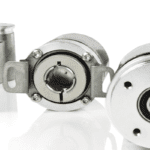

Magnetic absolute encoders are often integrated into motion designs destined for industrial environments or in rough outdoor use. That’s because such encoders are efficient, reliable, and durable — meeting myriad requirements while being efficient as well as economical.

Case in point: Robust MAGRES series magnetic absolute encoders from Baumer operate under conditions in applications all over the world. Now, the new encoder variations EAM580 and EAM360 enable versatile application thanks to their robust magnetic operation and precision communications. Thanks to EN 13849-compliant firmware, it’s possible to integrate the encoders into safety functions up to PLd.

Magnetic absolute encoder for flexible control

With high angular accuracy of ±0.15° the EAM580 and EAM360 absolute encoders ensure efficient control and simplify application design. These magnetic encoders demonstrate their benefits in terms of robustness also in applications which up to now required optical sensing. Thanks to their innovative design and special compensation procedure, their magnetic sensing precision excels by measuring stability and accuracy over temperature, speed and change in direction of rotation.

Magnetic absolute #encoder from @BaumerGroup pairs robustness + precision Click To TweetThe broad product family with several mechanical designs, many mounting and interface options both in 58 and 36-mm design, offers an outstanding selection with maximum flexibility to choose the optimal encoder for the user application. The modular design is not only key to efficiency but also a consistent concept of robustness. For example, the compact 36 mm design integrates the same large ball bearings as the 58 mm variant, and so is equally strong. Another highlight is the bearingless encoder kit, where the magnet rotor is installed separately as an individual component. Without bearings, encoder operation is virtually impervious to wear. Plus, the multiturn variants feature a wide 2 mm air gap for simplified installation.

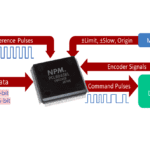

Another focus was on cutting-edge communication technology. Among others, the Profinet variants support the Media Redundancy Protocol (MRP) and the Link Layer Discovery Protocol (LLDP) for neighborhood detection. This way, they increase machine and system uptime and reduce downtime for maintenance.

In fact, the MAGRES EAM encoder firmware was developed based on the EN 13849 standard. So the encoders can be integrated as standard components in embedded software systems certified up to PLd. EAM580 with CANopen interface is also available with redundant sensing. Position is transmitted via two Node IDs which can be checked for plausibility in the control.

Particularly in rough outdoor use — for example, on utility vehicles or mobile cranes — encoders have to endure harmful impacts from all sides. Special stress is imposed via severe shocks and vibration as well as permanent exposure to dust, dirt, water and frost.

The magnetic encoders ensure maximum resistance to shocks up to 500 g and vibration to 30 g. Plus a steel housing ensures high immunity against external magnetic fields. Furthermore, the large and widely-spaced ball bearings endure radial and axial shaft loads to 80 N and 40 N, respectively. The resilient ShaftLock design prevents axial shaft penetration for maximum reliability and resistance even when improperly installed.

An integral part of the new generation is the R-series EAM580R and EAM360R with absolute reliability in permanent operation under extreme conditions, particularly in the mobile automation industry. To meet the high demands on electromagnetic compatibility prevailing in this industry, the electronics are designed and tested for compliance to ECE R10 requirements. The encoders come with C5-M corrosion resistance and IP67 protection in their standard variants. The 0.5 mm2 wire core cross-section enables efficient connectivity by directly attaching the automotive connector.

Applications in wind energy plants have similar high requirements. Particularly for offshore wind turbines reliability is the decisive criterion because any downtime entails high costs. The robust encoder design ensures extreme durability even in harsh climate under adverse conditions. When used for redundant sensing, for example in rotor blade angle alignment, precision plays an important role because measuring differences in two-channel sensing may impair system uptime. Here, the MAGRES series with high angular accuracy of up to ±0.15° is a precise setup for efficient pitch control.

Magnetic encoder that’s IoT ready

Sensor information takes center stage in Industry 4.0 and IoT. Sensor manufacturers face the challenge of having to make the large sensor and interface variety “IoT ready”. EAM580 absolute encoders support the OPC UA communication standard via Profinet, which ensures reliable and non-reactive data exchange among different systems. This open and platform-independent architecture enables easy adaptation to future requirements.

The new encoder generation MAGRES EAM is based on the proven design and the logic further product evolution to ensure even longer lifetime in particularly demanding environments. The broad portfolio is a wide selection going together with outstanding price-performance ratio. For more information, visit www.baumer.com/EAM.

The Baumer Group is one of the worldwide leading manufacturers of sensors, encoders, measuring instruments and components for automated image-processing. Baumer combines innovative technologies and customer-oriented service into intelligent solutions for factory and process automation and offers an unrivalled wide technology and product portfolio. With around 2,400 employees and 38 subsidiaries in 19 countries, the family-owned group of companies is always close to the customer.

Leave a Reply

You must be logged in to post a comment.