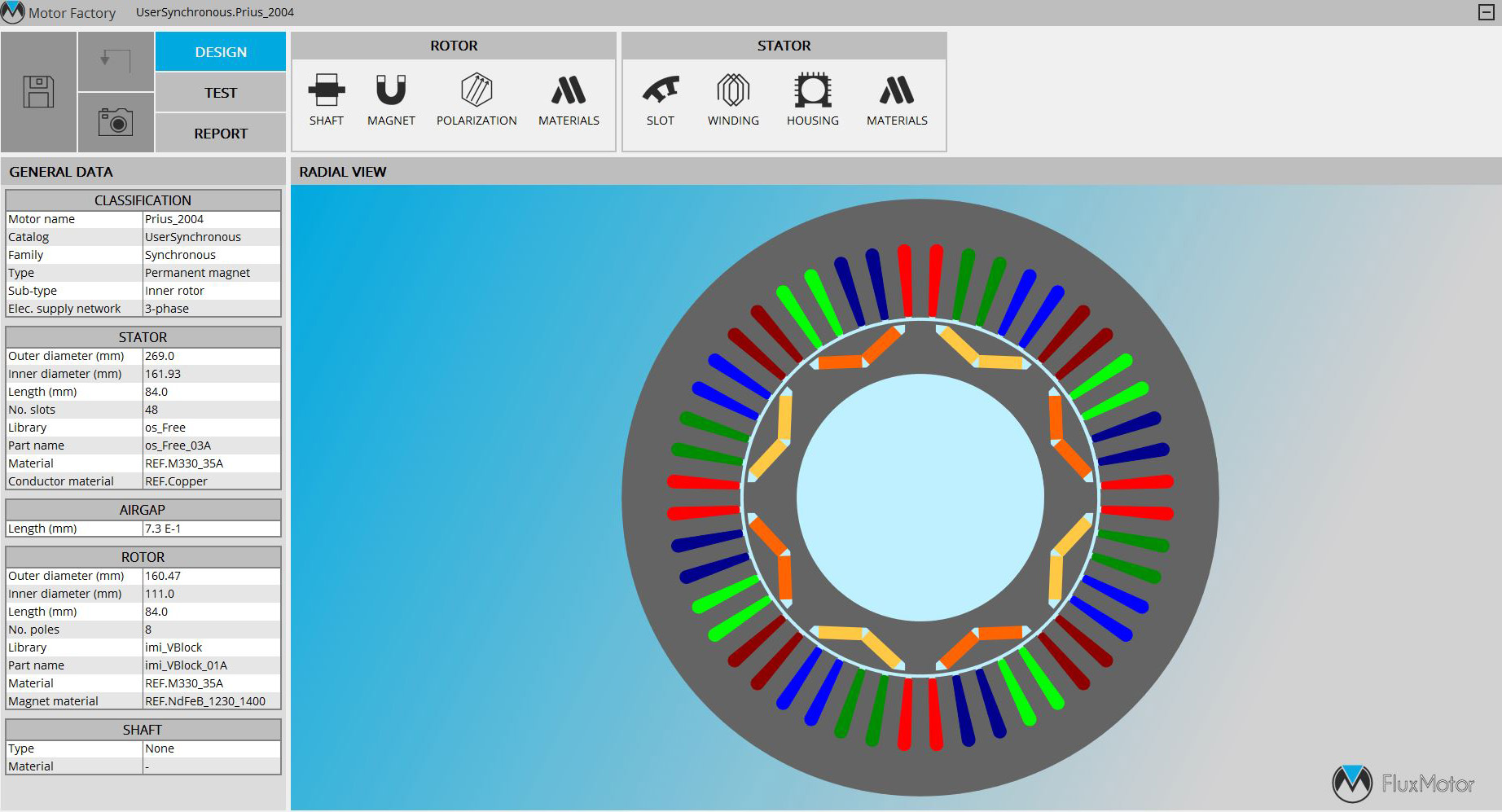

Altair now offers FluxMotor , a dedicated platform focusing on the pre-design of electric rotating machines. FluxMotor is part of Altair’s HyperWorks CAE Suite, which includes Flux the leading software for low frequency electromagnetic and thermal simulations. The software tool allows users to design and create machines from standard or customized parts, as well as to intuitively add windings and materials to run a selection of tests and compare machine capacity.

“FluxMotor is an easy-to-use and efficient dedicated predesign tool, targeting designers from all sectors related to the electric motors field,” says Grégory Michaud, Electromagnetic Engineer at SoftBank Robotics, who was involved in the testing phase of the new software together with the development team.

Appealing to a broad range of users such as designers and manufacturers of electrical rotating motors, the software allows motor specialists to define machines and assess their technical-economic potential within minutes. FluxMotor’s efficient working environment ensures a better visualization of machine performance, enabling fast and accurate computations which can easily be connected to Flux finite element software and other tools within the HyperWorks suite for more advance studies, including multiphysics optimization capabilities.

Benefits of FluxMotor software

Dynamic libraries offer standard or customized options ready to be used to compose motors.

Facilitated project management, allow a quick access to past studies and to manage the full range of products.

Computing methods wisely using the high power of finite element modeling.

Automatically driven workflow offering an efficient user-oriented environment to different level of users.

Capabilities of FluxMotor simulation software

- A design environment, with dedicated interface, helps motorists to finalize machine, step by step within minutes. Four different winding modes help users to find the right winding architecture.

- Parts Library focuses on the visualization and choice of parts; standard libraries are available. Standard parts, magnets and slots can be edited and customized for unlimited configuration. Comprehensive and scalable material database. Automated standard and relevant tests ready to be performed.

- The motor catalogue environment allows easy management of motors and projects, helping the user to classify the machine and offers a quick access to past studies.

“We wanted to develop an easy to use software without compromising on accuracy. FluxMotor helps reduce computing time to a minimum while still maintaining accurate results,” explains Fabrice Marion, Program Manager for FluxMotor at Altair. Learn more about FluxMotor at an introductory webinar on Tuesday, June 13th at 10am EDT.

Altair is focused on the development and broad application of simulation technology to synthesize and optimize designs, processes and decisions for improved business performance. Privately held with more than 2,000 employees, Altair is headquartered in Troy, Michigan, USA and operates more than 50 offices throughout 22 countries. Today, Altair serves more than 5,000 corporate clients across broad industry segments. To learn more, please visit www.altair.com.

Leave a Reply

You must be logged in to post a comment.