The Interroll Group, the leading global provider of material handling setups, is bringing a new generation of belt drives to the North American market. This innovative motor platform is predominantly for modern conveyor belt systems in manufacturing, food and beverage, distribution centers and airports. It features a completely modular design and offers both synchronous and asynchronous drive setups. Initially, drum motors with a diameter of 80 mm will be offered; additional sizes will be rolled out in near future.

Check out Interroll’s Belt Drive Matchmaker tool here.

Check out Interroll’s Belt Drive Matchmaker tool here.

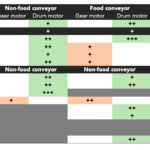

The new platform makes it easy to combine all of the components and guarantees short and reliable delivery times. Furthermore, all of the options, such as encoders, brakes and return stops, are now available for all of the platform’s motor variants. This makes it significantly easier for system integrators and equipment manufacturers to plan and implement efficient material handling setups. In addition, all of the drum motors in the new design are IP69K rated; this makes them more hygienic as the cleaning process is easier and much less time consuming, especially when compared with gear motors.

“The needs of customers and users are the highest priority. Thanks to the consistent platform strategy, we add value to their operations by providing highest quality, better delivery time and fast and effective service. With the new drum motor platform, it once more appears that innovation isn’t an end in itself for Interroll. As a global technology leader in internal logistics, the aim of the company’s innovations is always to offer the customer significant added value,” said Tim McGill, President of Interroll North America.

New-generation belt drives extend service life and boost flexibility — as well as efficiency

The new-generation belt drives have a number of design benefits. Stronger shafts and ball bearings guarantee a long service life, and a robust planetary gear makes it possible to efficiently transfer high torques to the belts while making very little operating noise. Thanks to an expanded number of gear stages, a larger speed range can be covered. So it’s particularly easy for system integrators and equipment manufacturers to implement a conveyor setup in accordance with their individual throughput specifications.

The new platform’s modular design reduces production and delivery times. Furthermore, the new generation of drum motors stands out as a plug-and-play setup thanks to the advantages offered during installation and maintenance. That means the power supply can be established using a simple plug-in connection. This significantly reduces downtime for maintenance and repair work, resulting in considerable cost advantages for the user.

Drum motors from Interroll offer users an extraordinarily high level of energy efficiency. When compared to alternative drive systems, these motors demonstrate a significantly reduced loss of power. This leads to a drastic reduction in operating costs for the user.

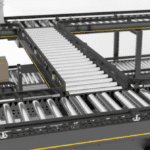

Interroll will also be displaying its successful Modular Conveyor Platform with RollerDrive and 4-zone certified MultiControl Card. The MCP is a suitable setup for conveying and sorting multiple types of totes, boxes and items, as well as feeding packaging and labelling machines and several other applications in the food, beverage and pharmaceutical sectors.

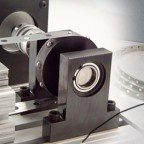

Last but not least, Interroll will showcase its patented Magnetic Speed Controller MSC50, the most cost-effective setup currently on the market for controlling the speed of boxes and plastic trays traveling on gravity roller conveyors and spirals or the end sections of sorters, suitable for handling goods weighing up to 77 pounds.

Visitors to Pack Expo 2017 — the international trade show for packaging, food and beverage — can experience the new generation of belt drives and the rest of the lineup at Interroll’s booth #7356, South Upper Hall. Pack Expo 2017 takes place on September 25-27 in Las Vegas.

The Interroll Group is the leading global provider of material handling setups. The company was founded in 1959 and has been listed on the SIX Swiss Exchange since 1997. Interroll provides system integrators and OEMs with a wide range of platform-based products and services in these categories: Rollers (conveyor rollers), Drives (motors and drives for conveyor systems), Conveyors & Sorters as well as Pallet & Carton Flow (flow storage systems). Interroll setups are used in express and postal services, e-commerce, airports, the food and beverage industry, fashion, and automotive sectors, and many other manufacturing industries. Among the company’s customers are leading brands such as Amazon, Bosch, Coca-Cola, DHL, Nestlé, Procter & Gamble, Siemens, Walmart and Zalando. Headquartered in Switzerland, Interroll has a global network of 32 companies with turnover of around CHF 401.5 million and 2,000 employees (2016).

Leave a Reply

You must be logged in to post a comment.