Mechanical overrunning clutches, sometimes called one-way or backstop clutches depending on the context, transmit torque in one drive direction but let the output axis continue to turn (freewheel) when the driving motor slows or stops. Such clutch function is useful in large and small designs for material handling, packaging, conveying, medical, turbine auxiliary drives, and off-highway applications.

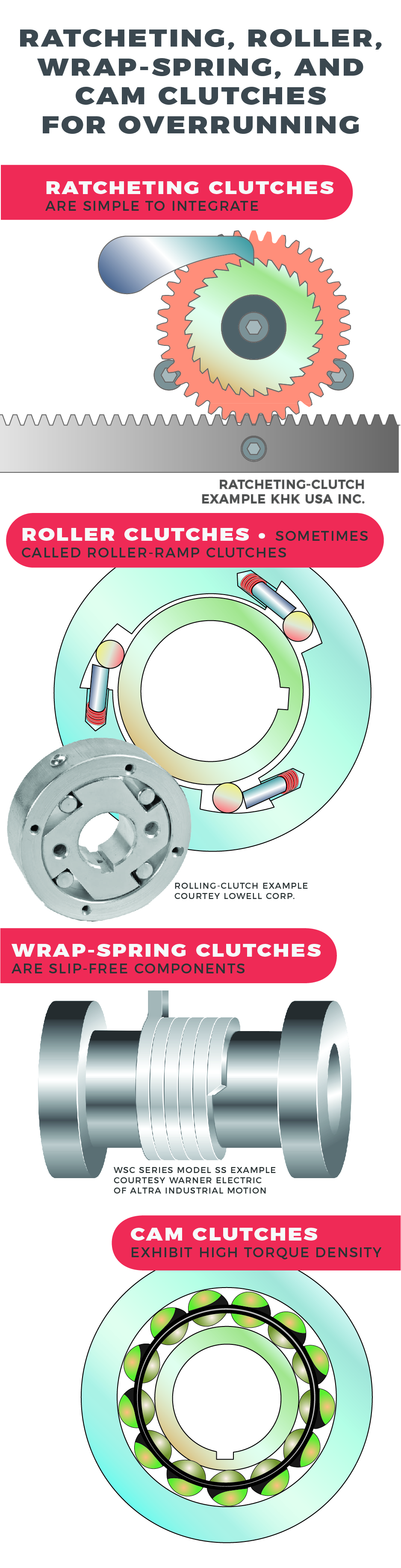

Common mechanical overrunning clutches include those that use ratcheting, roller ramps, wrap-spring, and cam action for one-way axis engagement.

