Edited by: Miles Budimir, Senior Editor

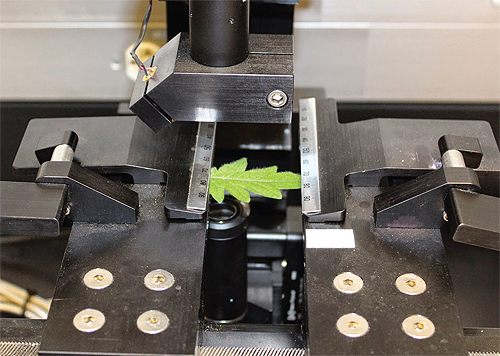

A motion controller is the central piece in an optical system for analyzing plant leaves in a research effort to engineer more drought-tolerant plants. The manufacturer of the optical instrumentation system, Custom Lab Software Systems, used a Galil DMC-4020 to build the Micron Level 3D Confocal Profiling and Thickness Measurement System.

The instrument for optical measurement was designed for Dr. Dan Chitwood, assistant member at the Donald Danforth Plant Science Center. Dr. Chitwood is currently researching how to engineer crops to be resilient to high temperatures and flourish with less water.

The DMC-4020 is used to position perfectly aligned beams from white light confocal displacement sensors and to scan a leaf surface in a predefined pattern. It measures the thickness of the leaves quickly and, when required, can create a detailed 3D morphology of the vascular structure.

The instrument required the capacity to measure up to 10,000 leaves, each with a minimum 200 mm2 surface area, over a two-week period. The time to mount and measure each leaf needed to be one to two minutes. Dr. Chitwood also wanted a comprehensive, easy-to-use and robust user interface. Chitwood analyzed a modified plant’s leaf structure by imaging leaf sections with the sensor to determine the thickness of the leaf and its venation (the arrangement of veins in a leaf), key traits that contribute to drought tolerance.

Once the leaf is mounted using an open frame stage, digital I/O on the DMC-4020 turns on laser line generators used as visual cross hairs, allowing the operator to quickly determine optimum X and Y starting and ending scan positions. A simple mouse click at an X-Y location on a 2D representation of the scan area quickly moves the confocal beam to that position on the leaf. This allows the operator to make a real-time measurement of thickness or to confirm the location for the beginning of the scan.

A PC running a Windows application written in VisualBasic.net sends motion commands to the DMC- 4020 through an RS-232 serial communication port. The goal is to move the stage so that the beam generates a serpentine scanning path over the entire leaf surface to measure thickness at each point along the path to derive average thickness. The DMC-4020 controller uses custom firmware to send precisely timed signals to the dual confocal sensors at fixed distances along the vector path. This low-going Output Compare pulse triggers the two sensors to take each thickness measurement. Once the scan is complete, the 3D data is viewable by the user on the PC as a false color image.

“There are many reasons why we chose the Galil motion controller,” said Terry Chriss, CEO of Custom Lab Software. “The principle reasons were because DMC-4020 had all the features and performance we needed, and the Galil command language is intuitive and easy to learn.”

Chitwood uses genetic resources from naturally drought-resistant wild tomato plants, native to the Atacama Desert of Peru, and analyzes their effects in domestic tomato plants, in an effort to create domestic plants with the wild relative’s resistance to drought.

By using this new technology to measure approximately 10,000 leaves from 76 specially modified domestic tomato lines, comparing the average thickness to the domesticated parent, Chitwood’s laboratory has identified the regions of the genome that have modulated leaf thickness and morphology during evolution and domestication. The long-term goal is to use the analysis to determine what genetic changes are helpful in producing more drought-tolerant, productive tomatoes for a drying planet.

Galil Motion Control Inc.

www.galil.com

Custom Lab Software Systems

www.customlabsoftware.com

Leave a Reply

You must be logged in to post a comment.