage and frequency.

Weighing the benefits and drawbacks of both resolvers and encoders, the deciding factor on which is the best alternative will often be environment. For applications that involve shock loads, vibrations, or high temperatures, resolvers are a more robust solution. But encoder designs are becoming more rugged and reliable, and they can now withstand conditions that would previously require a resolver. This improved durability, in conjunction with their ease of use, explains why encoders are becoming the preferred choice over resolvers.

Leave a Reply

You must be logged in to post a comment.