Miki Pulley is introducing its CYT Micro Clutches for direct sale to OEM’s in North America. These CYT Clutches are for compact precision applications and may be easily mounted to a driven shaft. Further custom variants can be realized by pairing a sprocket, timing pulley, V-belt pulley or shaft to the armature. More after the jump.

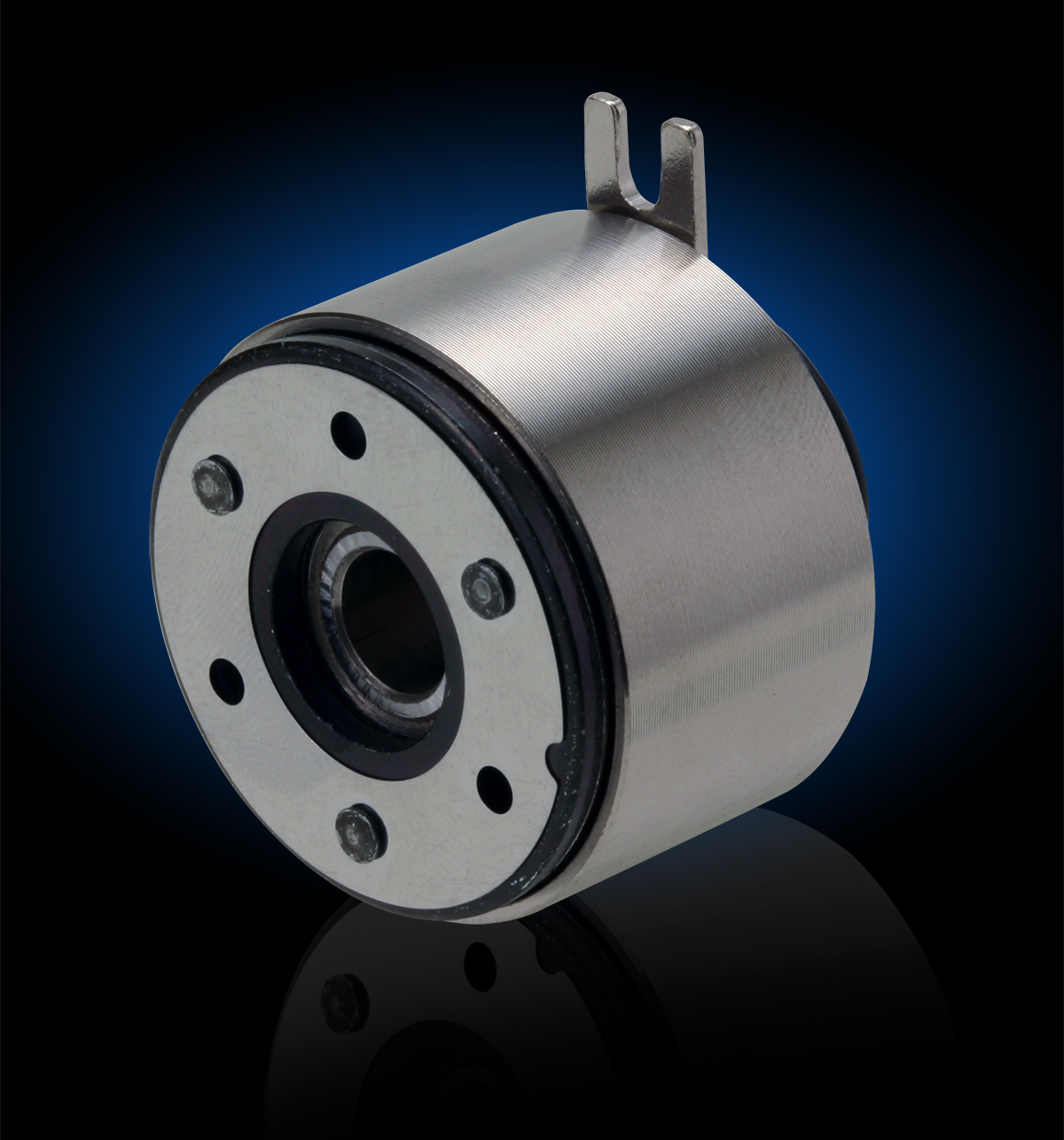

Miki Pulley CYT Clutches accurately connect and release power by being located between the input shaft and the load. The CTY stator is a bearing mounted type of clutch. It provides an efficient connection between a motor and a load with low inertia, minimal drag and long service life.

Two CYT Clutch models are available to accommodate different RPM ranges: a dry metal type and a ball bearing type. In addition, three types of armature configurations are available for pulleys, gears and for combining both on shafts.

Miki Pulley CYT Clutches are durable and versatile with a straightforward design, consisting of clutch stator, rotor and armature. The clutch assembly features an integrated bearing design making mounting fast and easy while ensuring application concentricity and excellent system runout. CYT Clutches operate well in temperatures from +14°F to +104°F (-10°C to +40°C). They have a speed range up to 3,600 rpm.

Available in bores ranging from 6 mm to 10 mm, with clutch torques ranging from 0.3 ft. lbs. to 0.74 ft. lbs. (0.4 Nm – 1.0 Nm). The CYT Clutch utilizes corrosion resistant materials, and is RoHS compliant like all Miki Pulley products.

“Miki Pulley’s CYT Clutches are ideal for compact systems requiring precision operation including printing equipment, packaging machines, and web handling applications.” reports Jon Davidson, Miki Pulley sales specialist. “They are very reliable making them a preferred choice of motion system designers throughout the manufacturing world.”

For more information, call Jon Davidson at (800) 533-1731 or email jdavidson@mikipulley-us.com.

Leave a Reply

You must be logged in to post a comment.