Internationally active manufacturers of machine tools, 3D printers and related systems often provide their customers with the choice between two to three CNC controllers to cover regional preferences. While doing so, they follow a common-part strategy below the drive level as much as possible in order to reduce costs and complexity. In addition to interfaces for CNC controllers from Bosch Rexroth and Siemens, IMS-A now supports FANUC automation systems. With these options, start-up only takes a few minutes. With the Plug & Play linear encoder system, the person performing the start-up merely has to determine the respective zero point of the machine and the position offset. The IMS-A electronic nameplate transfers all other information.

Internationally active manufacturers of machine tools, 3D printers and related systems often provide their customers with the choice between two to three CNC controllers to cover regional preferences. While doing so, they follow a common-part strategy below the drive level as much as possible in order to reduce costs and complexity. In addition to interfaces for CNC controllers from Bosch Rexroth and Siemens, IMS-A now supports FANUC automation systems. With these options, start-up only takes a few minutes. With the Plug & Play linear encoder system, the person performing the start-up merely has to determine the respective zero point of the machine and the position offset. The IMS-A electronic nameplate transfers all other information.

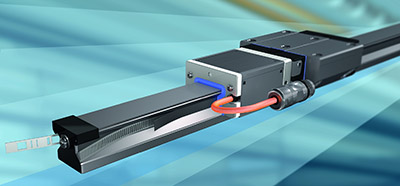

The absolute position measuring system integrated into the linear guides operates without contact and is therefore wear-free. Through its intregration in the runner block and superior sealing, machine manufacturers can avoid energy-intensive air sealing systems, even in working areas with metalworking fluids, dust, chips and other contaminants. In other words, the regular replacement or cleaning work that would usually be necessary for glass scales in these environments is no longer required with the IMS-A. In a comprehensive series of tests, Bosch Rexroth has investigated the effect of a mixture of ferromagnetic laser cutting dust and grease lubricant directly on the scale. Almost all of the paste-like mixture was wiped away by the standard sealing system of the runner block and the absolute position measuring accuracy was always met.

The measuring system is resistant to magnetic fields like those emitting/emitted from linear motors. Protected against vibrations and shocks, the sensors and evaluation electronics are placed in a housing on the end face of the runner block. Design engineers save the space normally reserved for external measuring systems. Rail guides equipped with the IMS-A fit into existing machine designs without any mechanical redesign. The absolute position is transferred with a resolution of 25 nm for all interfaces, while the repeatability is better than +/- 0.25 μm. The integrated scale is available at an accuracy of up to +/- 3 μm/m. With the IMS-A, users can implement several runner blocks on an up to 4,500 mm long profile rail independently and without any limitations on accuracy. The wear-free IMS-A does not require a battery for buffering the position. Even after a power failure, the measuring system still reports the exact position of the axis upon being switched on again from the integrated absolute scale without a homing cycle.

Bosch Rexroth Corp.

boschrexroth-us.com

Leave a Reply

You must be logged in to post a comment.