From packaging to communications, BLDC servomotors are gaining market share in a variety of industries — and for good reason. They deliver high torque and smooth rotation (with minimal torque ripple) and lend themselves well to cost-saving customization.

By Ralph Adams • President | Orbex Group

Design engineers typically rely on off-the-shelf brushless dc (BLDC) motors as standalone components to work into their designs. But oftentimes it makes more sense to order custom motors — especially where it’s impossible to satisfy application requirements with catalog components.

Stock motors by definition are a “take what you get” proposition when it comes to size and performance. In contrast, custom BLDC motors and motor assemblies can be designed to fit in tight or irregular spaces without sacrificing torque density. Motors can also be customized for demanding operating environments — whether the threat is thermal, corrosive, or electromagnetic.

Another reason to specify custom BLDC motors is to improve cost. One might assume that custom solutions are costly … but in many applications, the opposite is true. That’s because custom motor assemblies allow feature integration that can ultimately minimize the number of components on the bill of materials — and the assembly time necessary for putting all those components together.

Quick note: BLDC motors versus stepper motors

Our focus in this article in on customizing BLDC motors. In fact, the high torque and compact size of BLDC motors has meant they’re increasingly common in today’s dynamic servo applications. They can even outperform designs traditionally run by stepper motors — primarily by improving the performance of servo machines … as well as lowering maintenance requirements.

Of course, stepper motors (especially newer closed-loop variations) excel on several motion-axis types. However, motion designs needing advanced position control and high shaft speeds as well as space savings often necessitate BLDC motors. More specifically, many of these torque-dense motors offer power output that’s roughly triple that of equivalent stepper motors. This difference is due to the high number of poles that stepper motors need to deliver precise positioning under open-loop control. BLDC motors on the other hand deliver top precision sans any sacrifice to rotational speed or torque. No wonder BLDC motors are a top choice on everything from robotic arms to packaging machines needing higher-speed motions under closed-loop control.

Example one: Custom BLDC motors on AGV wheels

One emerging application for BLDC motor customization is automated guided vehicles or AGVs. AGVs have come to be indispensable in futureproofed factories and automated warehouses. Because BLDC motors deliver reliable performance across various speeds and torque ranges, they’re a good fit for continuously rotating joints in robotic vehicles. Case in point: One new AGV design employs two custom BLDC motors …

The AGV’s first motor is a 2-kW 120-mm-frame motor with integral brake and encoder —as well as an optional wheel and tire. This motor integrates a compact yet torque-capable roller reducer directly coupled to the motor output. This arrangement increases driveline stiffness — and saves space and cost.

The AGV’s second motor is a similar smaller system based on a 1-kW 80-mm-frame motor. It delivers gear ratios down to 16:1 — which in turn allow speeds to 2 meters per sec. It also boasts high radial load capabilities (for carts with 2,000-lb payloads) and incorporates optional case rotation. That lets engineers center the loads to be carried by the AGV over the motor’s output bearings to minimize moment loading.

