Reclamation District 108 is a 150-year-old water district located in the Sacramento Valley that provides irrigation, drainage, and flood protection to farms and rural communities in the area. But drainage and flood-control canals in this region pose a risk to adult salmon who return from the sea through the San Francisco Bay to make their way up the Sacramento River to spawn. One wrong turn may find the salmon traveling up dead-end basin drains that put them at risk of becoming trapped and dying without fulfilling their life’s mission of reproduction.

So to prevent this, Grimes, Calif.-based RD108 — in cooperation with the Department of Water Resources, State and Federal fishery agencies and local landowners — contracted help to reconstruct the Wallace Weir … a barrier at the Knights Landing Ridge Cut about 30 miles north-northwest of Sacramento. This cut is where (especially during flooding) most fish were entering the rural floodplain with no bypasses or return passages to the river.

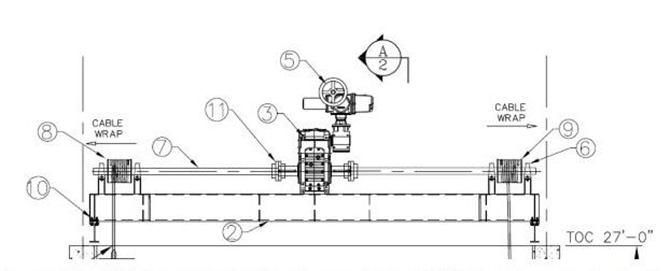

Now the cut includes movable grated barriers (also called picket weirs) to let water flow but prevent salmon from swimming onward. The grates are automated to maintain the picket tips two feet above the water surface.

Six grated barriers hinged to underwater structures (at their bottom edges) connect to cables on their top corners to act as large automated flaps. When meeting a screen in the raised position, salmon bump into its diagonal underside. Their instinctual behavior here is to turn around and seek another route.

Each of the six grates is individually raised and lowered by its own dedicated hoist. The original version of the hoist was engineered by Murray McCaig (now of Municipal Treatment Equipment) and two other designers in 1983 for use on water-control gates. The original stayed stationary once set … so if an operator closed the gate, it remained closed until an operator reopened it.

But the fish-barrier application faced a complicating design problem. Debris buildup on the grates during flooding could induce sudden and unpredictable spikes in force at levels sufficient to pose structural risk to both the grates and their hoists. So the design’s engineers decided the grates had to automatically lower without intervention in such situations … to a level just sufficient to allow debris to be swept over the gate.

That’s when Murray McCaig contracted Barnard Hydro Solutions to devise a mechanism that would lower the grates automatically upon overload.

“We quickly realized that using load cells, controllers, and electric actuators to open the fish screens would be insufficient and too slow to effectively dissipate the sudden loads,” explained Jeff Barnard, P.Eng. for Barnard Hydro Solutions Inc. “That’s why we pursued use of a torque-limiting device into the existing design.”

Custom-designed torque limiter gives fish gate quick response

Years ago, Barnard worked for another company employing torque limiters from Mach III Clutch Inc. — torque-limiting couplings that plug directly into the #3 Morse taper inputs of heavy-duty power drills. The drills rotated 2-in. square operating nuts to raise and lower water control gates. Now this product is a Mach III catalog item.

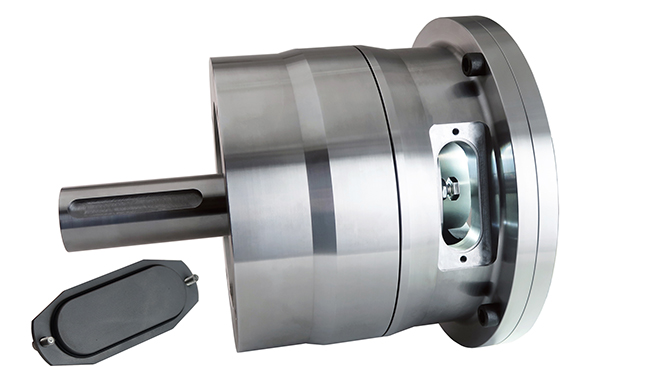

Remembering the torque-limiting solution, Barnard connected with Mach III engineer Ron Ashbrook and worked with Ashbrook on a custom design to mount between the fish gate’s Rototork electric actuator (and SAF77 gearbox) and its parallel helical drive.

The torque limiters to open the fish screens — customized T8C2K-001 mechanical friction torque limiters from Mach III — support the dead weight of the actuator and right-angle gearbox — 255 lb. They withstand constant exposure to the outdoor environment. They also allow in-field adjustments and directly connect to the flanges of the design’s existing components. An enclosed housing has two access ports covered by removable sealed panels; the ports allow access to torque adjustment nuts. In fact, the ports’ width is customized to accommodate an open-end wrench for loosening an internal jam nut; then this nut can be rotated until the target torque is reached … and the jam nut retightened to hold the slip-torque setting.

An adapter plate facilitates connection to the parallel helical drive; the limiter’s housing is designed to support the overhung load of the Rototork actuator and its SEW SA77.

Mach III supplied a total of six T8C2K-001 units — one for each hoist. The torque limiters are B5 flange-mounted units of nonstandard frame size; have a 55-mm input bore and 55-mm output shaft, and total torque capacity to 17,000 lb-in., according to Mach III president Lesli Riehemann. They’re also factory burnished … with slip torque set to 12,967 lb-in. (to within ±10%).

How the final hoist design works

The new hoist systems at the Wallace Weir were placed into service in January 2018, and Reclamation District 108 continues to manage it. The torque limiters hold the 16 x 29-ft grates in the raised position until force against the screen exceeds 13,500 lb. The force then travels back through the helical drive and into the torque limiter, exceeding the set torque value of approximately 13,000 lb-in.

Then the torque limiter’s internal friction and drive surfaces slip against one another to let force on the grate unwind the cables … and lower the grate in the process. Water (and debris) flows over the gate; position sensors detect the change in the grate’s position and send an alarm. An operator is dispatched to the site to reset the grate.

The torque limiters also protect the design’s actuators when the latter are engaged to raise the grates in the event of a jam.

Barnard Hydro Solutions Inc. | barnardhsi.com

Municipal Treatment Equipment Inc. | municipaltreatment.com

Mach III Clutch Inc. | machiii.com

Leave a Reply

You must be logged in to post a comment.