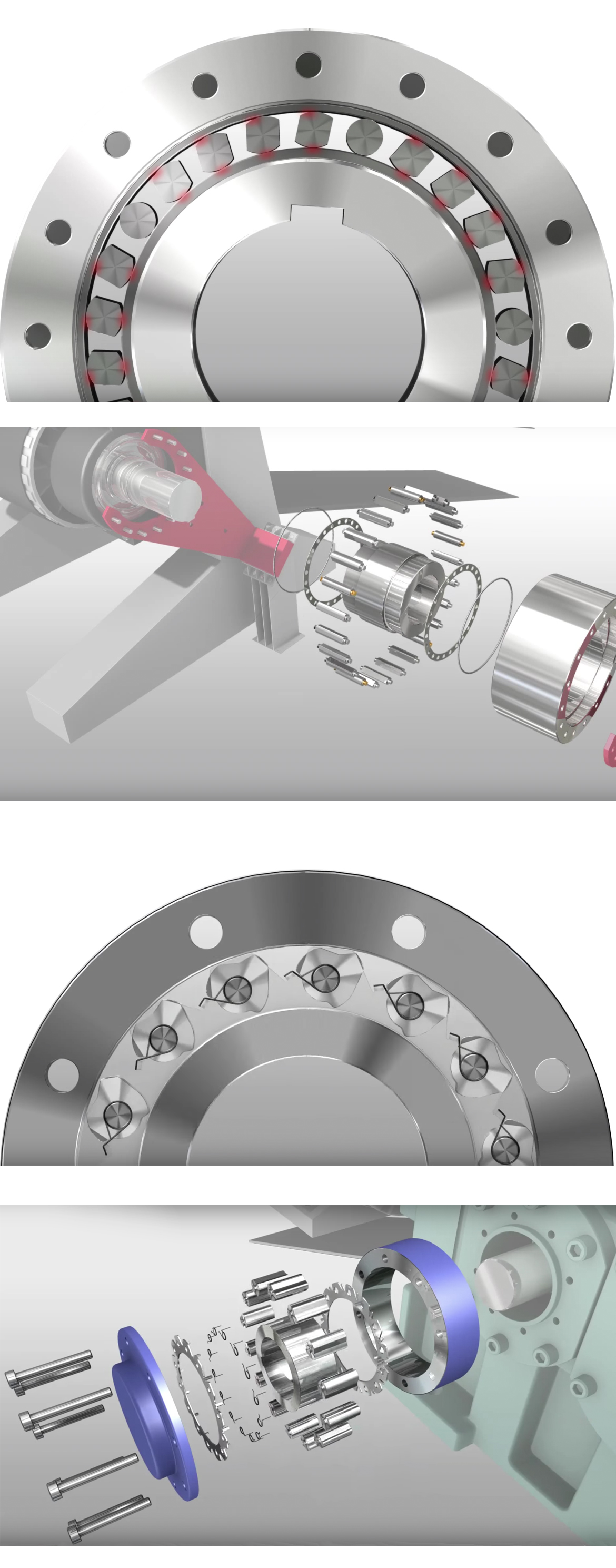

Of these designs, cam clutches (sometimes called sprag clutches, especially in transportation industries) are relatively new and power dense. An array of bars profiled with asymmetrical cam-shaped geometry ring the circumference of the clutch. Cages at each end keep the bar cams evenly spaced. Upon input rotation, the cams act as rising wedges to lock between the races on the inner and outer clutch halves.

More specifically, cams in some cam-clutch variations fill the space between the races to quickly act as a sprags and hold the clutch halves together via locking friction. Upon reversal, the cams quickly release (and then tolerate high overrunning speeds). In other cam-clutch designs, centrifugal force makes the bar cams turn into liftoff to disengage the clutch halves. Then upon slowing or reversal, a spring at each cam pushes them back into sprag-type engagement.

No matter the variation, the geometry of cam clutches’ load-bearing cams tightly pack into the clutch body. That means it’s often two other factors that limit torque capacity:

- Bore size (and connecting shaft size with it)

- The effects of tangential forces where the cams meet the races.

But some cam clutches exhibit comparably less ID and OD race deflection and contact stress than other designs thanks to distributed loading during engagement. That in turn extends life and makes for smoother engagement. Some cam clutches even use ground alloy-steel races to maximize uniformity of load distribution. Because jamming under load can occur where wear is excessive, some cam clutches for demanding applications feature precision-formed cams to resist wear and prevent failure from fatigue.

As mentioned, other overrunning clutches include those that use ratcheting, roller ramp, and wrap-spring action.

Ratcheting clutches are basic two-element clutches that use a single-tooth arm that engages a toothed wheel in one direction and freewheels in the other. These are most common in powered consumer products and light industrial tools.

Roller-ramp clutches engage through ground steel rollers that run and lock on a wheel precision machined with incline ramps. Note that some roller-ramp clutch literature describes roller engagement with a cam. This isn’t to be confused with the cam arrays of cam clutches, as here the cam is singular and refers to the assembly’s wheel that’s machined with ramps.

Operation relies on concentricity between inner and outer races, so most roller-ramp clutch iterations include compression springs to maintain roller-to-wheel contact. The springs install at angles engineered to optimize initial actuation and holding grip. Because of the way the cylindrical rollers lock into flat steps on the inner wheel, these clutches transmit high torque and withstand high overrunning speeds. In addition, roller-ramp clutches are low cost and easy to repair even while offering high overrunning speed and torques.

Wrap-spring clutches have springs that coil around a cylindrical output to tighten down when turned in the drive direction. This creates friction to lock the assembly and transmit torque. Wrap-spring clutches excel in applications of moderate speed — commonly to 2,000 rpm or so.

Leave a Reply

You must be logged in to post a comment.