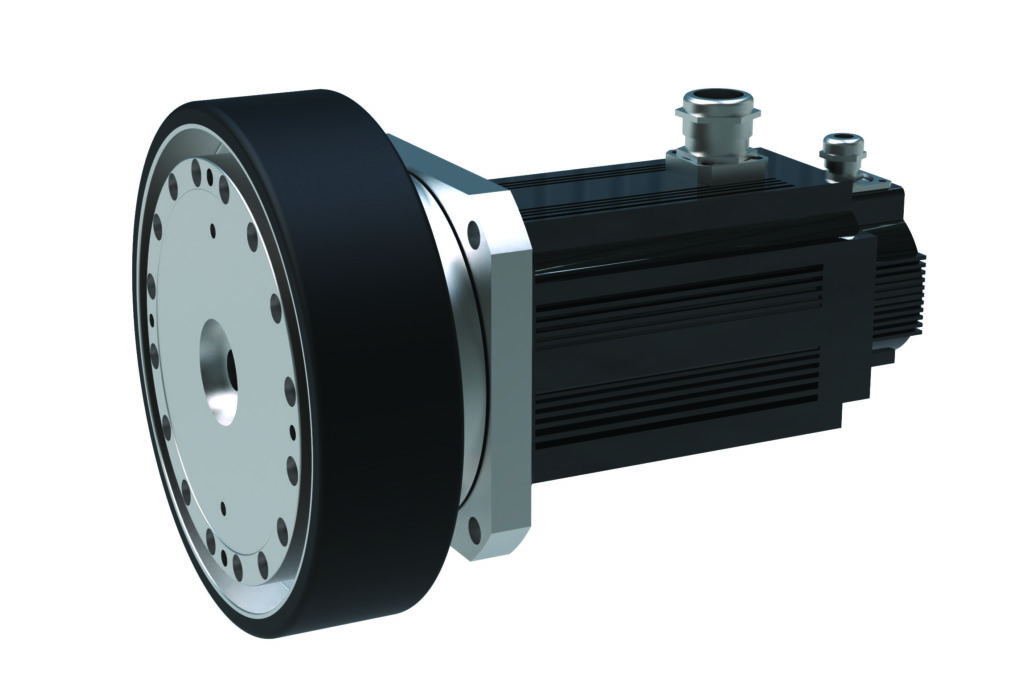

Example two: Custom through-hole table for inspection of heavy workpieces

For another machine build in an inspection and sorting process having challenging load, speed, and size requirements, supplier engineers configured and integrated a rotary through-hole table and servomotor. The through-hole tables leverage the advantages of servomotors, cam dividers, and direct-drive motors for top precision and rigidity (at a fraction of the cost of similar tables based solely on direct-drive motor technology). In fact, the complete actuation solution rotates parts weighing up to 40 lb under a sensor array for inspection — and does so at 200 rpm … even while having a low-profile design to fit into existing workcells.

For this design, the supplier engineers combined an Orbex Group HPM60 200 V servomotor with a THT85 through-hole table to outperform other tables based on mechanical rotary indexing as well as direct-drive motors.

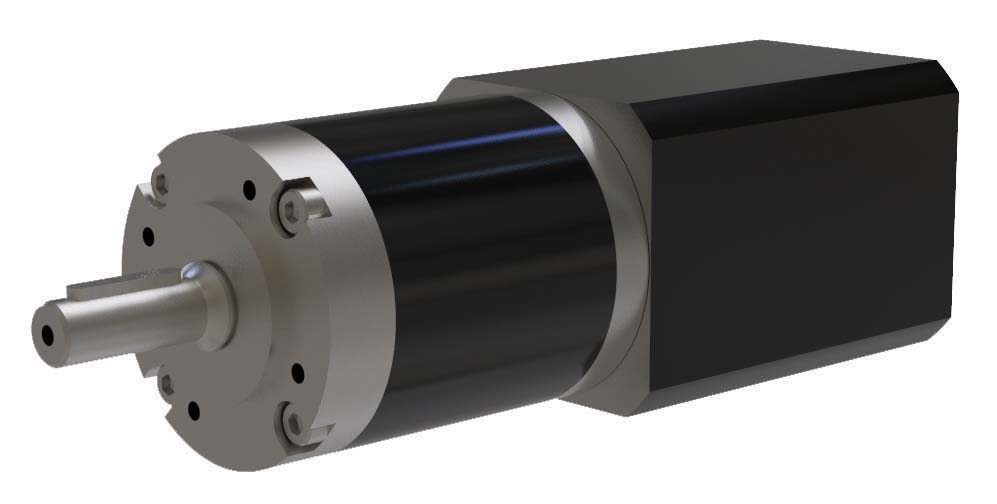

Example three: Custom BLDC motor with planetary gear reducer

Yet another motion-control application employs a custom BLDC motor with an integral planetary gear reducer. The optimized motor helps the machine meet various speed, voltage, and mounting requirements — and its high-quality assembly maximizes controllability. More specifically, the OEM for this application needed a brushless gearmotor for a motion-control application requiring:

• A short overall length

• A planetary reducer with a 25:1 gear ratio

• Use of 48-Vdc bus voltage

• High-resolution encoder feedback

• Commutation signals

• Torque output of more than 2.5 Nm at 160 rpm

The supplier’s engineering team tackled this application by modifying a BLDC motor (the Orbex Group EC4260) with a special shaft to allow direct mounting to a two-stage planetary reducer. This feature eliminated the need for costly adapter plates and internal couplings — which trimmed cost and overall design length. In addition, the supplier engineers optimized the motor’s winding to run off the 48-Vdc bus voltage as specified. These modifications let the motor reach high speeds with minimal current draw. Completing the package is an integrated 16,384-count magnetic encoder. The added resolution allows superior servo control and better stability.

The modifications and pre-integration also prevented component overspecification — for a right-sized assembly costing less than $200.

Orbex Group | www.orbexgroup.com

Leave a Reply

You must be logged in to post a comment.