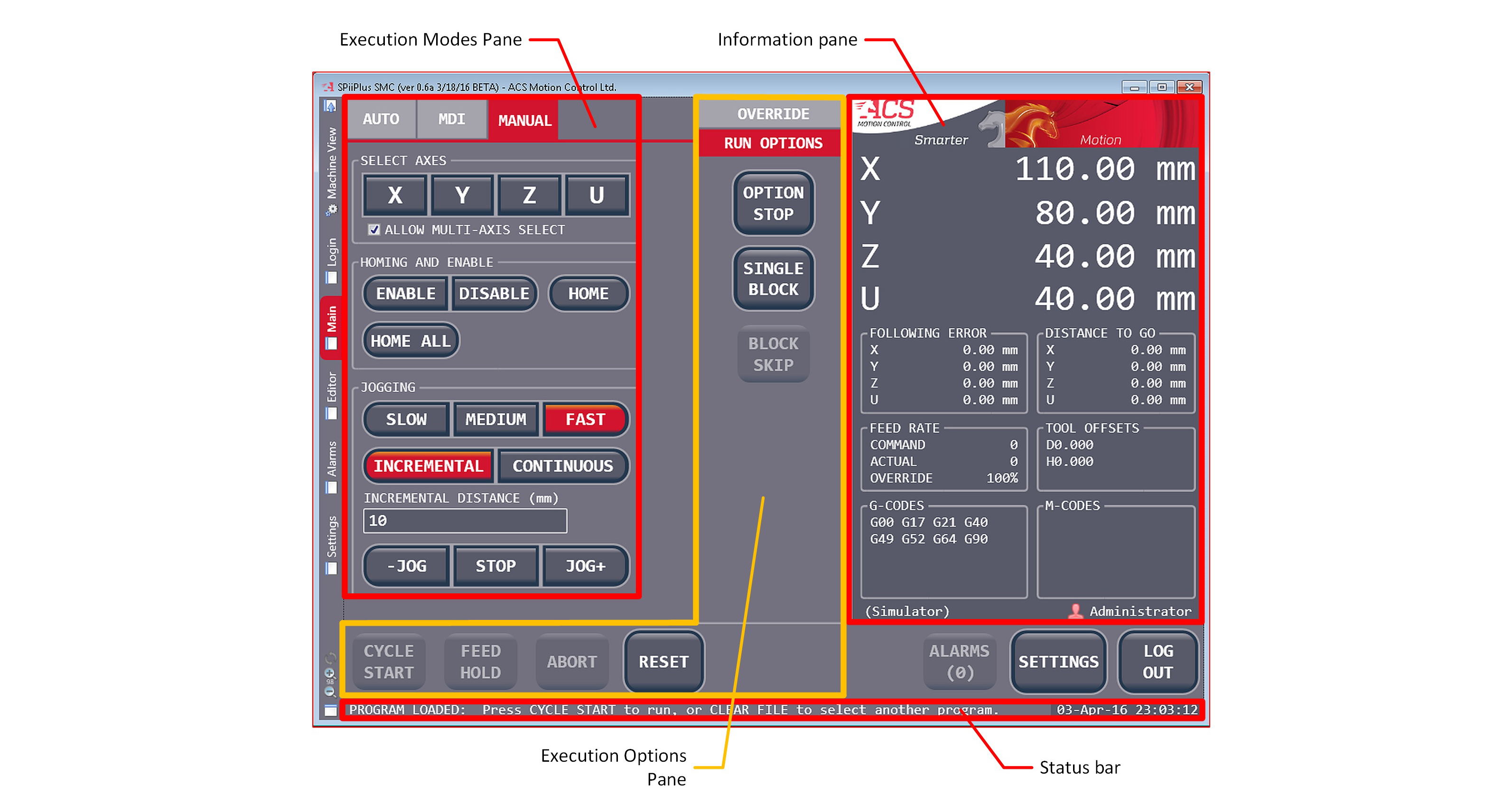

ACS Motion Control has developed a customizable CNC HMI Platform for high precision machining and processing applications. Designed with simplicity, flexibility and ease of customization in mind, the SPiiPlusSMC (smart motion commander) software platform significantly reduces the effort and time spent by the machine builder on developing and maintaining HMI software.

Leveraging a SPiiPlus EtherCAT® based control system, the SPiiPlusSMC HMI platform offers complete, high precision CNC control.

“Instead of investing significant effort to develop and maintain a CNC human machine interface, a machine builder using SPiiPlusSMC software can focus on optimizing the application and improving machine performance. This results in shorter time to market and greater machine accuracy, precision, and throughput,” said Jason Goerges, Product Marketing Manager.

The SPiiPlusSMC CNC HMI software platform is ideal for OEMs and system integrators of high precision machining and material processing equipment such as laser cutting, processing and micromachining; precision grinding; additive manufacturing, and more.

Suitable for any PC running Windows 7/8/10, XP with SP3, the SPiiPlusSMC software is optimized to require minimal Windows resources. Customization options are available through ACS and its partners, or via user created plugins.

For more information on the SPiiPlusSMC software, visitacsmotioncontrol.com/spiiplussmc.

Leave a Reply

You must be logged in to post a comment.