Planetary gearsets offer applications advantages over other gearsets, including multiple kinematic combinations, power density, big reductions from compact setups, and pure torsional reactions. Planetary gearboxes also boost overall design efficiency. Losses never exceed 3% per stage, so the sets transmit most energy for productive motion output. In applications driven by servo systems, gearboxes also reduce settling time … which is otherwise a problem when load inertia is high compared to motor inertia.

Consider the applications of one miniature line of planetary gearing. maxon’s new gear planetary X-series Ultra Performance (GPX UP) is now a standard product offering for configurable X-drive assemblies. So now GPX variations include:

• the GPX A (with metal planetary pins standard)

• the GPX C (ceramic planetary pins for increased torque and life)

• the GPX LN (for reduced noise) and the GPX LZ (for reduced backlash)

• the GPX HP (for high power and increased torque capacity)

• the GPX UP (for ultra performance in the form of smooth back-drivability and top efficiency

GPX UP planetary gearing already works in Mars rovers and Formula 1 racecars to deliver high torque, ruggedness, and efficiency. Normally miniature gear assemblies rotate the planet wheels and gears on greased steel or ceramic pins (which serve as simple plain bearings). In contrast, GPX UP gear assemblies actually include tiny needle bearings at these rotary axes — for rolling instead of sliding friction (and less friction and heat generation).

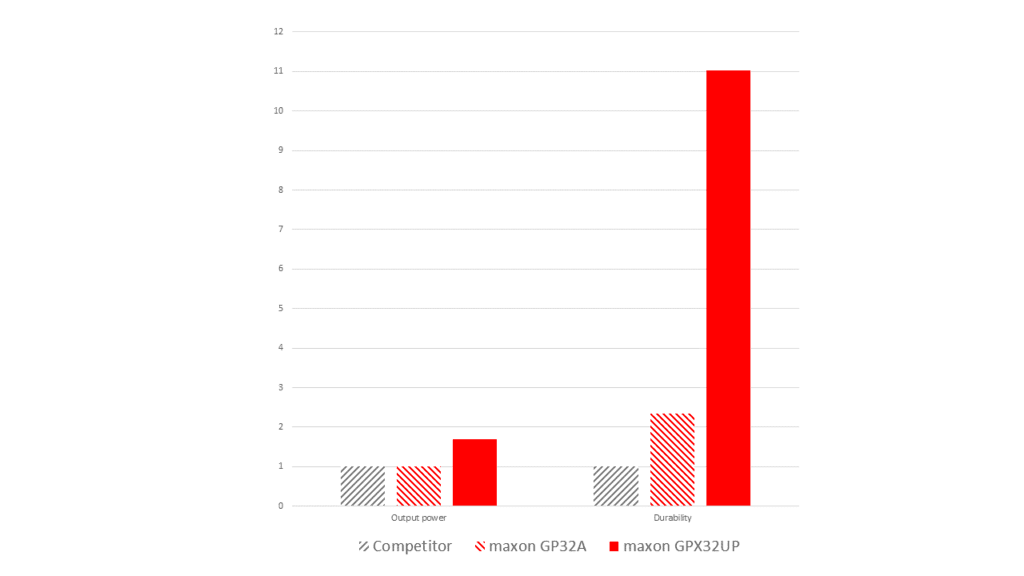

GPX32 UP three-stage assemblies get efficiencies to 90% — far better than the 70% or so of comparable designs. So if fitted with an otherwise identical motor and controller, the entire system can output 30% more torque and power at output … or need 23% less input to generate a given output. If the motor happens to be a brushed motor, that extends the brush and overall system life. Plus more efficient gearing lets the motor operate at a higher location on the efficiency versus torque curve … or allow use of a smaller and lighter motor with control electronics. Such efficiency rom such a small component is particularly useful in battery-powered motion designs.

Having a needle bearings (and not a plain bearing) at the planetary-wheel ID axle means the assembly runs more coolly as well … which is helpful on handheld medical instruments.

Cooler operation also extends the life of the gear assembly’s lubricant — with less thermal stress and abrasive behavior through abraded metal particles and lubricant agglutination … so the GPX UP gearbox lasts 11 times longer than comparable competitor models.

The GPX UP also excels in haptic (force-feedback) applications because its smooth-turning planet gears allow repeatable back-drivability — that turning of the shaft from the output side of the gearbox. So torque feedback via the GPX UP to the motor on the gearing’s input is consistently proportional to the load. Traditionally-built planetary gearheads can’t guarantee smooth back-drivability or consistent load interpretation through the gearbox because of fluctuating efficiency as well as variable tolerance stackups between gearbox internals and the potential cocking of planet gears.

Consider a specific haptic application — that of electronic fly-by-wire flight control. In these systems, a pilot’s steering movements aren’t transferred via conventional mechanical or hydraulic actuators. Instead, electronic transmission occurs via a feel (force feedback) motor assembly in a joystick control column. Such haptics-generating motor assemblies benefit from gearboxes capable smooth back-drivability and simultaneously generating torque and force based on joystick position.

Another haptics application is that of surgical robots for minimally invasive micro and telesurgeries. Doctors performing surgery through these robots dynamically and instantaneously feel forces equivalent to those exerted by the robot end effectors. Here, gearboxes with smooth back-drivability are essential. GPX UP gear assemblies deliver on this parameter even on axes needing gear ratios that necessitate two or three planetary stages. Traditional gearing exhibiting uneven or sticky back-drivability is mechanically noisy and unusable in these robots.

Leave a Reply

You must be logged in to post a comment.